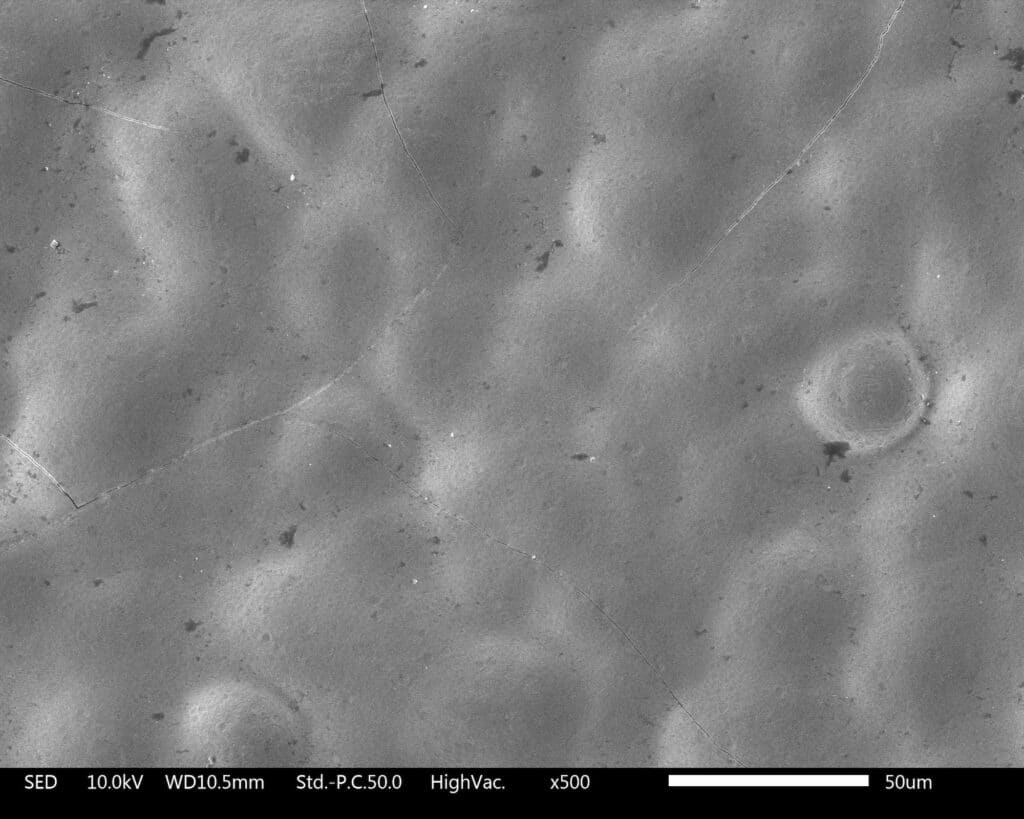

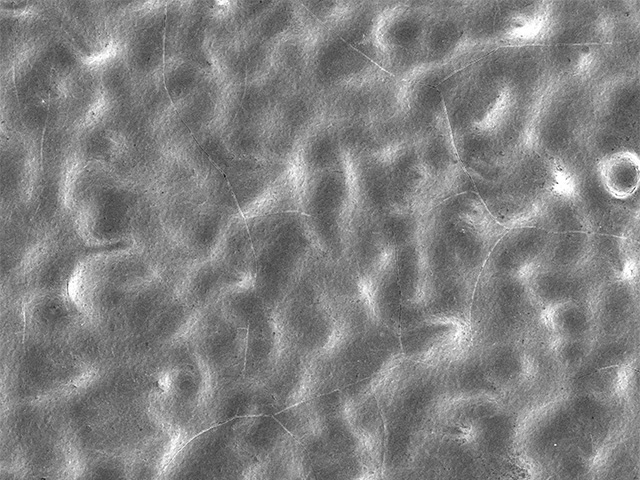

Unlike hard chrome plating, TDC is engineered for tight-tolerance parts with minimal dimensional change and, depending on the texture, emphasizes reduced microcracking and improved wear/corrosion behavior. Moreover, hard chrome often requires post machining processes whereas thin dense chrome avoids the extra time and cost altogether.

Armoloy Coatings

What is Thin Dense Chrome?

