armoloy specifications

What is MIL-C-26074?

The Role of MIL-C-26074 in Electroless Nickel Plating

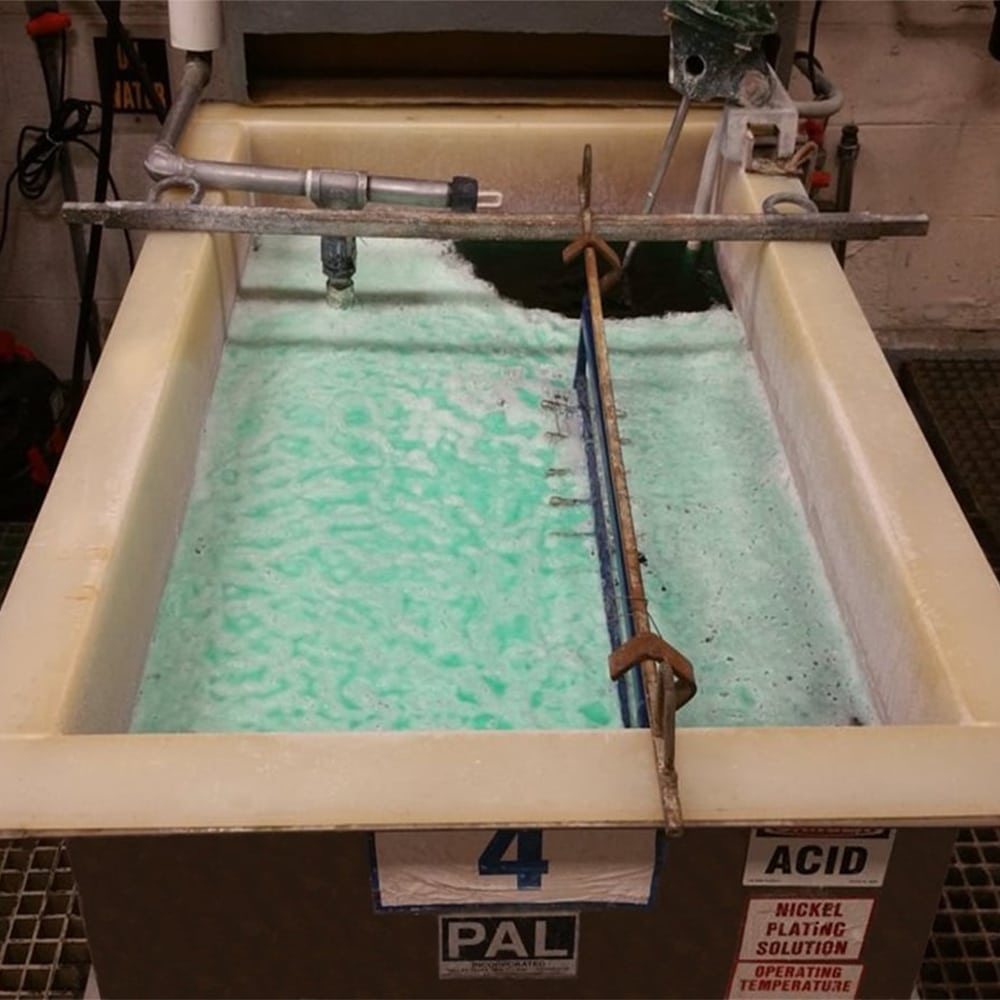

MIL-C-26074 (or AMS-C-26074) ensures electroless nickel coatings meet rigorous military and industrial standards. This specification plays a vital role in delivering:

