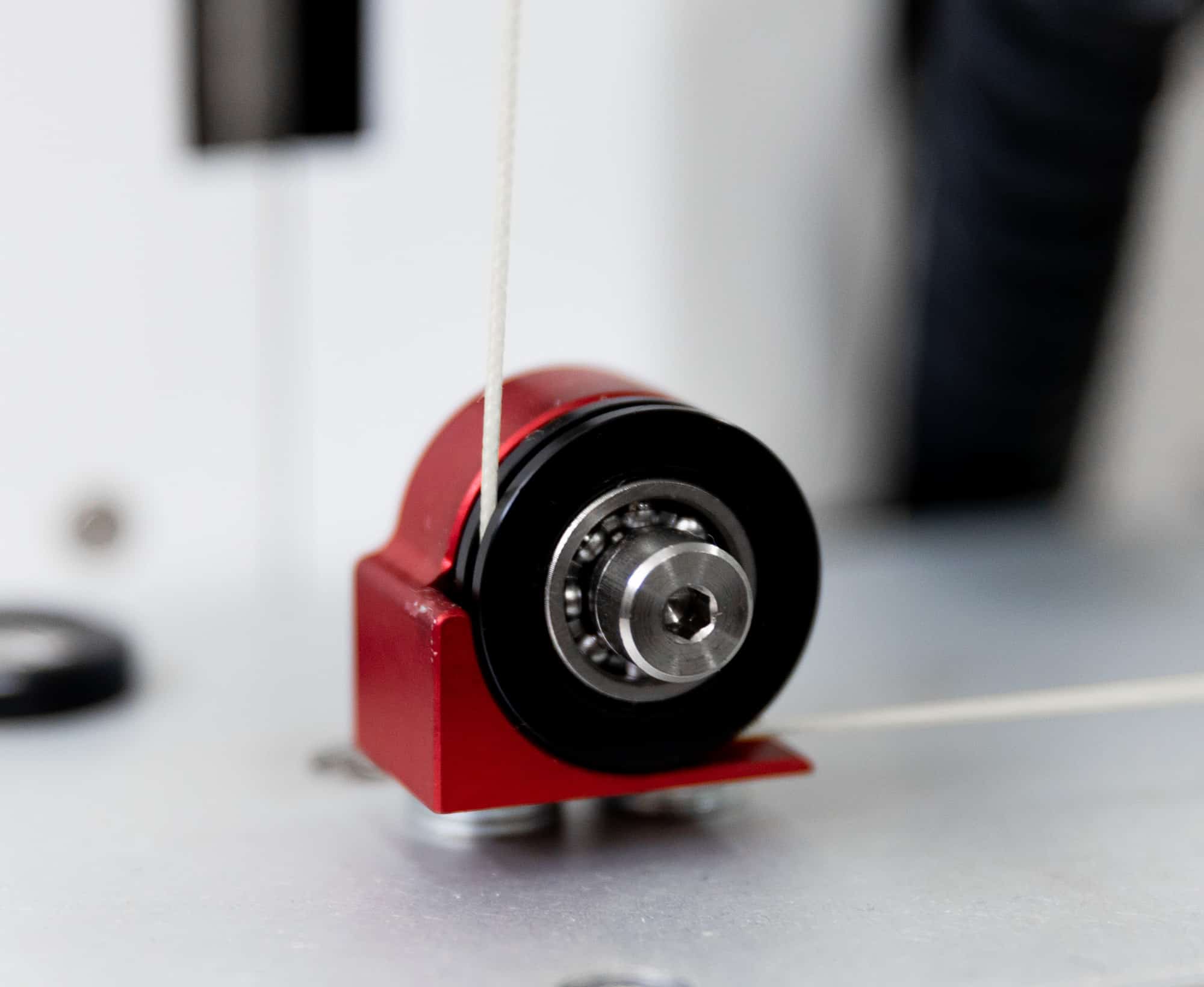

ptfe coatings

Experience the Toughness of Nickel Teflon®

Armoloy’s Precision Composite Coating

The Armoloy Corporation helps manufacturers worldwide protect their most valuable, high-precision applications with a premium lineup of functional coatings.

