Generally yes for axial capacity, but it lowers speed capability; match angle to duty and heat.

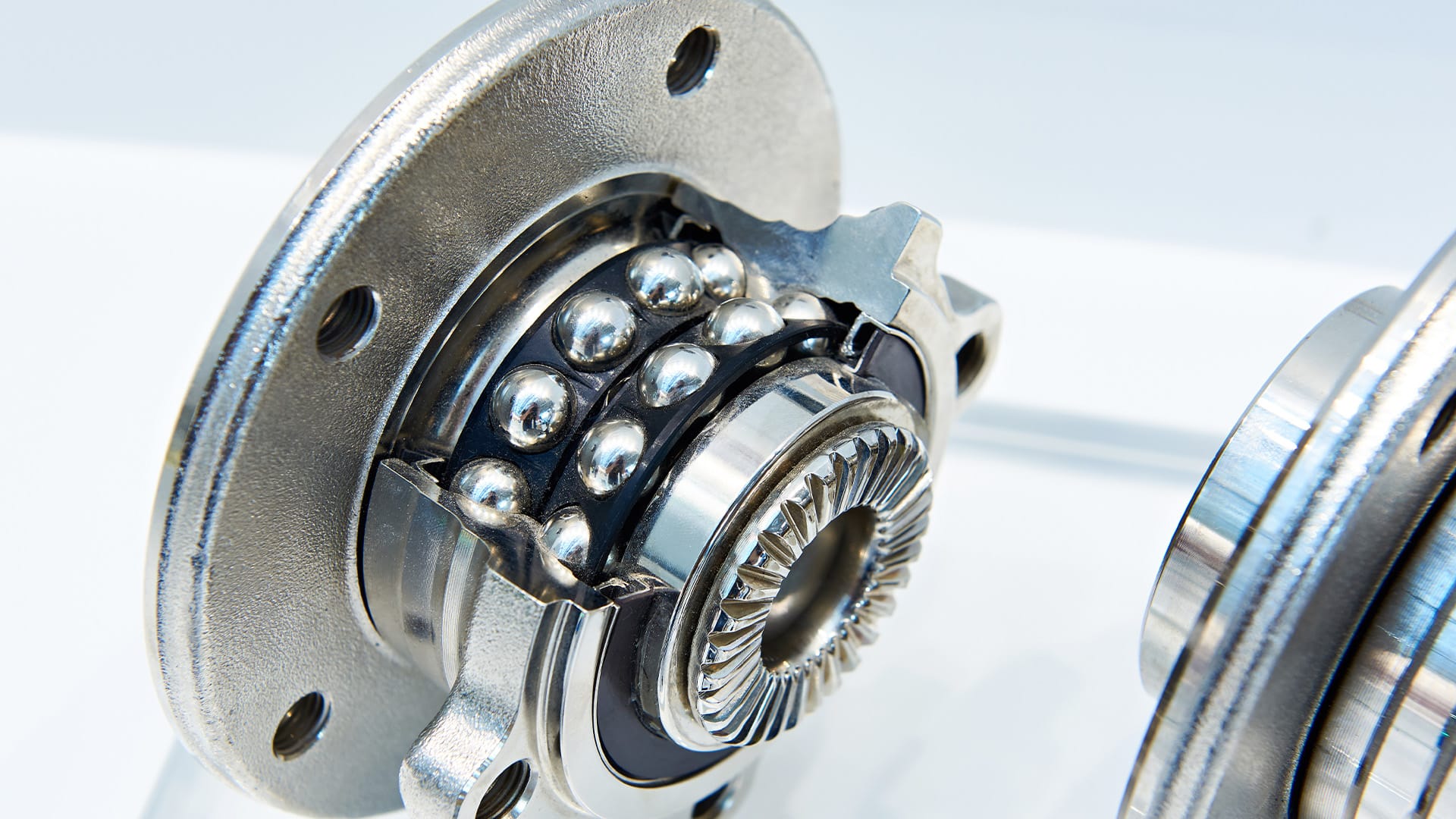

What Is an Angular-Contact Ball Bearing?

Selection Cheatsheet (Load- & Stiffness-First)

- Axial load in one direction dominates: use DT (tandem) pair with appropriate preload; verify thrust direction coverage.

- Axial loads in both directions + high moment stiffness: use DB (back-to-back); highest overturning stiffness.

- Axial loads in both directions + more misalignment tolerance: use DF (face-to-face); slightly less stiffness than DB.

- High speed with moderate axial load: prefer lower contact angle (≈15°) and light preload; ensure skidding is controlled by lubricant choice and preload integrity.

