Nickel Chrome Hybrid Plating

Balanced Protection for Increased Performance

Best Combination of Wear & Corrosion Protection

The Armoloy Corporation helps manufacturers safeguard their high-precision metal components with a premium lineup of precision coatings.

Armoloy’s team of engineers conduct rigorous evaluations to determine the most appropriate texture and co-deposit for each application. This technical approach ensures that metal components are not only safeguarded from potential failures but also optimized for operational performance and longevity. The introduction of Bi-Protec® as a hybrid solution marks a significant step forward in the realm of metal component coatings, providing a technically advanced solution for corrosion and wear resistance challenges.

Armoloy Bi-Protec A Highlights

- Thin dense chrome with high phosphorus electroless nickel

- Balanced combination of wear and corrosion resistance

- Effectively bonds to aluminum components

- Broad effective temperature range

- Complete coverage over complex geometries

- Silver satin appearance

- Enhanced release properties

- Prevents galling and fretting

Armoloy Bi-Protec X Highlights

- Diamond chrome with high phosphorus electroless nickel

- Optimal combination of wear and corrosion protection

- High hardness for the most abrasive applications

- Effectively adheres to aluminum substrates

- Resists galvanic activity

- Rivals 440C stainless steel with the ability to withstand oxidation

- Thermally conductive

- Broad effective temperature range

- Prevents galling and fretting

- Improves lubricity

Proven applications

Applying Bi-Protec® can improve the long-term performance of all the following industry-specific applications.

Performance Characteristics

Bi-Protec by the Numbers

- Electroless nickel thickness of .0002/.003′′ (5.08/76.2 µm)

- .0001/.0005′′ (2.54/12.7 µm) deposit of thin dense chromium

- Surface hardness up to 78Rc

- Corrosion resistance tested per ASTM B-117

- .0035″ (88.9 µm) max deposit

- < 190°F (<88°C) processing temperature

- 800°F (427°C) max working temperature

- Wear resistance less than 1.2 TWI

Bi-Protec Features & Benefits

Nickel-chromium hybrid

Combines extreme corrosion resistance of nickel and proven wear advantages of Armoloy TDC

