summary

What is Intracutaneous Irritation?

What is an Intracutaneous Irritation Test?

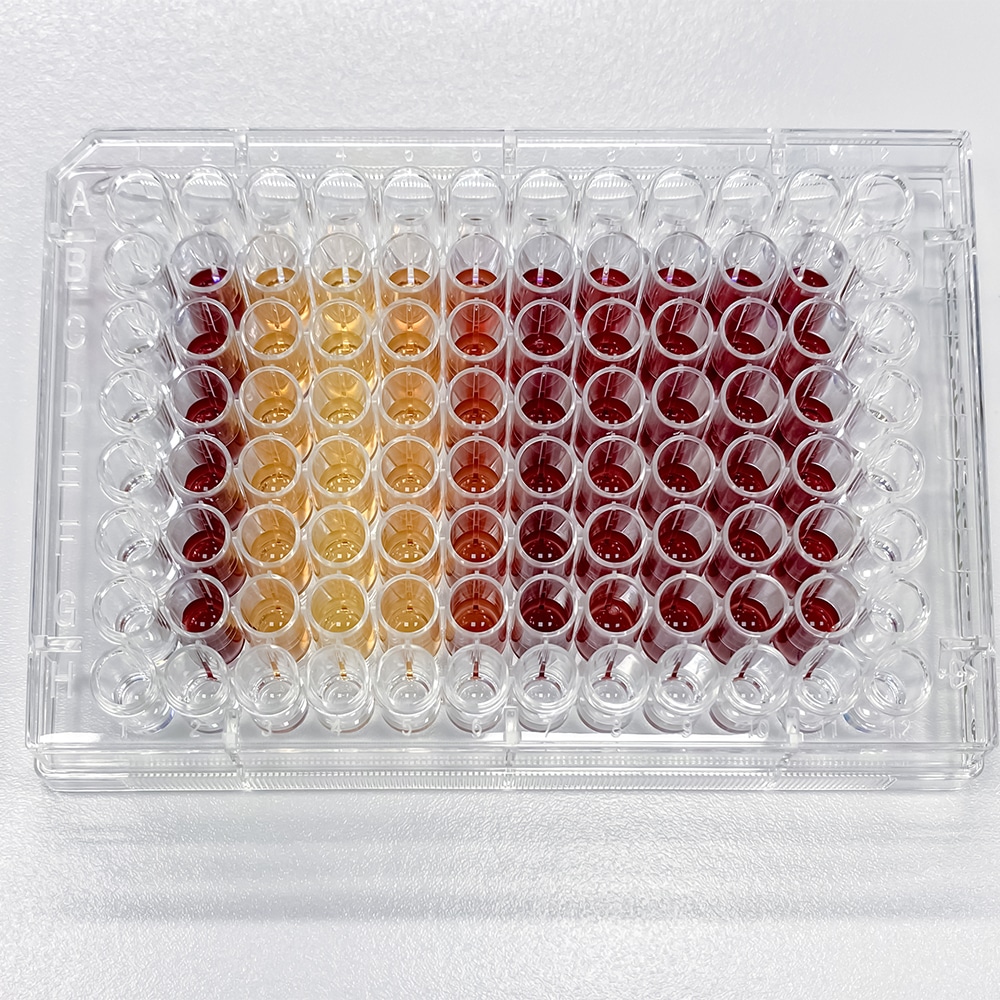

This test involves injecting both test extracts and control substances into rabbits and observing the skin’s reaction at the injection sites. For this study:

- ME-92 was extracted using saline (0.9% NaCl) and sesame oil, following ISO 10993-10 extraction guidelines.

- Extracts were injected into five sites on the right side of each rabbit.

- Corresponding control vehicles (saline or sesame oil) were injected on the left side.

- Sites were observed at 24, 48, and 72 hours for signs of erythema and edema.

A difference in mean irritation score of 1.0 or less between test and control groups is considered non-irritant.

ME-92 Intracutaneous Test Summary

ME-92’s coating was applied to 304 stainless steel (Lot #38408) and tested at NAMSA, an ISO-accredited lab. The key findings:

- Saline Extract Irritation Score (Test – Control): 0.0

- Sesame Oil Extract Irritation Score (Test – Control): 0.0

- Erythema/Edema Observed: None beyond slight, isolated redness (Grade 1), consistent with normal injection response

- Conclusion: ME-92 coating caused no irritation in this vivo model

All animals remained healthy, and controls behaved as expected, validating the study.

Why Intracutaneous Testing Matters

Biocompatibility is not just about what a coating does—it’s about what it doesn’t do. ME-92 showed no signs of irritation in tissue-contact testing, reinforcing its safety for use in implants, surgical devices, and blood-contact medical tools. Low irritation scores help prevent post-op complications and ensure faster healing.

Partner With Us

Trust what’s under the surface. Partner with ME-92 for medical coatings that meet ISO standards for irritation, safety, and performance.