- High axial load / lower speed: prefer higher contact angle (≈25°–40°) and medium/heavy preload within thermal limits.

- Double-row ACBB alternative: compact package for bidirectional thrust without pairing; confirm stiffness vs. matched singles.

- Environment is washdown/caustic: contact seals + deflectors (if sealed variant), cleaner-compatible H1 grease, and corrosion-resistant surfaces.

Environment → Attributes Matrix

| Environment | Material/Coating | Preload & Angle | Fit (shaft/housing)* | Sealing | Lubricant |

| Washdown/food | Stainless or coated rings; stainless/ceramic balls | Light–medium preload; 25° if thrust notable | k5–m6 / H7; verify seal gaps after any coating | Sealed variants or external deflectors | NSF H1; cleaner-compatible |

| Cleanroom/vacuum | Clean, passivated steel; low-outgassing surfaces | Light preload; angle to suit thrust; avoid overheat | Controlled interference to prevent creep | Non-contact shields or labyrinths | Vacuum-suitable oils/greases |

| Abrasive/dust | Coated rings | Medium preload; protect raceways from ingress | k5–m6 / H7; add slingers | Prefer 2RS or shield+labyrinth | Grease with sealing behavior |

| High-speed spindle | Through-hardened steel or hybrid ceramic | Light preload; lower contact angle (≈15°) | Precision fits per OEM; thermal model required | Open with oil/air-oil or low-bleed grease | Low-bleed, high-speed grease or oil |

*Assumes rotating inner ring; adjust for kinematics.

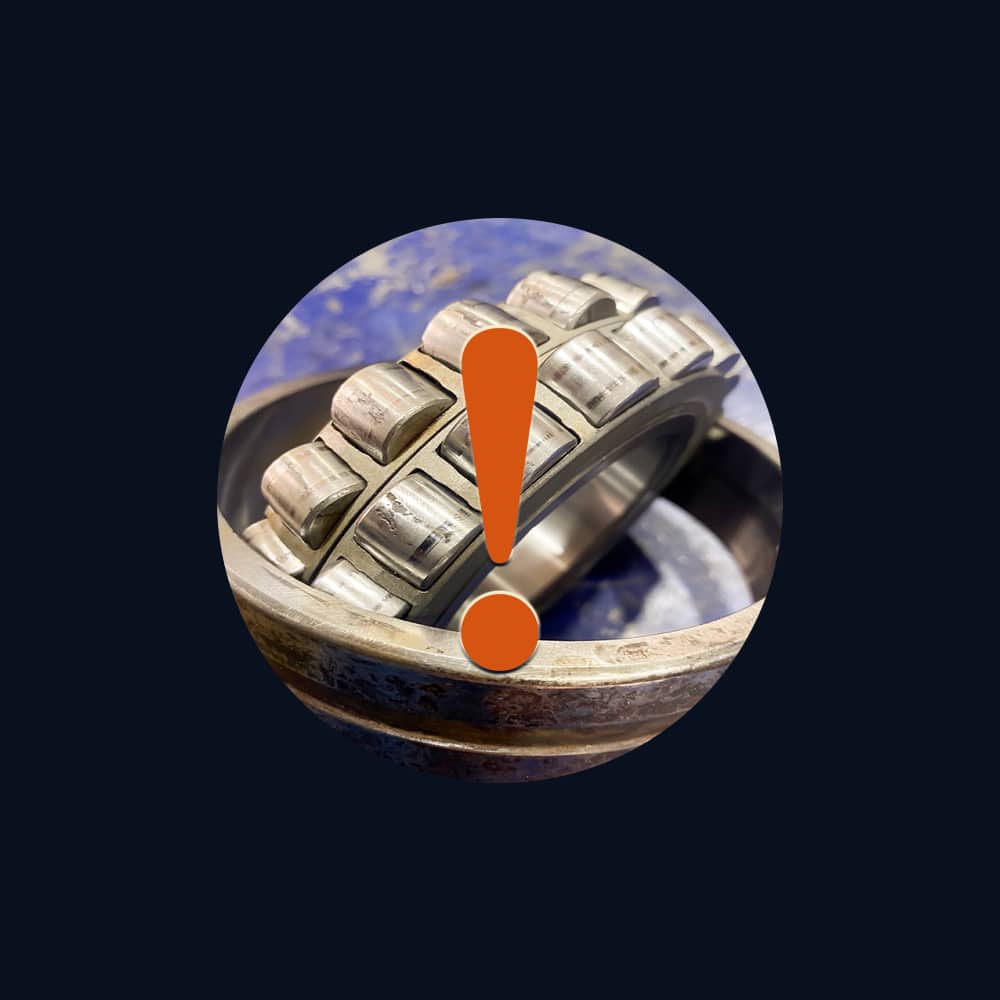

Common Failures & Diagnostics

Rapid Triage

1) Skidding / Smearing (insufficient preload)

Symptoms

Irregular noise, cage marks, polished bands on raceways, heat at speed-up.

