Some of the most common food-safe coatings include:

- Electroless Nickel (EN): Known for its corrosion resistance and durability, electroless nickel is often used on food processing equipment.

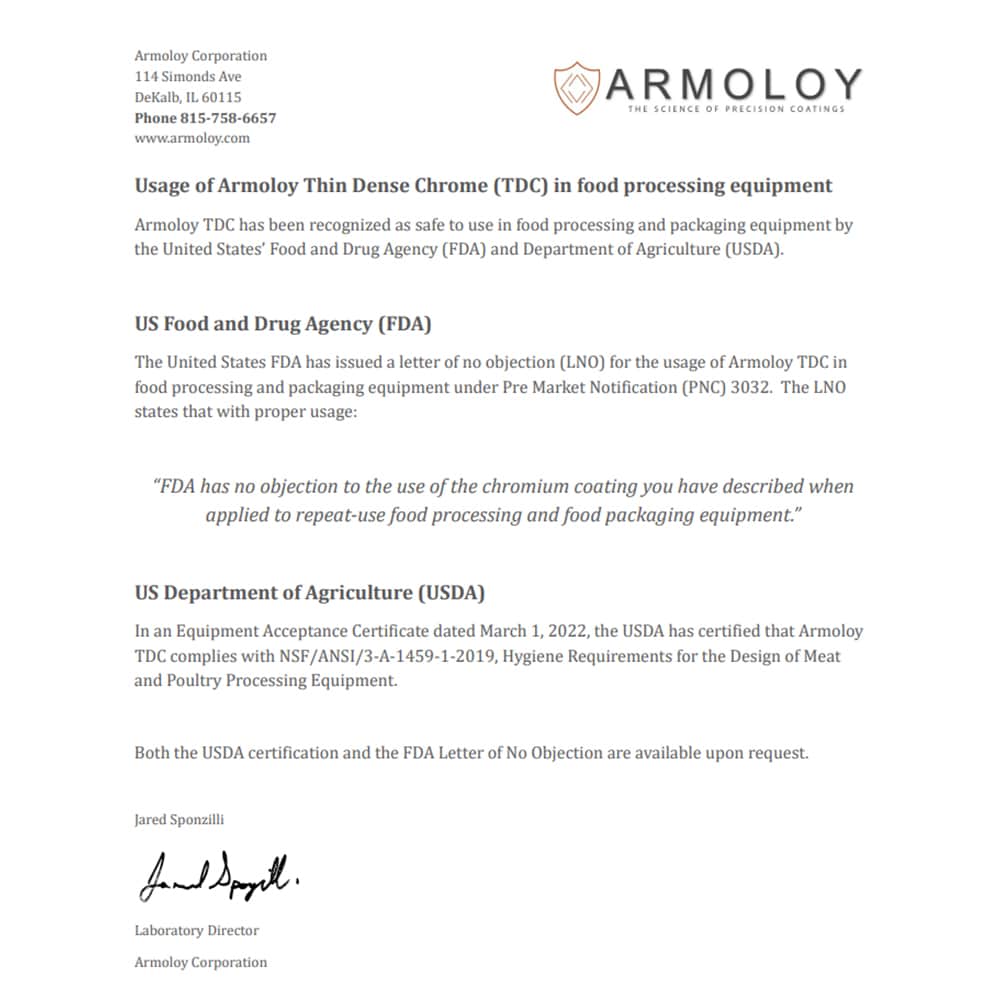

- Thin Dense Chrome (TDC): Armoloy Thin Dense Chrome is a food-safe coating that provides excellent wear resistance, reduces friction, and prevents corrosion.

- PTFE (Polytetrafluoroethylene): Commonly known as Teflon, this non-stick coating is used in cookware and food packaging machinery.

- Ceramic Coatings: Ceramic coatings are highly durable and resist high temperatures, making them ideal for food contact surfaces.

When choosing food-safe coatings, ensure they are certified and meet your specific component requirements to maintain safety and compliance.