Our Nyflon® – Nickel Teflon® coating is a distinctive offering in Armoloy’s arsenal, celebrated for its unique blend of nickel’s robustness and Teflon’s low-friction properties. This synergistic combination results in a coating that not only resists wear and corrosion but also minimizes friction and sticking, making it perfect for applications demanding both durability and a non-stick surface. Ideal for a myriad of industrial uses, our Nickel Teflon® coating significantly prolongs component life, enhances operational efficiency, and ensures superior performance under challenging conditions, thereby becoming an essential solution for maintaining the high quality and reliability of precision parts.

Performance Characteristics

Nyflon by the Numbers

- Up to 67% reduction in coefficient of friction

- Corrosion resistance tested per ASTM B-117

- Effective deposits as low as .0002″ – .0006″ (5.08 to 15.24 µm )

- Processing temperature < 200°F (<93°C)

- 400°F (204°C) max working temperature

- Coefficient of thermal expansion 13 x 10-6/°C

- Applicable to nearly all base metals

- Smokey satin appearance

Armoloy Nyflon – Nickel Teflon® Highlights

- Longer lubrication life for hard-to-access parts

- Evenly dispersed nanoparticles of PTFE

- Very low friction coefficient

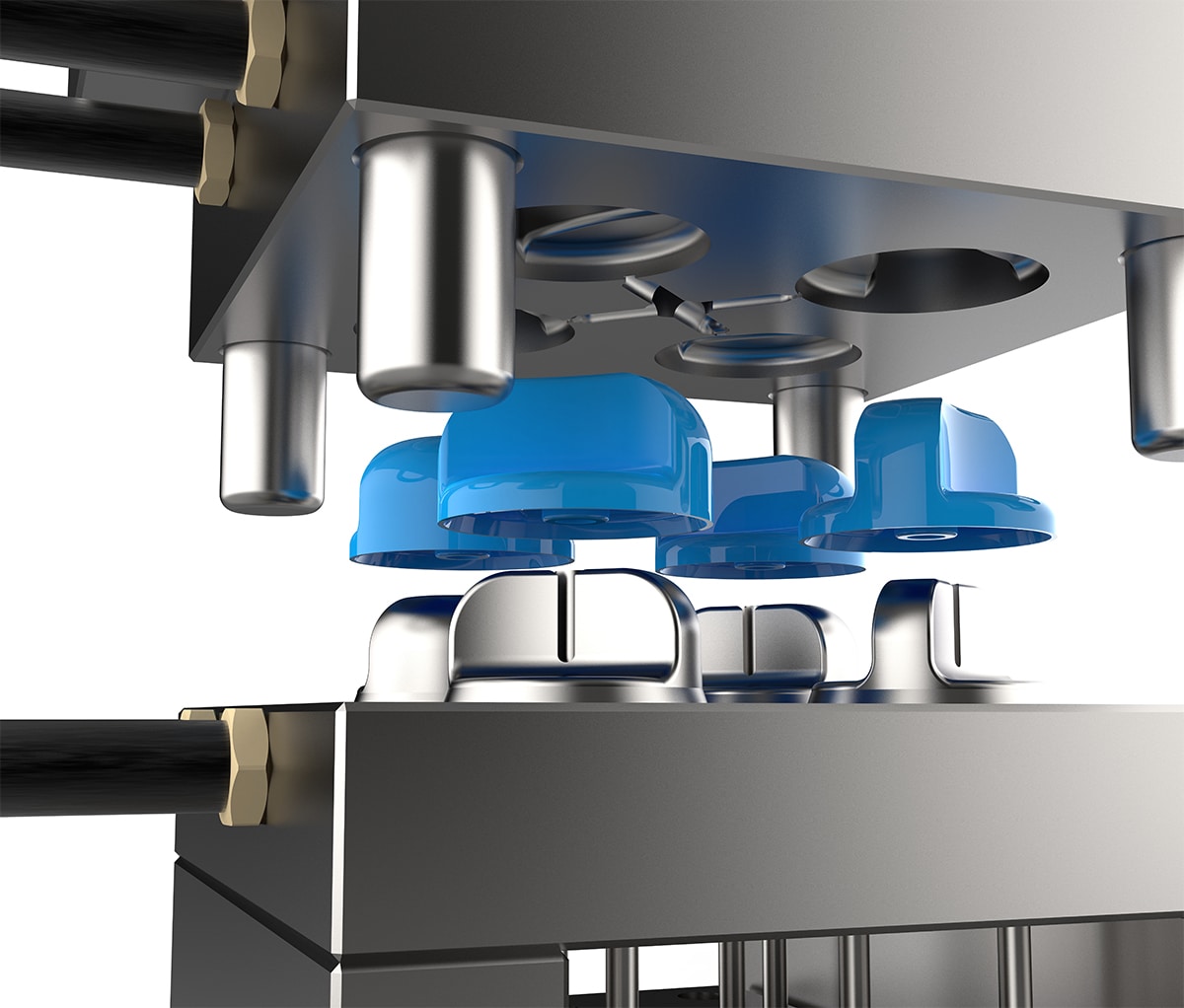

- Optimal release for mold components

- High corrosion resistance

- Hydrophobic, high-phosphorus nickel base layer

- Increased hardness from nickel co-deposit

- Works well in cryogenic temperatures

- Prevents sliding applications from sticking

- Smokey satin appearance

Proven applications

Applying Nyflon industrial Teflon® coating improves the long-term performance of all the following industry-specific applications.

