Yes, we are happy to work with suppliers to choose the right coating, develop a robust process, and identify the ideal processing partner to fit any application. Learn more about our process on our How It Works page.

The Purpose of Aerospace Coatings

Benefits of Aerospace Plating Services from Armoloy

Metal failure mitigation

Armoloy protective coatings have helped mitigate risk from a wide range of metal failures.

Improve performance

We produce solutions that prevent metal failure while increasing cycle times.

Reduce downtime

Armoloy helps protect your metal assets by reducing the need for maintenance and making maintenance more predictable

Decrease costs

In addition to reduced downtime, Armoloy coatings are a cost-effective way of meeting performance requirements instead of using an exotic or expensive base metal.

Regulatory compliance

Select Armoloy locations are certified to NADCAP, AS9100, and ISO 9001—with plating lines compliant to industry standards including AMS 2438 and AMS 2460.

Long-lasting solutions

Our performance for over 65 years and constant innovation provides continual value for your business

Global reach

Armoloy operates a total of 10 processing facilities across 8 U.S. states, as well as 6 international facilities located in individual countries spread throughout 3 continents

Turnkey partnership

We’re with you throughout the entire process, acting as a single point of contact for all deliverables

Why Choose Armoloy?

Start-to-Finish Surface Solutions

- Armoloy stands out with our fully staffed metallurgical laboratory dedicated to research and development. We offer comprehensive surface coating services, guiding you from initial consultation through design, application, and final quality checks to ensure optimal results for your project.

Innovative Process Development

- Our innovation center focuses on developing and validating repeatable and reliable processes, which we can then implement at any process fulfillment location. This ensures consistent, high-quality coatings no matter where your project is completed, maintaining the same high standards across the globe.

Global Fulfillment and Logistics

- With fulfillment centers located around the world, we optimize logistics to ensure your coatings are delivered on time and maintain consistent quality, no matter where you are. Our extensive global network allows us to efficiently serve clients worldwide.

Process Accreditations at Armoloy

Our coatings and applications processes have been thoroughly tested to qualify for rigorous industry accreditation such as ISO 9001:2015, REACH and RoHS Compliance.

- AS9100D

- ISO 9001:2015

- ISO 14001:2015

- REACH Compliance

- NADCAP

- ISO 19011

- RoHS Compliance

- WEEE Compliance

Coating Specifications at Armoloy

Armoloy has a long history of involvement and success in the aerospace industry. Our coatings have been thoroughly tested using standard industry specifications such as AMS 2438 and custom specifications created by leading aerospace companies.

- AMS 2438

- AMS 2406

- ASTM B650

- AMS 2403

- AMS 2404

- ASTM B733-22

- AMS 2460

- ASTM A967

- QQ-P-320

- MIL-C-26074

Aerospace Coatings Applications

Applying the Armoloy coatings can improve the long-term performance and longevity of these aerospace parts applications, as well as many others:

- Ball, swivel, universal & slip joints

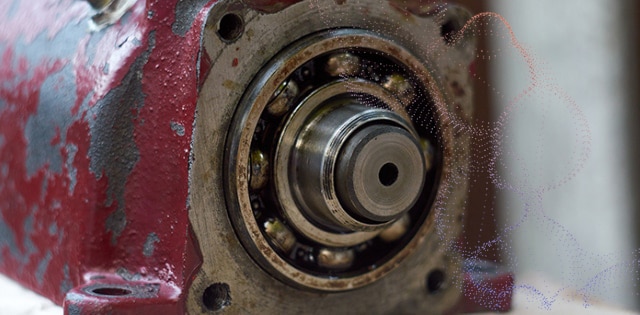

- Bearing Surfaces

- Bushings

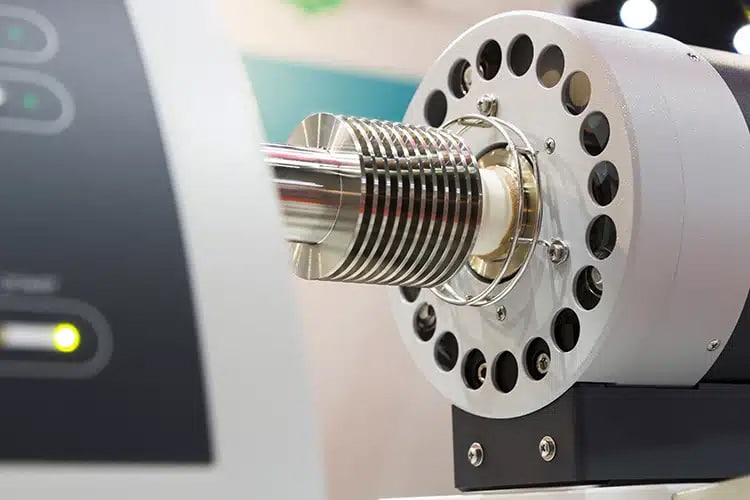

- Compressors

- Cylinders

- Gears & Sprockets

- Hydraulic valves, pistons & housings

- Impellers (air, water, oil)

- Linear motion guides

- Piston rings & rods

- Power transmission systems

- Pump shafts & liners

- Specialty fasteners

Frequently Asked Questions

Aerospace coatings must be durable yet lightweight, able to adhere to a variety of substrates, and withstand mechanical stress and temperature fluctuations. They also need to meet strict regulatory standards, such as AS9100 and NADCAP, while being cost-effective and sustainable.

Corrosion-resistant aerospace coatings, such as electroless nickel plating, are designed to protect metal parts from oxidation and chemical damage. These coatings form a barrier that helps aircraft components resist corrosion even in highly corrosive environments.

While Armoloy coatings can be applied to complex geometries, some extreme shapes may require special considerations or alternative coating methods to ensure complete coverage.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.