| What you’re seeing (symptoms) |

Likely failure mode |

Armoloy-available treatments |

Other industry options (not offered by Armoloy) |

Benefit focus |

|

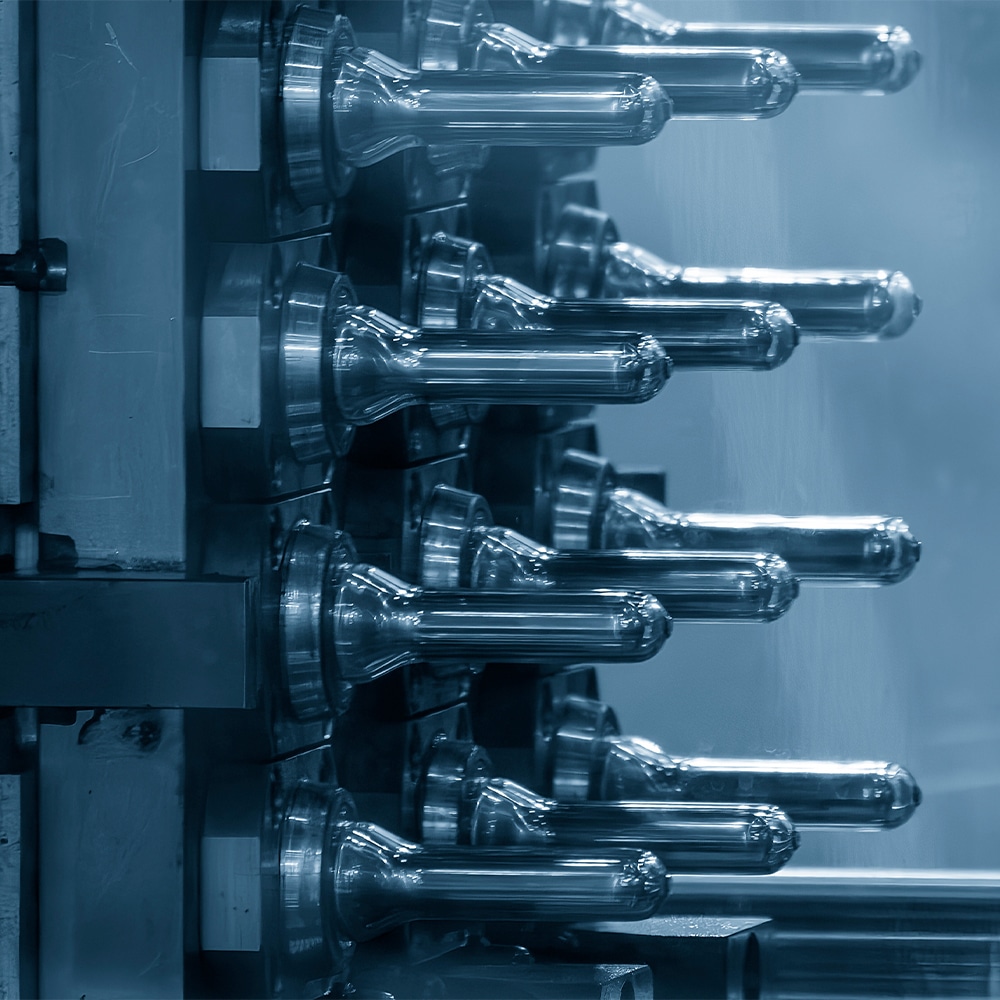

Scuffing on neck rings, thread splits, wear marks on sliding zones; parts show surface scuffs tied to tooling contact

|

Adhesive wear (galling) + sliding wear under load; friction-driven damage on contact interfaces

|

Thin Dense Chrome (TDC)

Thin, uniform hard surface to help mitigate wear and preserve critical geometry where tight tolerances matter.

Surface engineering consult

We’ll validate whether hardness, friction behavior, and dimensional build are aligned to the specific sliding interface.

|

DLC (PVD/PACVD) (typical 1–5 µm)

CrN (PVD) (typical 2–4 µm)

Often selected for low friction and anti-galling behavior; supplied by PVD providers.

|

Metal + performance

Less galling/scuff, steadier quality

|

|

Sticking on core rods/blow pins; material pickup; higher ejection force; occasional corrosion marks depending on resin/additives

|

Friction + adhesion (buildup) and/or corrosion-driven surface roughness that increases “grip”

|

High-Phos Electroless Nickel (ENP) (where specified)

Uniform barrier coverage where corrosion resistance and thickness control are priorities.

Electroless Nickel + PTFE (EN-PTFE) (where specified)

Helps reduce adhesion and friction that can drive sticking and cleanup frequency.

|

DLC topcoat on select zones

Sometimes used as a low-friction top layer; supplied by other providers.

|

Performance failures

Sticking, downtime, scrap reduction

|

|

Edge wear on critical features; loss of sharp definition leading to inconsistent neck finish, sealing issues, or cosmetic defects

|

Abrasive wear and geometry loss on sharp or high-contact features

|

Thin Dense Chrome (TDC)

Thin, uniform hard chromium to preserve sharp geometry with minimal dimensional growth.

|

CrN (PVD) and other hard PVD films

Often used when an external provider is selected for thin-film wear protection.

|

Metal failures

Wear mitigation / geometry retention

|

|

Hot spots, seam/parting integrity issues, temperature-driven dimensional instability near neck/parting features

|

Thermal management limitation (heat extraction and stability) more than a pure “coating problem”

|

Surface engineering consult

We help confirm whether a surface treatment is compatible with thermal goals and which areas should remain untreated for heat transfer.

|

High-conductivity copper alloys (e.g., MoldMAX HH; AMPCOLOY 944)

Common substrate/insert option to improve heat extraction in hot zones (material selection).

|

Performance failures

Quality stability / seam integrity

|

|

Corrosion risk, staining, haze after cleaning/washdown; surfaces that trap buildup or contaminate product

|

Corrosion initiation + surface roughness/buildup sites

|

Electropolish + passivation (where applicable)

Surface smoothing and corrosion-resistance restoration on suitable alloys to reduce buildup sites and improve cleanliness.

|

ASTM A967 passivation (industry standard process)

Commonly specified for stainless corrosion performance improvements (performed by qualified providers).

|

Metal + performance

Corrosion control & cleanliness

|

|

Concern about high-strength steels after electroplating; cracking risk under load after plating

|

Hydrogen embrittlement susceptibility (process risk that must be managed)

|

Relief bake (post-plate) (when required by material/process)

Used to reduce embrittlement risk on susceptible high-strength steels following electroplating.

|

ASTM B850 guidance (industry standard)

Common reference for post-plating embrittlement relief practices.

|

Metal failures

Risk mitigation

|