Armoloy Nodular Thin Dense Chrome (NTDC) is a specialized metal surface treatment designed to improve hardness as well as aid in corrosion prevention. The Armoloy process involves applying a thin layer of chromium to a metal surface, achieving deep penetration without significantly increasing the metal’s thickness. Certified by the USDA for use in food-related applications, this NTDC treatment increases a metal’s hardness to approximately 78 Rockwell C (Rc). Its proprietary deposition method ensures the coating doesn’t crack, flake, or peel from any substrate its adhered to. Additionally, the low-temperature application process helps in minimizing metal distortion, and eliminates galling. The treatment is reversible and can be stripped and reapplied without impacting the underlying metal.

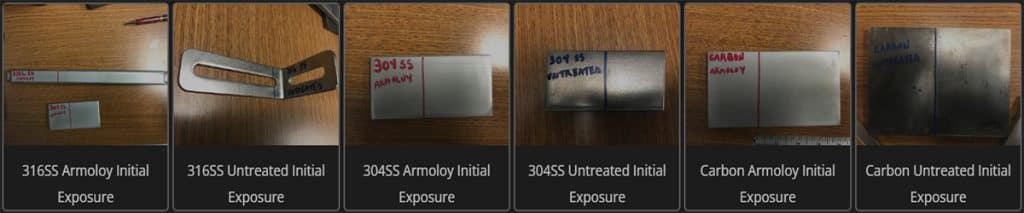

In a comparative case study, six metal samples were analyzed – three treated with Armoloy Nodular Thin Dense Chrome and three left untreated. The samples included 304L SS, 316L SS, and carbon steel. Each sample was exposed to a brine solution once weekly over a four-week period, with detailed observations and photographs taken.

The aim of this case study was to evaluate the effectiveness of the Armoloy NTDC treatment in preventing corrosion, particularly for components exposed to brine in industrial settings such as food processing and packaging.

STUDY TIMELINE

Day 1: All samples were initially exposed to the brine solution.

Day 7: Treated samples exhibited negligible corrosion. The carbon-treated sample showed a change in color possibly due to metallic dust, but no metal degradation. 316 and 304 treated samples remained corrosion-free. Oxidation was present in all treated samples, with the carbon sample showing surface corrosion and metal wear. The 304 treated sample had surface oxidation and slight metal corrosion, while the 316 sample only displayed surface oxidation.

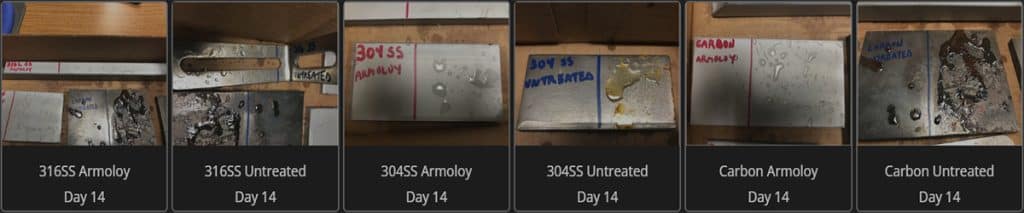

Day 14: Treated 316SS and 304SS samples remained corrosion-free with minor surface oxidation. The carbon-treated sample showed minimal corrosion and surface pitting.

Day 21: Stainless steel treated samples continued to show no signs of corrosion, with the carbon sample exhibiting slight surface oxidation. The Armoloy-treated samples displayed ongoing corrosion, more pronounced in the 304 SS sample. The 316SS sample primarily showed surface oxidation.

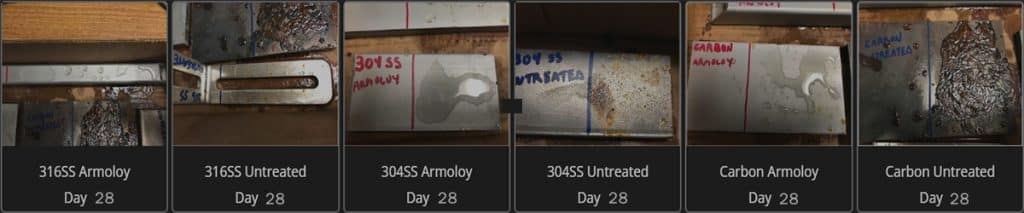

Day 28: Treated samples maintained their resistance to brine corrosion, with the carbon sample showing only minor surface oxidation. The Armoloy-treated samples exhibited continued corrosion progression.

CONCLUSION

Upon completion of the 28-day study, Armoloy Nodular Thin Dense Chrome coating shows significantly enhanced corrosion prevention of metal components exposed to brine solutions.