Plating Aluminum Components

Advanced Plating for Aluminum Alloys

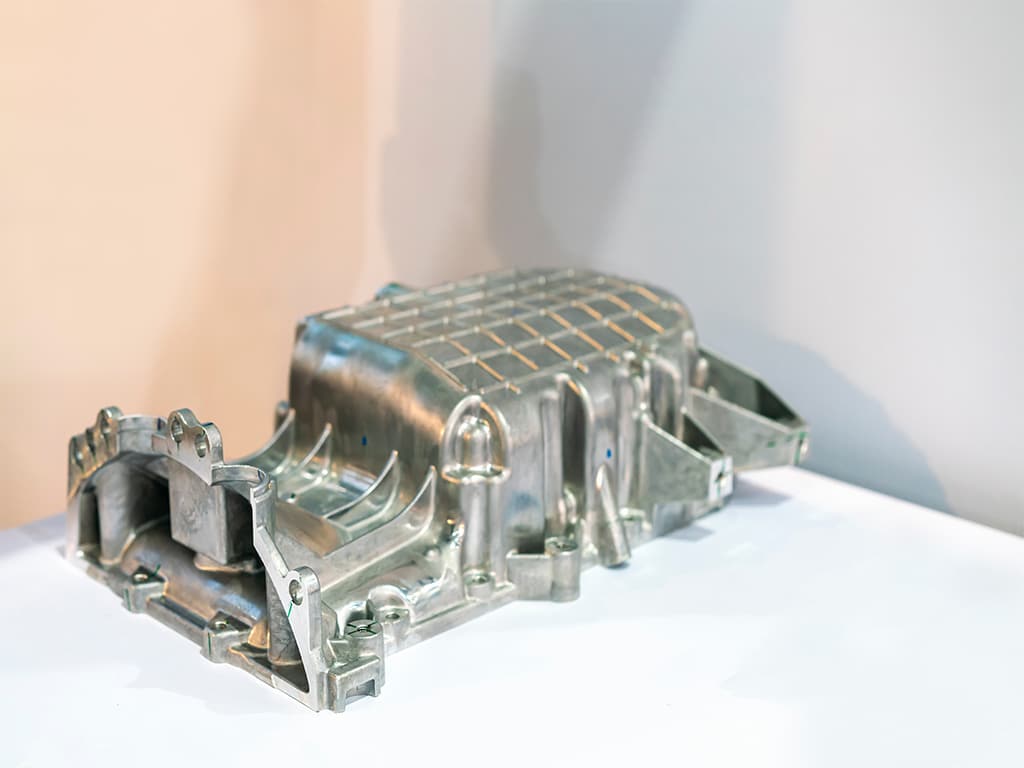

Its benefits, however, extend beyond the medical field. AL-COAT’s strong bond to aluminum resists chipping, peeling, and chemical breakdown—even in corrosive or high-stress environments such as aerospace or oil and gas extraction. With excellent wear resistance and tight adhesion, AL-COAT helps extend part life and improve performance across industries.

Armoloy’s Aluminum Surface Solution

The Armoloy Corporation keeps manufacturing operations up and running around the globe with a broad range of engineered surface solutions.

AL-COAT® stands out for its optimal properties over traditional anodizing when plating aluminum, especially in terms of corrosion resistance. It’s particularly effective against environments with alkaline and chlorinated solutions, reducing the need for frequent maintenance and replacement of medical instruments. The coating’s biocompatibility and antimicrobial properties, along with its inert and non-magnetic nature, ensure safety in medical use. Overall, AL-COAT® offers a blend of enhanced protection, functionality, and aesthetic appeal for aluminum medical instruments, making it a significant advancement in medical coating technologies.

Performance Characteristics

AL-COAT® by the Numbers

- Surface hardness up to 72Rc

- .09 Coefficient of friction

- Wear resistance less than 1.2 TWI*

- Density of 7.19 g/cm ̄3 at 20°C

- Thermal expansion range of 2.7 to 4.6 (10 ̄6/°F)

- Deposited as low as .000050 to .001″ (1.27 to 25.4 µm)

- Withstands temperatures above 1000°F (538°C)

- Low processing temperature < 180°F (<82°C)

AL-COAT Highlights

- Engineered for aluminum substrates

- High hardness

- Excellent wear resistance

- Improved corrosion protection

- Lower friction coefficient

- Enhanced lubricity

- Prevents galling

- Finishing options for aesthetic appeal

Proven applications

Applying AL-COAT can improve the long-term performance of applications within the following industries, as well as many others:

Certifications

- USDA Approved

- FDA Compliant

- ASTM F519

- ASTM B571

- BAC 5709

- https://armoloy.com/plating-specifications/astm-b117/ASTM B117

- USP 10993-10

- USP 10993-6

- https://armoloy.com/plating-specifications/ams-2460/">AMS 2460

- USP 10993-11

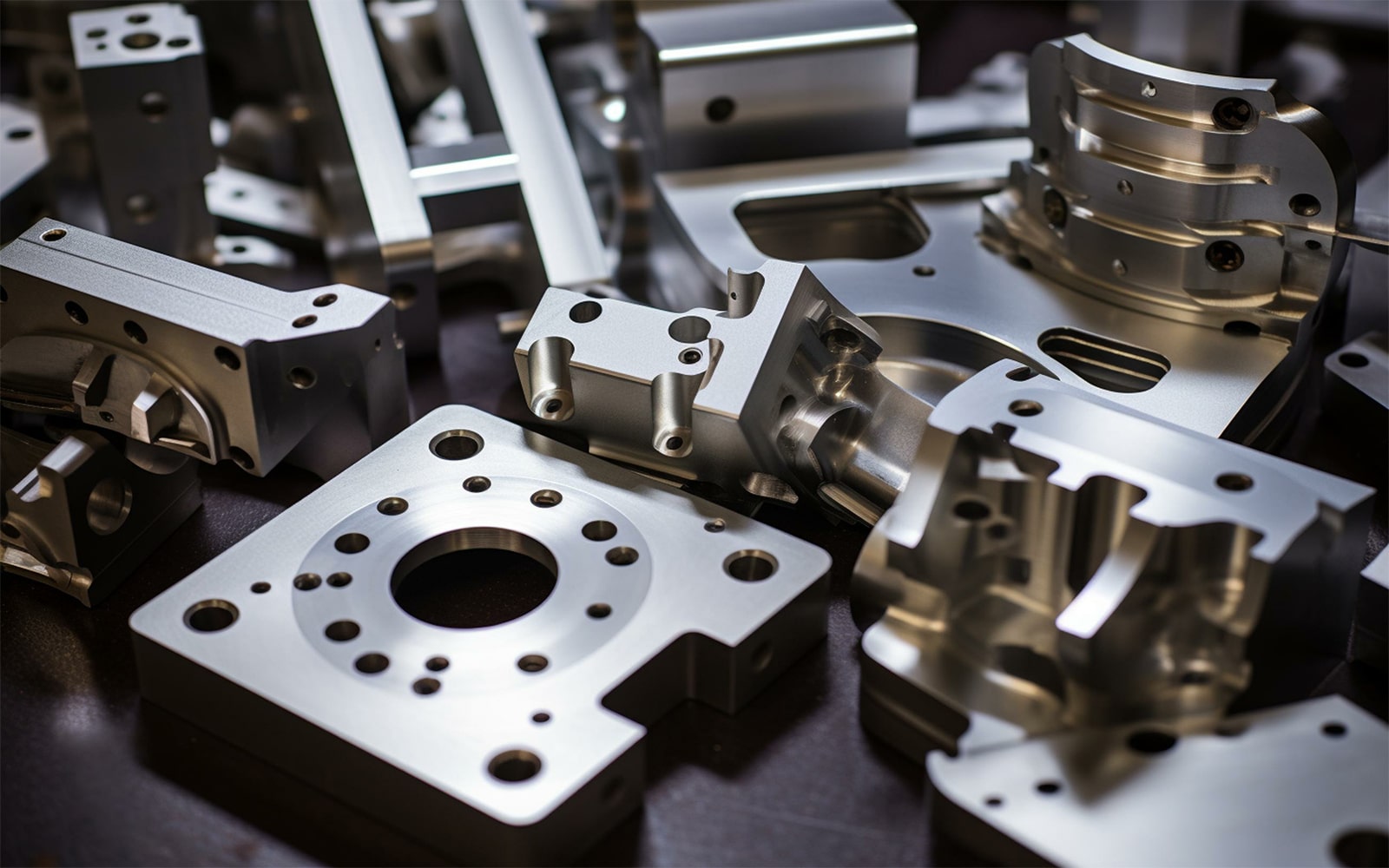

Aluminum Protection (AL-COAT) Features & Benefits

Biocompatible

Certified safe for use in medical devices and instruments, as well as clean-room applications

Compatible base metals

Formulated and perfected specifically for application on Aluminum substrates

Wear resistance

Superior wear resistance over anodizing

Diverse appearances

Three finishes are available to suit your specific application: Non-reflective, Platinum, and Satin

No sharp edge buildup

Minimized dimensional change. Does not require post-machining processes

Low processing temperature

Won’t distort base material and eliminates annealing

Excellent adhesion

Won’t chip, flake or peel from the base material

Effective at thin deposits

Won’t affect strict part tolerances and adheres well to complex geometries

Pure metallic non-toxic chromium coating

USDA approved and FDA compliant, non-toxic coating

Galling protection

Excellent resistance to adhesive wear and tolerant of low lube

Chemical resistance

Stable in alkalis, acids, gasses, and solvents

Lubrication retention

Retains wet and dry lubricants on moving surfaces

The Science Behind AL-COAT

How it Works

Capable for use across a wide range of industries, AL-COAT ensures premium protection for aluminum alloys through its advanced technology. In fact, implementing AL-COAT as a surface treatment solution provides performance similar to stainless steel.

AL-COAT differentiates itself from similar coatings by providing a high-chromium alloy that is also both dense and non-magnetic. The coating is also uniform in both its appearance and deposit thickness, which ranges from .000050” to .001” (1.27µm).

Once applied, AL-COAT ensures long-lasting protection and performance. Namely, the coating increases the wear resistance of an aluminum application while reducing surface friction and preventing galling. AL-COAT’s adherence and ductility also ensures longevity in even the most harsh and corrosive environments, leading to significantly less wear and tear over a longer period of time.

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Protecting aluminum parts? Let’s coat for strength and longevity.

Partner With Us

Improve metal surface performance to its highest pinnacle. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.