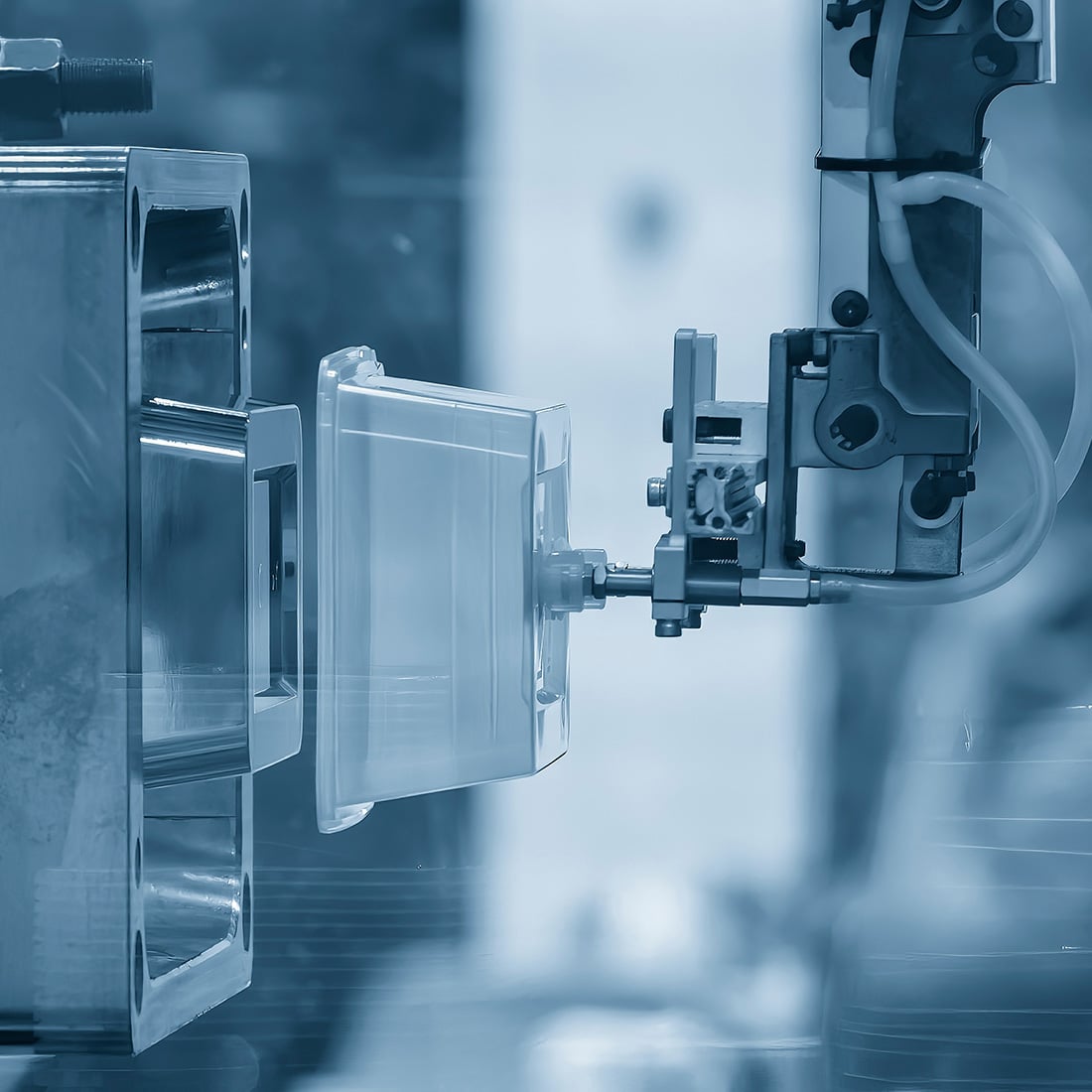

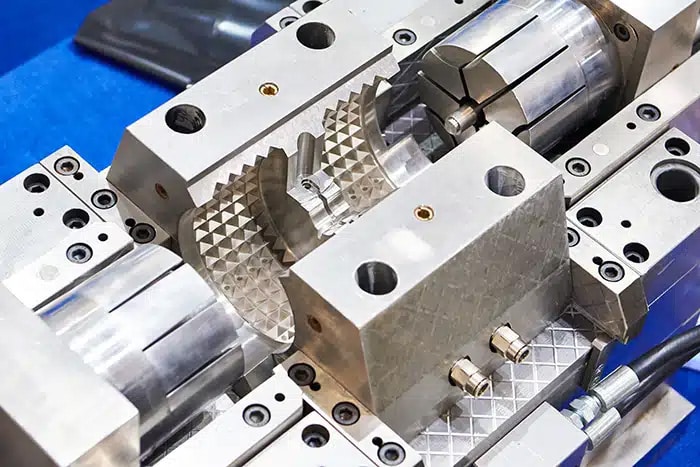

Mold release coatings are essential for preventing materials like plastics, rubber, or composites from sticking to molds during the manufacturing process. These coatings improve the efficiency of mold operations, reduce material buildup, and extend the lifespan of molds. There are several types of mold coatings, each offering unique benefits for specific applications.

- Plating and Coating: Electroplating or chemical processes create a protective metal coating, such as thin dense chrome or electroless nickel, on the mold. These coatings are primarily chosen for corrosion and wear resistance.

- Chemical Vapor Deposition (CVD): CVD coatings, such as silicon carbide or boron nitride, are chemically reactive layers that enhance the mold’s hardness and resistance to wear and heat.

- Physical Vapor Deposition (PVD): PVD forms a thin film on the mold using materials like TiN or TiCN. These coatings increase hardness and protect the mold from wear and abrasion.

- Oxidation Treatment: This method creates an oxide layer on the mold surface to increase corrosion resistance and surface hardness. Common techniques include anodizing and phosphating.

- Thermal Spray: This technique uses a spray gun to apply melted metal or alloy materials, such as ceramics, carbide, or metals. It forms a hard, wear-resistant layer that improves mold durability.

- Polymers: Polymer coatings like polyether or polyurethane are applied to molds to provide excellent wear and corrosion resistance.