Electrolytic Nickel Plating

Advantages of Electrolytic Nickel Plating

Electrolytic vs. Electroless Nickel

The electrolytic and electroless nickel plating methods both serve to deposit nickel on substrates but differ fundamentally in their processes and applications. Electrolytic nickel plating requires an external electrical current to drive the deposition of nickel from an electrolyte solution onto the substrate, making it highly controllable and suitable for achieving varied thicknesses and surface characteristics. This method allows for detailed control over the aesthetics of the finish, offering options from bright to matte.

In contrast, electroless nickel plating does not use an electrical current but instead relies on a chemical reaction to deposit nickel, leading to very uniform thickness even on complex shapes. This makes it ideal for applications requiring consistent coverage over intricate surfaces and excellent corrosion resistance. Electroless plating is typically more expensive due to the chemicals used and is less customizable in terms of finish aesthetics.

Electroless nickel is also an alloy of nickel and phosphorus. While excellent for corrosion resistance, it has poor conductivity. Therefore, if improved conductivity is a requirement, electrolytic nickel should be chosen over electroless nickel plating.

Performance Characteristics

Electrolytic Nickel by the Numbers

- Heat resistant up to 1,832°F (1000°C)

- Deposit range of 0.0002″ – 0.003″

- Ductility high enough to meet or exceed AMS 2424

- Average microhardness below 300HV

Electrolytic Nickel Highlights

- Pure nickel deposit

- Enhanced conductivity

- High temperature tolerance

- Bright appearance

- Applicable to nearly all base metals

- Non-magnetic

Proven applications

Electrolytic nickel plating has improved the long-term performance of a myriad of components – some include:

- Automotive

- Turbine blades

- Landing gear

- Decorative items

- Bathroom fixtures

- Electronics

- Heavy machinery

- Defense applications

Test Methods used to Certify Coatings

- AMS 2424

- AMS 2403

- ASTM B689

- ISO 1458

Electrolytic Nickel Features & Benefits

Base metal compatibility

Adheres to nearly all ferrous and non-ferrous materials, and provides a low-temperature plating process (<190°F, <88°C)

