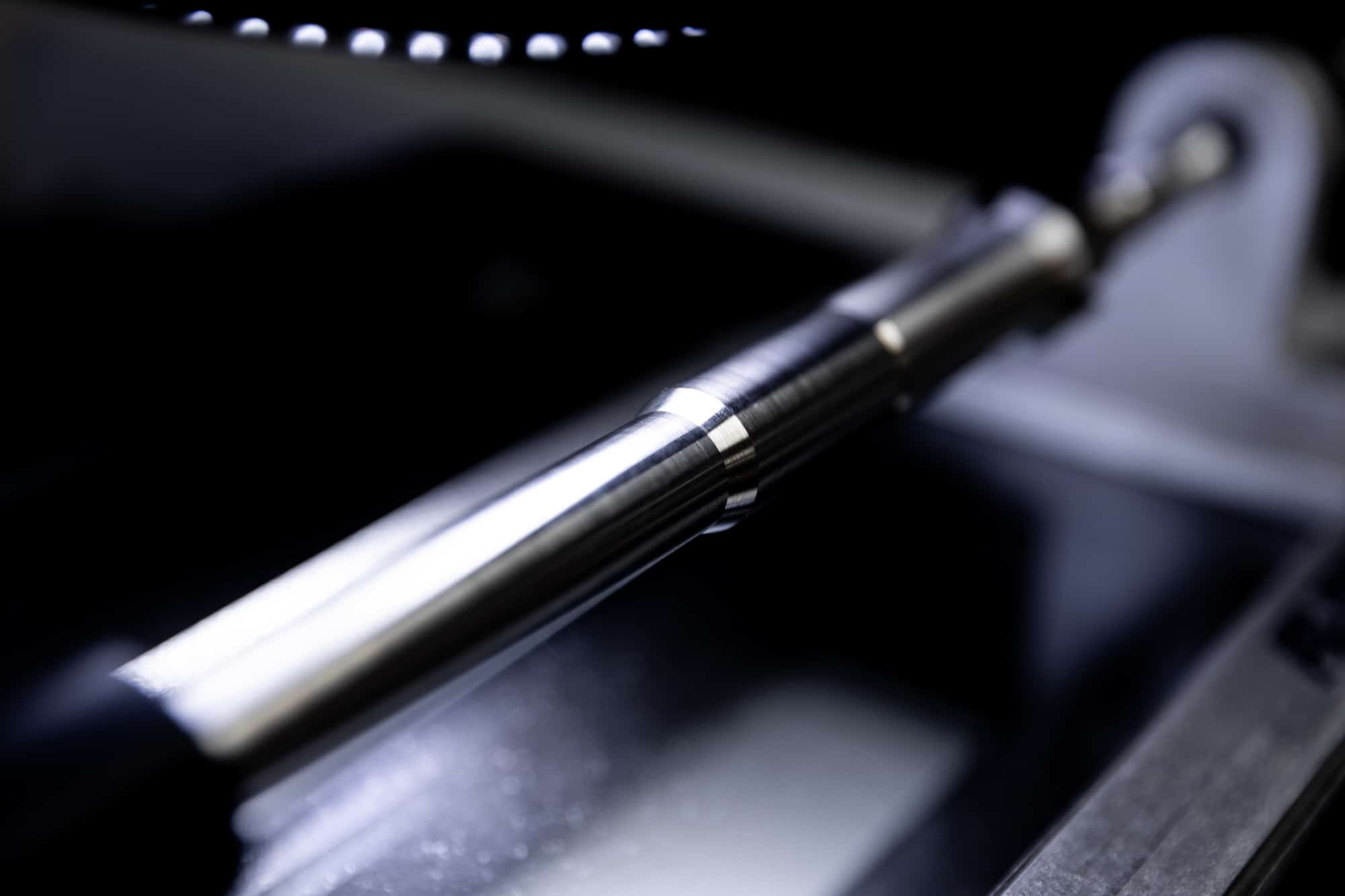

electroless nickel plating

Shield Against Harsh Operating Environments

A Strong Defense Against Corrosion

The Armoloy Corporation continues to help manufacturers worldwide in safeguarding their precision applications with our High Phosphorus Electroless Nickel coating.