Details About Armoloy Thin Dense Chrome

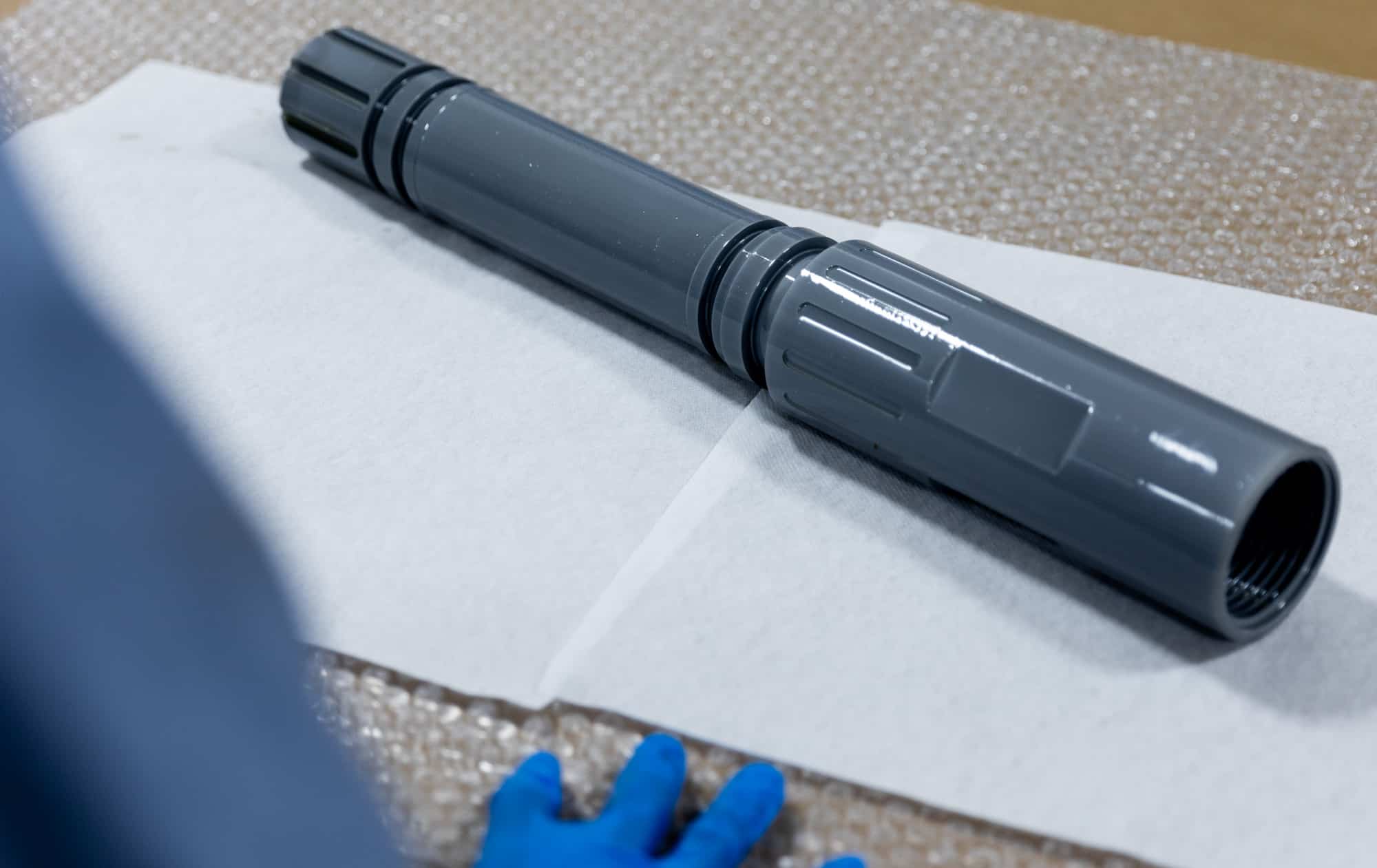

The Armoloy Corporation helps global manufacturers protect their valuable, high-precision components with our various compositions of Thin Dense Chrome plating.

Thin Dense Chrome (TDC) is a pure metallic zero valence chromium coating that eliminates and prevents metal failures and improves machine performance across a wide range of industries with multiple distinct TDC products. By increasing the longevity of metal surface applications, Armoloy helps ensure that companies avoid unplanned downtime and maintain peak efficiency.

Explore TDC Coatings

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Qualifications

Specifications

Adding Value. Developing Solutions.

With over 65 years of experience, The Armoloy Corporation helps global manufacturers protect their most valuable metal assets with a premium lineup of TDC coatings.