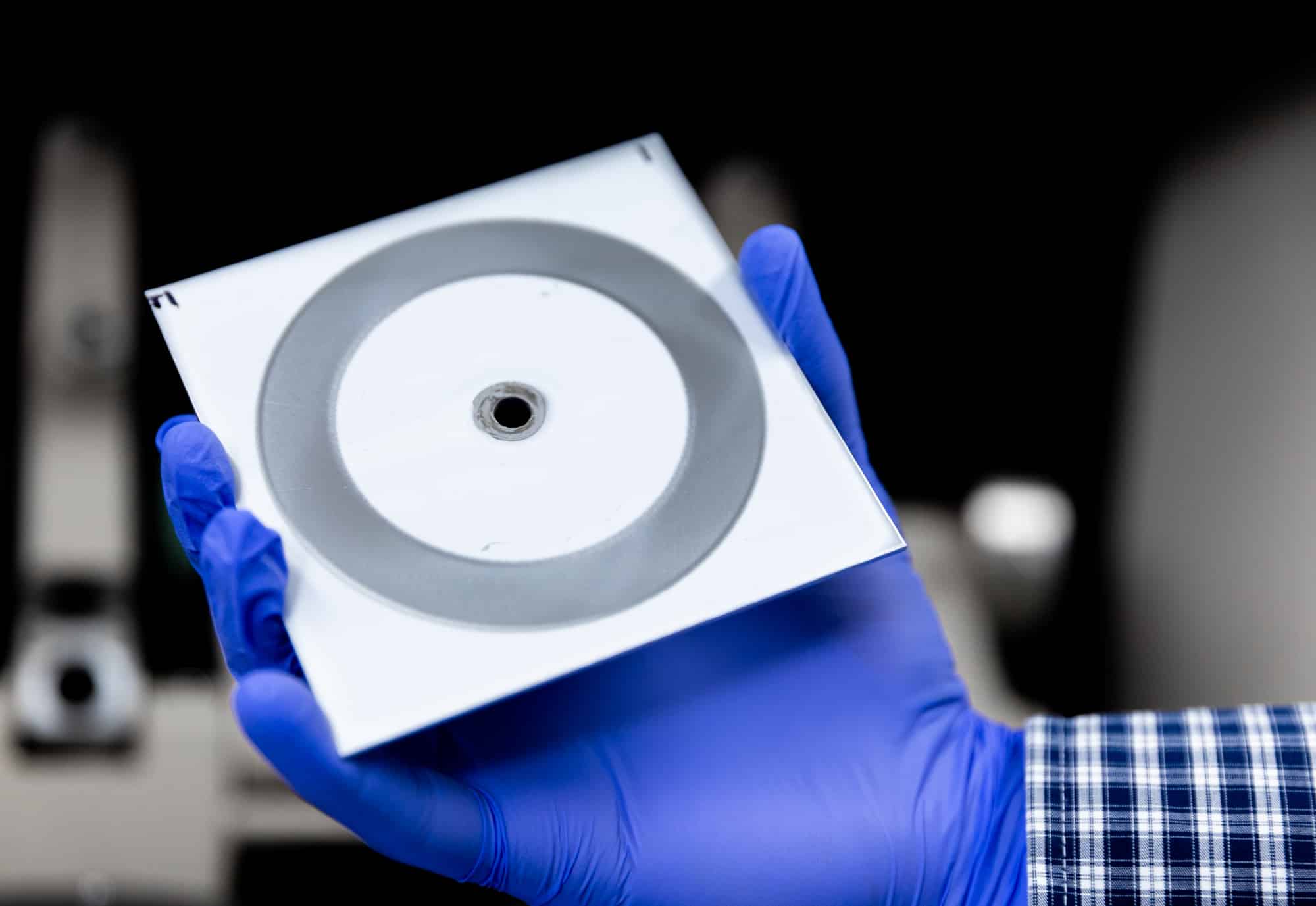

Pleasing aesthetics

Offers a shiny, appealing finish that enhances the visual quality of the product

Corrosion resistance

Protects the base material from oxidizing and corroding, essential for parts exposed to harsh environments

Increased conductivity

Improves the conductivity of the surface, beneficial for electronic components

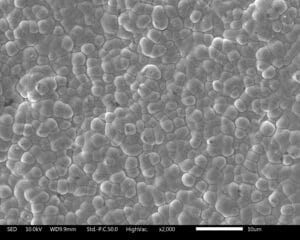

Uniform thickness

Allows for precise control over the deposition process, which can achieve uniform thickness across the coated part

High heat tolerance

Withstands post-plate firing temperatures of 1,000°C (1,832°F)

Cost effectiveness

Generally more cost-effective than electroless plating for large production volumes due to faster plating times and less chemical usage

Improved brazeability

Electrolytic nickel is used on some alloys to improve wettability during the brazing process creating stronger, more durable joints

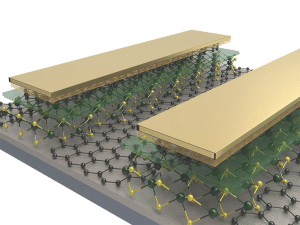

The Science Behind Electrolytic Nickel

The electrolytic nickel plating process involves several key steps. Initially, the parts to be plated are thoroughly cleaned to remove any contaminants that could interfere with the adhesion of the nickel. The substrate is then immersed in an electrolytic bath containing nickel salts. The part acts as the cathode (negative electrode), and anodes (positive electrodes) made of nickel dissolve into the bath, replenishing the nickel ions.

When an electrical current is passed through the bath, nickel ions gain electrons (are reduced) and deposit onto the cathode surface. The thickness and properties of the nickel layer can be precisely controlled by adjusting the voltage and current, the composition of the electrolyte, the temperature, and the plating time. This control is essential for achieving the desired characteristics and quality of the coating.

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Need a bright, durable finish? Let’s coat with electrolytic nickel.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.