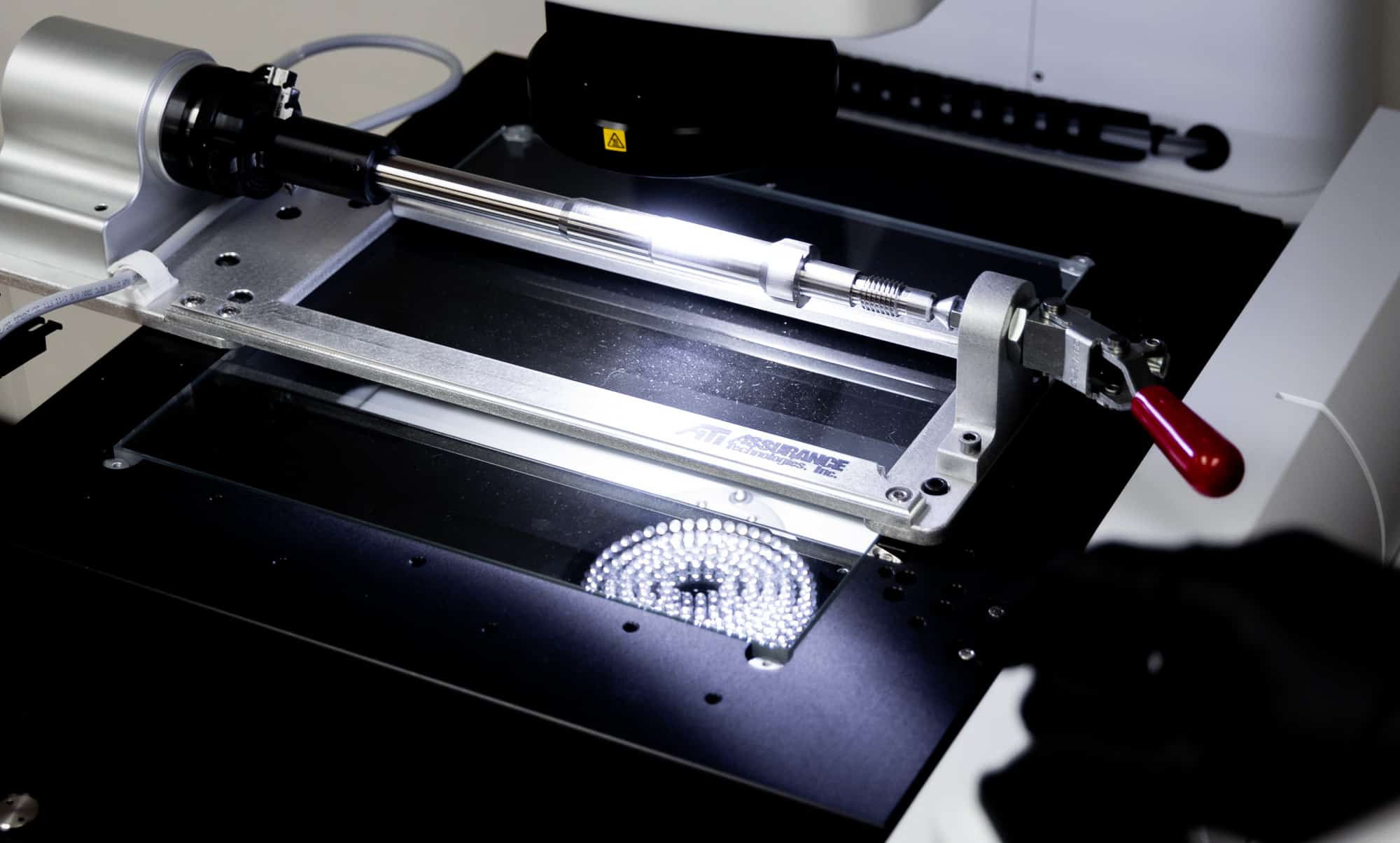

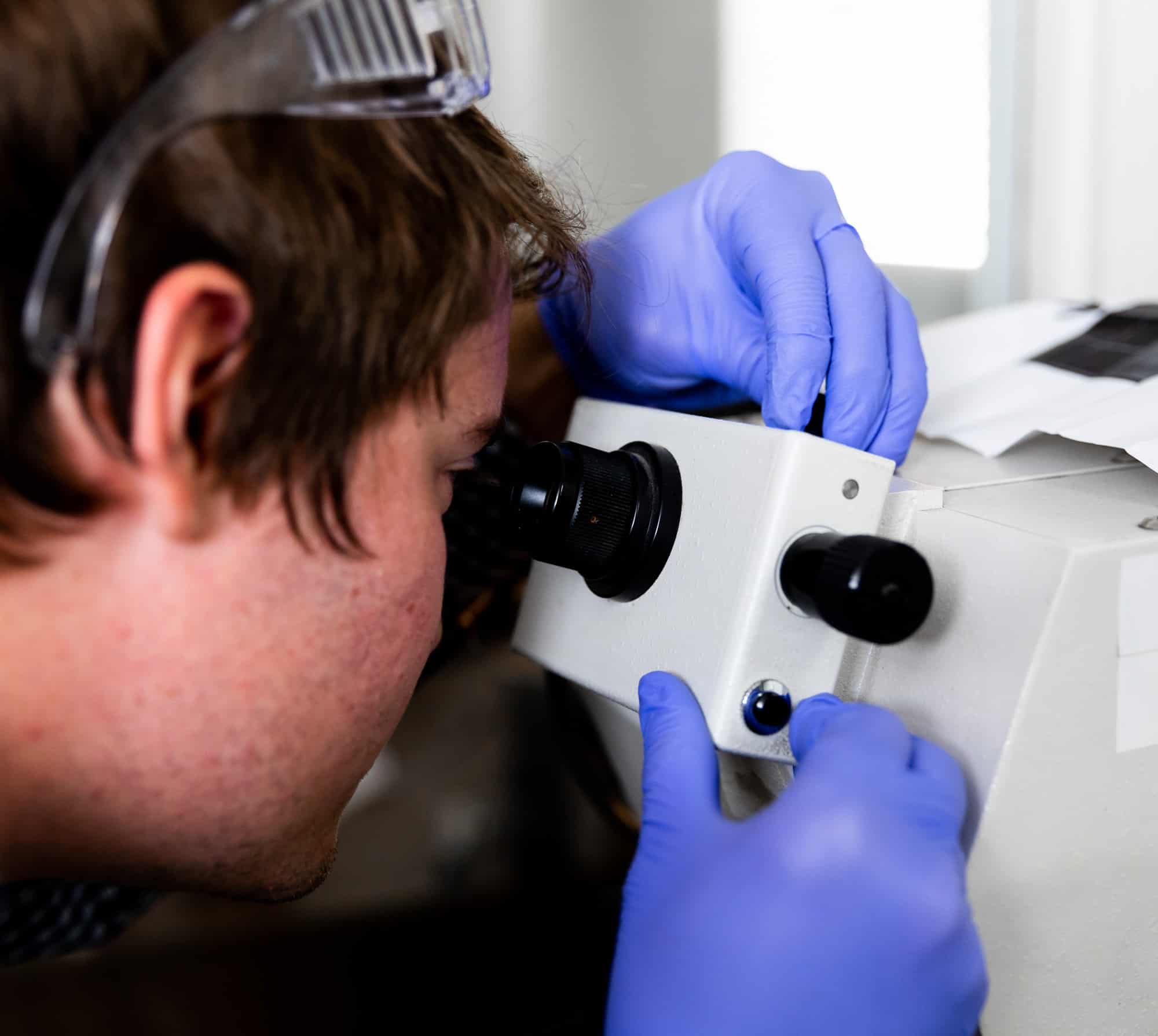

Test Methods Used to Certify Coatings

- ASTM B117 Salt Spray (Fog) Testing

- ASTM E 376 Measuring of Coating Thickness by magnetic Field or Eddy Current (Electromagnetic) Test Methods

- Fed-STD-141, Method 6192 Taber Abrasion Test

- ASTM 487 Measurement of Metal and Oxide Coating Thicknesses by Microscopical Examination of a Cross Section

- D4060, Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser

- ASTM 499 Measurement of Coating Thickness by the Magnetic Method

- ASTM B504 Measurement of Thickness of Metallic Coatings by the Coulometric Method

- Hydrogen Embrittlement ASTM F519

- ASTM B 568 Measurement of Coating Thickness by X-Ray Spectrometry

- ASTM F519 Mechanical Hydrogen Embrittlement Testing of Plating Processes

- Microhardness of Materials ASTM E 384

- ASTM B571 Qualitative Adhesion Testing of Metallic Coatings

Nyflon® Features & Benefits

Self-lubrication

Reduces friction, wear, and galling between sliding components, extending component life without the need for additional lubricants

High corrosion resistance

Protects components from corrosive environments, particularly in harsh chemical or saltwater environments