Heavier deposits available

Corrects undersized tools

Double-layered protection

Beneficial for extreme corrosive/wear operating environments

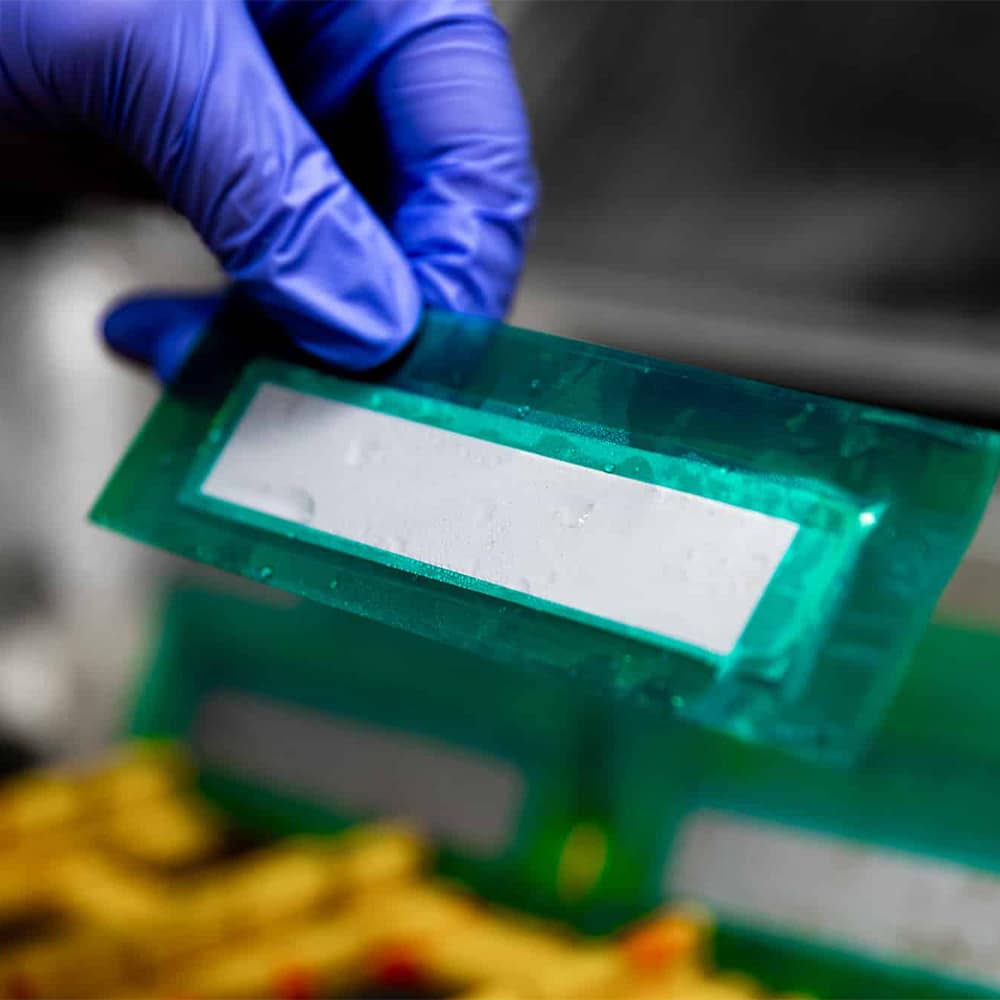

Plating on aluminum

Ability to apply NTDC to aluminum by first coating with a thin layer of nickel

Low processing temperature

Will not distort base material. Eliminates annealing

Chemical resistance

Stable in alkalis, solvents, acids and gasses

Wide range of materials

Compatible with nearly all base metals

Lasting aesthetic appeal

Gives components a matte finish that won’t easily fade over time

Great adhesion

Will not flake, crack, or separate from the base material

Lubrication retention

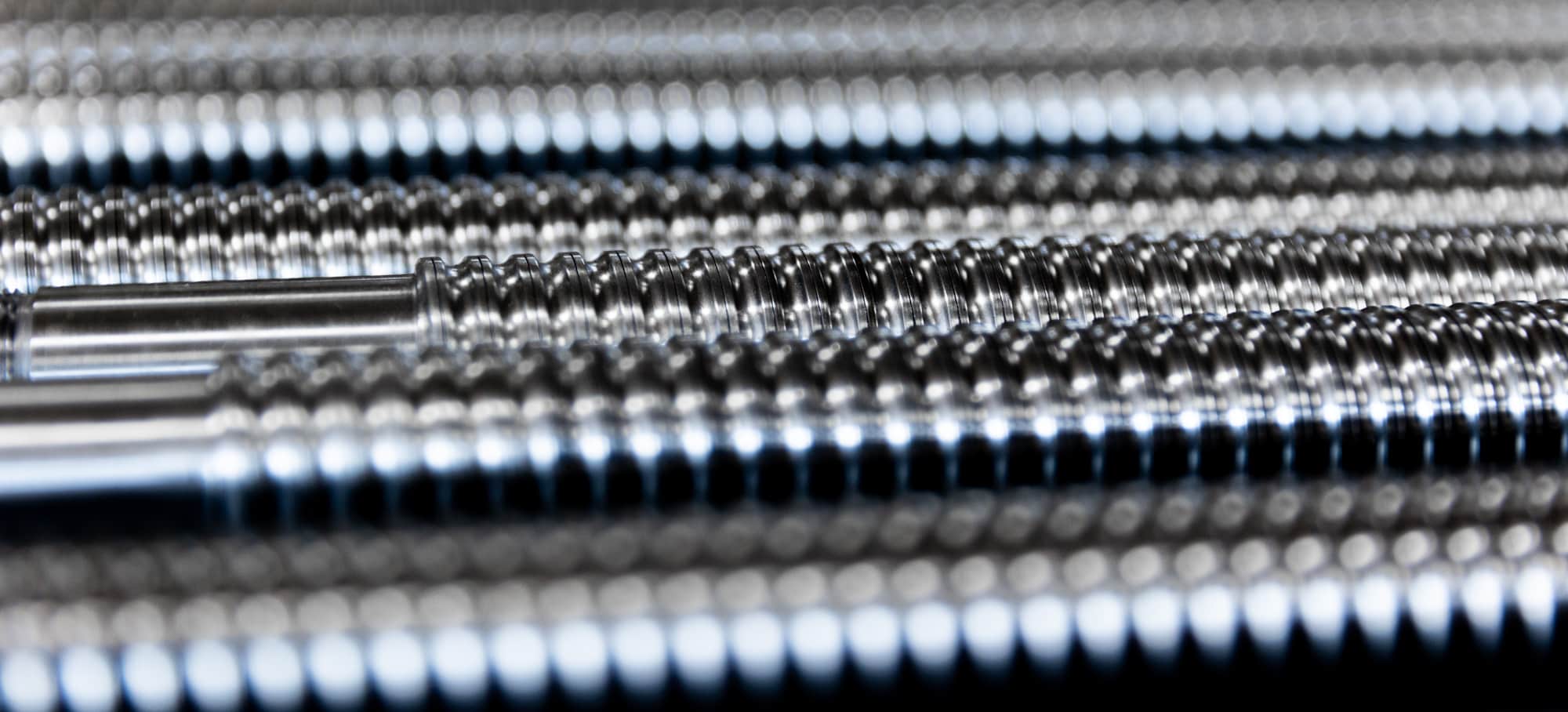

Nodular surface retains wet and dry lubricants

Galling protection

Good resistance to adhesive wear, enhanced tolerance of low-lube

No sharp edge buildup

Minimizes dimensional changes to base material

The Science Behind Bi-Protec

How it Works

The process of creating Bi-Protec starts by adding an initial layer of electroless nickel coating directly to the base metal at a thickness of .0002/.003″ (5.08/76.2µm) Once applied we then begin the plating process that adds an overlay of chromium coating —either our nodular TDC or XADC—at a deposit of 0001/.0005″ (2.54/12.7µm).

The overlay of chromium coating you choose will depend on the unique needs of both your metal surfaces and your industry. While both coatings provide enhancements to corrosion and wear resistance, Armoloy XADC proves especially useful for higher-wear applications. This is due to the addition of a synthetic diamond composite that increases hardness and thermal conduction abilities.

Regardless of the coating chosen, Armoloy’s Hybrid Bi-Protec nickel chrome plating provides exceptional benefits for those with highly corrosive applications, including hard-to-plate metals. Capable of providing maximum corrosion protection and increased wear resistance—even in the harshest environments—Bi-Protec can ensure that high-precision applications avoid unplanned downtime.

More on Bi-Protec

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Need dual-layer defense? Let’s talk Nickel-Chrome solutions.

Partner With Us

Improve metal surface performance to its highest pinnacle. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions like our nickel chrome plating.