The high-phosphorus content confers several key properties to the nickel coating. Due to its exceptional corrosion resistance, it makes the coating highly suitable for components exposed to aggressive or corrosive environments, like those found in oil and gas extraction and coal mining. The hardness of high-phosphorus coatings can exceed 55 HRC, indicating significant durability that rivals the hardness of most heat-treated tool steels. Notably, the structure of these coatings changes with phosphorus concentration. With more than 10% phosphorus, the coating becomes amorphous, as opposed to coatings with less phosphorus that have a microcrystalline structure. Furthermore, the magnetic properties of the coatings diminish as the phosphorus content increases, with coatings having more than 11.2% phosphorus being non-magnetic.

The porosity of the coating decreases with higher phosphorus levels, which in turn enhances its hardness, wear resistance, and corrosion resistance. These features make high-phosphorus electroless nickel plating an ideal choice for extending the life and performance of components used in harsh environments, where reliability and longevity are paramount.

Performance Characteristics

High Phos Electroless Nickel by the Numbers

- 10-13% Phosphorus content

- Deposit range of .0001” to .003” (2.54 to 76.2 µm)

- Up to 67Rc hardness with heat treatment

- Corrosion resistance tested per ASTM B-117

- Up to 67% reduction in coefficient of friction

- Low processing temperature, <200°F (93°C)

- Thermal conductivity 0.010 (Cal/cm/sec/°C)

- Max working temperature of 400°C (752°F)

- Electrical resistivity 75 – 110 (µOHM-cm)

- Coefficient of thermal expansion 8 – 10 µm/m/°C

Armoloy High-Phos Electroless Nickel Highlights

- High corrosion resistance

- Good surface hardness

- Enhanced release

- Thicker deposit available for tool salvage/repair

- Can be combined with TDC for enhanced wear resistance

- Uniform coverage of complex geometries

- Compatible with most ferrous and non-ferrous metals

- Semi-bright appearance

Proven applications

Applying high phosphorus electroless nickel can improve the long-term performance of applications within the following industries, as well as many others:

Certifications

- Fisher General Specification FGS 8B7, Electroless Nickel Coatings

- Fisher General Specification FGS 8B10, Electroless Nickel Coatings

- Aerospace Material Specification SAE AMS2404, Plating, Electroless Nickel

- Aerospace Material Specification SAE AMS2403, Nickel Plating General Purpose

- MIL-C26074 Military Specification, Coatings, Electroless Nickel, Requirements

- Aerospace Material Specification SAE AMS2405, Electroless Nickel Plating Low Phosphorous

High Phos Electroless Nickel Features & Benefits

High corrosion resistance

Amorphous nature of deposit eliminates potential for intergranular corrosion

Ductile and malleable

Retains good high temperature properties

Provides long-lasting protection

Against corrosion, even in harsh environments

Improved acid resistance

Suitable for chemical processing industries, resisting a wide range of chemicals

Reduced porosity

Prevents substance seepage, crucial for hygiene food processing applications

Solderability and conductivity

Easily soldered and provides good electrical conductivity

Hardness

Electroless nickel hardness can be increased with heat treatment, making it suitable for hard surface requirements

Lubricious characteristics

Some electroless nickel processes integrate lubricious particles, further decreasing the coefficient of friction

Can be applied in a cost-effective manner

Saves manufacturing costs while still providing high-quality protection

Shiny and reflective finish

Enhances the appearance of the metal

Good wear resistance

Enhanced durability in high-friction applications by reducing wear and tear

Easily applied onto other metals

Including steel, aluminum, and copper

The Science Behind High Phos Electroless Nickel

Armoloy’s Electroless Nickel plating delivers a uniform, hard, and phosphorus-rich nickel alloy coating across a variety of substrates. This innovative plating process, devoid of electrical currents typically used in electroplating, involves the autocatalytic chemical reduction of nickel ions. The result is a consistent, even layer of nickel-phosphorus alloy that significantly enhances surface properties.

This carefully controlled plating process results in a high-quality, durable nickel coating that maintains the integrity of the original dimensions of the components while providing excellent corrosion resistance in harsh operating environments.

Beyond its formidable shield against corrosion, our Electroless Nickel coating imparts a moderate 46Rc hardness to surfaces, further elevating their resistance to wear. Moreover, this coating emerges as a cost-conscious solution in combating corrosion, offering the flexibility of removal and reapplication, aligning with the dynamic needs of diverse applications.

Services at Armoloy

The Armoloy Corporation is here to support your project from the discovery phase through a successful production launch. Whether coatings are considered during the initial part design phase or a necessity due to product failure in the field, our team can support your needs at any point in the process.

Need even, corrosion-resistant plating? Let’s go electroless.

Partner With Us

Eliminate metal wear and friction from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.