Uniform coating distribution

Ensures consistent coverage over complex geometries & internal surfaces

Non-stick surface

Prevents materials from adhering to component surface, simplifying cleaning processes & reducing downtime for maintenance

Good hardness

Provides enhanced wear resistance, crucial for components subject to constant or heavy mechanical contact

Thermal stability

Maintains performance characteristics in a wide range of temperatures – suitable for parts used in high-heat applications

Electrical insulation

Can act as an insulator in certain applications, providing safety and functionality in electrical & electronic components

Low coefficient of friction

Enhances efficiency of moving parts, reducing energy consumption & improving overall system performance

Non-wetting surface

Repels water & other fluids – an advantage in applications where moisture or fluid resistance is crucial

Chemical resistance

Protects against a wide range of chemicals, making it suitable for use in chemical processing industries

Ductility

Retains good high-temperature properties, ensuring the coating does not become brittle under thermal stress

Reduces operating noise

Beneficial for bearings, slides, and cylinder/piston assemblies

The Science Behind Nyflon

How it Works

Nyflon® is a co-deposit of electroless nickel and PTFE (Teflon©) that works as an effective, versatile application for a variety of metal surfaces. These include all common tool steels, stainless steel, copper, brass, and aluminum.

Using evenly dispersed nanoparticles of PTFE throughout the coating matrix, Nyflon can significantly improve the lubricity and release properties of a wide range of surfaces. This process differs from similar industrial Teflon® coatings, which only apply a topcoat of PTFE—leaving surfaces at risk for wear.

Nyflon works particularly well for release applications, especially when applied at deposits of .0002”-.0006” (5.08 – 15.24 µm). This gives Nyflon a co-efficient of friction as low as .07—making it optimal for industries such as packaging and blister-pack molding, in addition to release applications such as plastic molding and thermo forming.

Teflon® is a registered trademark of THE CHEMOURS COMPANY FC, LLC.

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Need hardness with release? Let’s explore Nyflon coating.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.