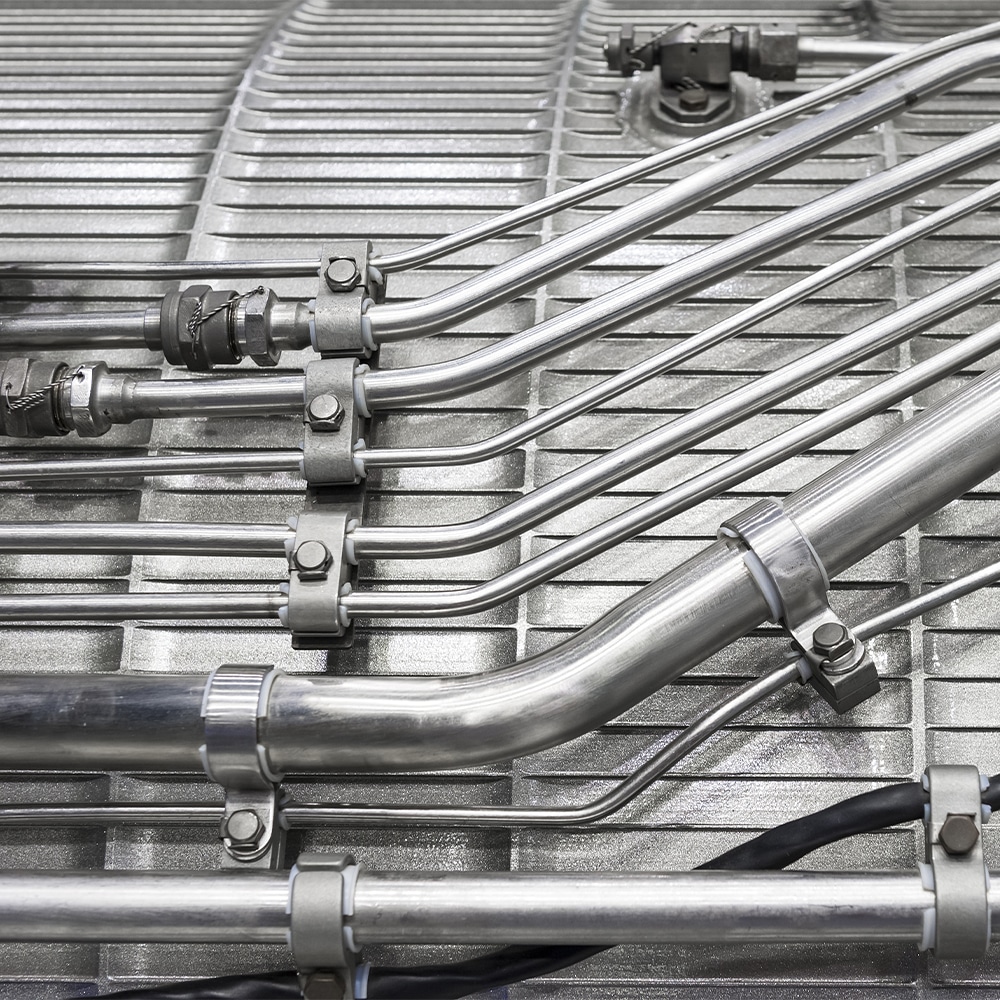

- Uniform Coating: Ensures even plating across complex surfaces.

- Variable Thickness Options: Supports coatings tailored to specific performance needs, from minimal protection to heavy-duty use.

- Versatile Finishes: Offers options for different finishes to meet functional and aesthetic requirements.

- Metal and Non-Metal Application: Allows plating on conductive and non-conductive surfaces, broadening its use across diverse materials.

MIL-C-26074 remains a widely used standard for applications that rely on electroless nickel plating to enhance performance, extend component life, and meet operational requirements.

MIL-C-26074 Testing Methodology and Results

MIL-C-26074 defines strict testing methods to verify the strength, adhesion, and corrosion resistance of electroless nickel coatings. Key tests include:

- Thickness Measurement: Techniques like cross-sectional analysis, magnetic methods, and X-ray spectrometry verify uniform plating thickness.

- Hydrogen Embrittlement Relief: Heat treatment is applied to hardened steel components to reduce brittleness after plating.

- Corrosion Resistance: Salt spray testing confirms the coating’s ability to withstand corrosive environments.

- Adhesion Testing: Bend, impact, and pull-off tests verify that the coating remains bonded under mechanical stress.

With clearly defined methods, MIL-C-26074 brings clarity and consistency to plating processes across a wide range of materials and applications.

Applications For MIL-C-26074 Electroless Nickel Plating

MIL-C-26074 is widely used in aerospace, military, and defense applications, including:

- Aircraft Components: Protects landing gear, engine parts, and other critical systems with corrosion-resistant coatings.

- Missile Systems: Enhances wear and corrosion resistance for guidance systems and structural parts.

- Naval Vessels: Coats propulsion systems, hull fittings, and submarine components for exceptional performance in harsh marine environments.

- Military Vehicles: Safeguards tanks and armored personnel carriers from corrosion and mechanical wear.

- Defense Electronics: Ensures reliability and environmental resistance for connectors and other electronic components.

- Weapon Systems: Extends the durability of firearms and critical weapon components.

MIL-C-26074 is vital in preserving military equipment, reducing maintenance, and ensuring operational readiness.

Benefits of Working with a MIL-C-26074 Provider

Precision coating application

Providers follow strict guidelines to deliver uniform electroless nickel coatings tailored to your needs

Consistent corrosion protection

Coatings protect components from harsh conditions, extending their service life

Military-grade compliance

Providers meet strict military specifications, ensuring components are suitable for mission-critical applications

Reliable quality assurance

Standardized processes deliver consistent, dependable performance across all plated components

Consistent wear resistance

Specialized coatings reduce friction and extend the life of high-stress parts

Expert solutions

Experienced teams handle complex designs and unique materials

Risk reduction

Thorough testing and adherence to standards minimize the risk of failures or costly rework

Full traceability

Providers offer comprehensive documentation that supports audits and quality assurance

Specifications at Armoloy

Armoloy offers plating solutions that meet MIL-C-26074 to support both regulatory compliance and individual project needs. Explore common specifications and accreditations we work with, and contact us to find the right solution for your application.

Disclaimer

The information provided on this page, including any descriptions, interpretations, or summaries related to MIL-C-26074 and AMS-C-26074, is offered solely by The Armoloy Corporation for general informational purposes. This content reflects Armoloy’s internal understanding and practical application of these specifications within its own processes and does not constitute official or authorized guidance from SAE International.

MIL-C-26074 and AMS-C-26074 are proprietary standards developed and owned by SAE International. Armoloy makes no claim to ownership of these specifications and does not reproduce, quote, or distribute any protected content from the original documents. References to MIL-C-26074 and AMS-C-26074 are made in accordance with fair use principles and are intended to illustrate Armoloy’s alignment with widely recognized electroless nickel plating standards.

This content is not intended to substitute for the official specifications, which should be obtained directly from SAE International. Readers are strongly encouraged to consult the original standards and qualified professionals for definitive technical or compliance information.

The Armoloy Corporation makes no warranties, express or implied, regarding the accuracy, completeness, or applicability of this content and disclaims all liability for any reliance placed upon it. This disclaimer is subject to change without notice and does not create any contractual relationship or obligation.