Looking for more metal surface treatments to explore? Armoloy’s nickel coatings eliminate and prevent wear and corrosion across a wide range of industrial applications with multiple nickel coating products. By increasing the longevity of metal surface applications, Armoloy helps to ensure that organizations avoid unplanned downtime and maintain peak efficiency and performance.

Frequently Asked Questions

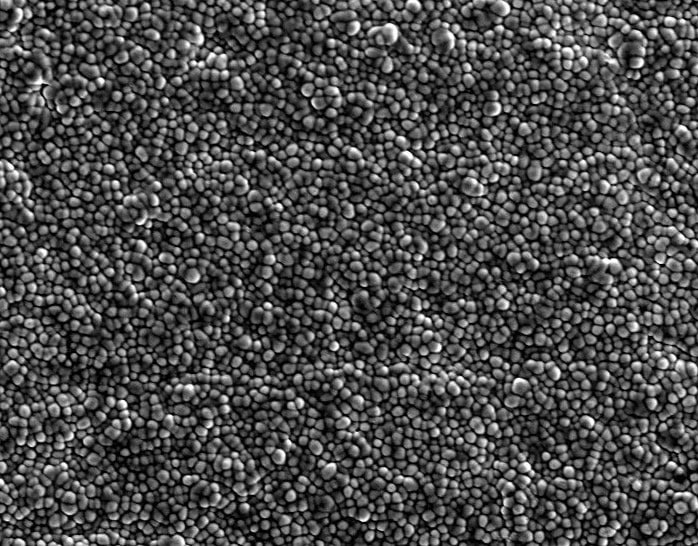

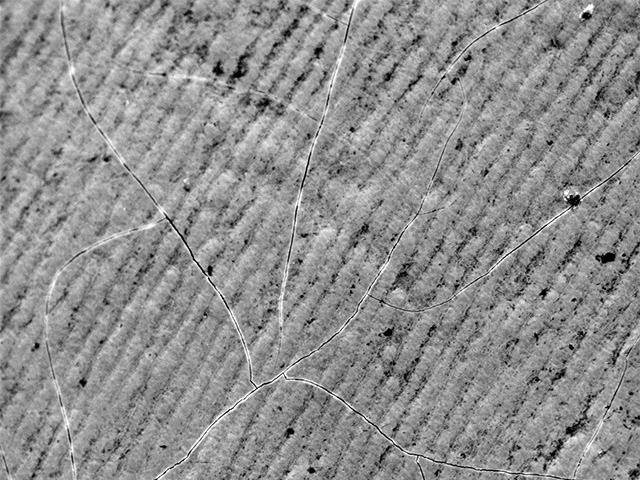

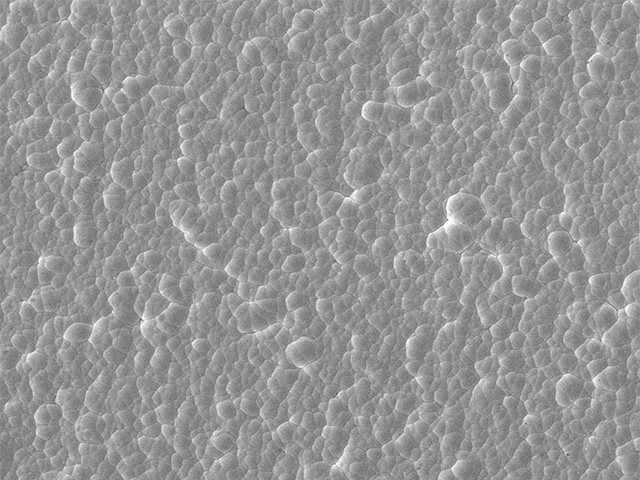

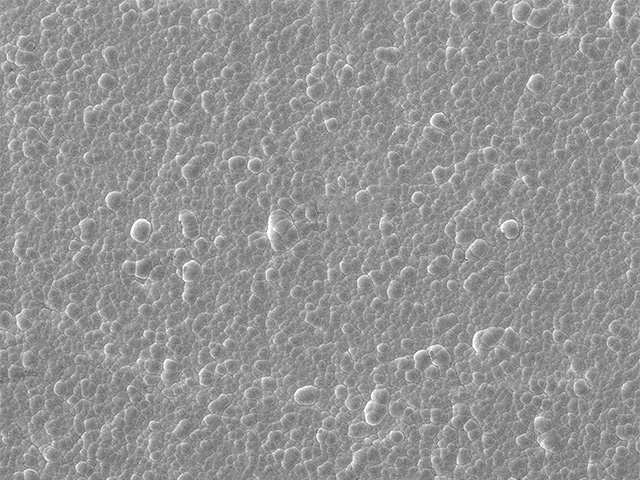

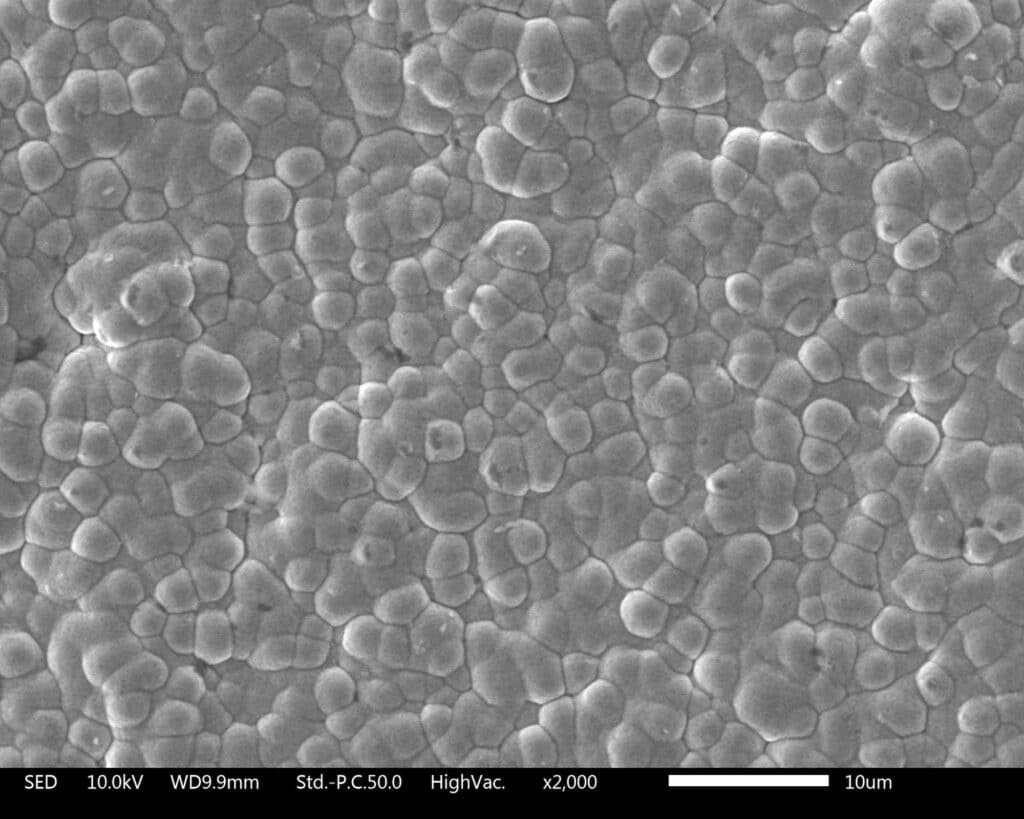

Armoloy provides Nodular TDC, Microcracked TDC (Electrolizing®), XADC® (nano-diamond co-deposit), and hybrids like Bi-Protec (EN+TDC/XADC) and Gullon (TDC + solid-film lubricant) to target specific wear, friction, and corrosion profiles.

Armoloy TDC reaches about 72–78 Rc (depending on variant and process), enabling excellent sliding and abrasive wear resistance. Armoloy nodular thin dense chrome can exceed 78 Rc but the average is typically 78 Rc.

Both—Armoloy’s TDC reduces wear, friction, and corrosion; nodular TDC in particular is positioned for corrosion mitigation alongside low friction.

Armoloy documents USDA approved/FDA-compliant claims with supporting biocompatibility notes (USP/REACH/RoHS context) for TDC variants used in regulated environments. (Confirm clause-level requirements during quoting.)

TDC produces a uniform matte finish by default; appearance options (e.g., matte, satin, non-reflective) are available with Microcracked TDC.

Yes—Armoloy offers a Microcracked TDC for Aluminum (AL-COAT) option designed for aluminum alloys while maintaining thin, dense deposits.

Partner With Us

Eliminate metal failure from your operations and elevate machine performance. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.