Likely causes

Preload too low; contact angle mismatch; lubricant too thin at operating temperature.

Checks

Verify preload class, arrangement (DB/DF/DT), thermal growth model, grease bleed/viscosity.

Fix

Increase preload one class or adjust contact angle; choose lubricant with better film at operating speeds; consider micro-textured raceways only after preload is correct.

2) Overheating / Torque Rise (excess preload or drag)

Symptoms

Rapid temperature rise, torque spikes, grease purge, early noise.

Causes

excessive preload; seals with high drag in high-speed service; incompatible grease.

Fix

reduce preload class; use lower-drag seals or open configuration; choose low-bleed grease or oil system.

3) Fretting / False Brinelling (vibration at rest)

Symptoms

pitch-spaced dents, reddish/black oxides, start-up roughness.

Fix

secure fits, transportation locks, vibration isolation, grease with good film persistence; micro-textured hard chrome may reduce adhesive onset.

4) Corrosion / Chemical Attack

Symptoms

Staining near seals, rough running post-wash/chem exposure.

Fix

improve sealing and wash practices; use compatible grease; apply corrosion-resistant surfaces if ingress cannot be fully avoided.

5) Abrasive Wear / Contamination

Symptoms

Gritty sound, rising torque, debris in grease.

Fixes

upgrade sealing (2RS/labyrinth + slingers), filtration, purge intervals; hard, low-roughness surfaces as complement.

The Big Three: Corrosion; Lubricity; Dimensional Stability

Apply coatings when they address a surface‑driven failure mechanism (corrosion, fretting, abrasion). Do not apply coatings as a substitute for proper fits, clearance, sealing, or alignment.

Network of microcracks acting as corrosion barriers with proper post‑treatChemical resistance, biocompatibility optionsCrack network requires precise process control; clearancesHarsh cleaners, medical/bioprocessPoor sealing environment

| Concern | What it means | Non-coating controls (first) | When coatings help | Notes |

| Corrosion resistance | Resist rust/chemical attack in target environment | Sealing strategy, jet angle, drying, compatible grease | Thin dense chrome (nodular), microcracked chrome | Validate food/biocompatibility if applicable; check pH |

| Lubricity | Low friction, film retention, anti-skid under preload | Correct preload, angle, lubricant; avoid under-preload | Micro-textured hard chrome can reduce fretting/false brinelling and aid film persistence | Coatings complement but don’t replace preload discipline |

| Dimensional stability | Preserve geometry/fit/preload and seal gaps | Check fits/shoulders; thermal model; preload shift with heat | Use controlled-thickness coatings; verify post-coat runout & preload | Thin/mini geometries are sensitivity hot-spots |

Fits, Preload & Contact Angle (Quick Rules)

Pairing:

- DB (\u2190\u2192): highest moment stiffness; best for bidirectional thrust in precision assemblies.

- DF (\u2192\u2190): better for slight misalignment; somewhat lower stiffness vs. DB.

- DT (\u2192\u2192): tandem for higher thrust in one direction; use mirrored DT sets for both directions.

Preload classes: light → medium → heavy; higher preload raises stiffness but heat/torque; confirm thermal growth to avoid excessive preload at operating temperature.

Contact angle: lower (≈15°) for speed; higher (≈25°–40°) for axial capacity; match to duty cycle.

Fits: inner ring typically light interference (e.g., k5–m6) on rotating shaft; housing H6–H7 depending on alignment strategy; avoid creep that pumps lubricant/fluids.

Markings: use matched and marked duplex sets from OEM; don’t “homebrew” preload by random pairing.

Frequently Asked Questions

DB for stiffness and bidirectional thrust; DF for slight misalignment tolerance; DT for one-direction thrust (use mirrored DT for both).

For precision or controlled preload, yes—use OEM duplex sets with defined preload.

Coating thickness can alter geometry slightly; verify preload and seal gaps post-process.

Have a failure photo, sound clip, or spec?

Upload it for a no‑fluff diagnostic checklist. We’ll map symptoms → checks → next actions (and only propose coatings when they’re truly indicated).