electroless nickel

Protection For Your High-Value Parts

A Tough Shield Against Wear

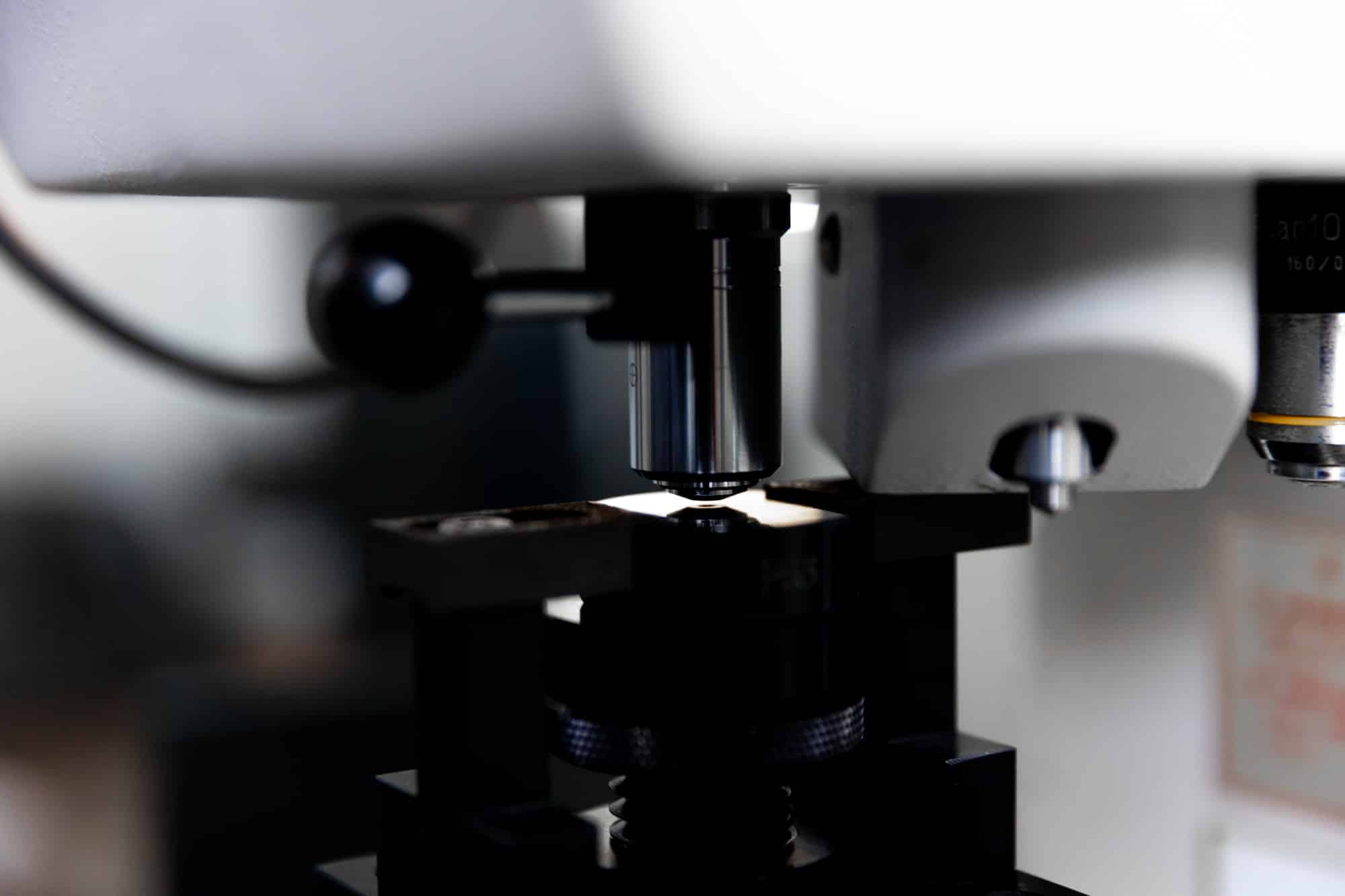

The Armoloy Corporation continues to assist manufacturers worldwide in safeguarding their critical components with our innovative Electroless Nickel coatings.

Our Electroless Nickel (EN) solution is a key player in Armoloy’s line of protective surface treatments, known for its exceptional ability to provide uniform, corrosion-resistant, and hard-wearing coverage. This nickel coating is ideal for a wide range of applications, delivering enhanced durability, wear resistance, and improved surface uniformity. It significantly extends the life of treated components while maintaining their dimensional integrity, making it an indispensable asset for ensuring consistent performance and reliability in various industrial settings.

Performance Characteristics

Mid Phos Electroless Nickel by the Numbers

- 6-9% Phosphorus content

- Up to 70Rc hardness with heat treatment

- Deposit range of .0001” to .003” (2.54 to 76.2 µm)

- Up to 67% reduction in coefficient of friction

- Thermal conductivity 0.012 (Cal/cm/sec/°C)

- Corrosion resistance tested per ASTM B-117

- Low processing temperature, <200°F (93°C)

- Max working temperature of 400°C (752°F)

- Coefficient of thermal expansion 10 – 15 µm/m/°C

- Electrical resistivity 40 – 70 (µOHM-cm)

Armoloy Mid-Phos Electroless Nickel Highlights

- High wear resistance

- Good corrosion resistance

- Improved release

- Good solderability

- Uniform coverage of complex geometries

- Semi bright to bright appearance

- Compatible with most ferrous and non-ferrous metals

Proven applications

Applying an electroless nickel coating can improve the long-term performance of all the following industry-specific applications.

Certifications

- Fisher General Specification FGS 8B7, Electroless Nickel Coatings

- Fisher General Specification FGS 8B10, Electroless Nickel Coatings

- Aerospace Material Specification SAE AMS2403, Nickel Plating General Purpose

- Aerospace Material Specification SAE AMS2404, Plating, Electroless Nickel

- MIL-C26074 Military Specification, Coatings, Electroless Nickel, Requirements Aerospace Material

- Specification SAE AMS2405, Electroless Nickel Plating Low Phosphorous

Mid Phos Electroless Nickel Features & Benefits

Uniform thickness

Ensures consistent protection and performance, even on complex geometries

Ductile and malleable

Retains good high temperature properties

Easily applied onto other metals

Including steel, aluminum, and copper

Provides long-lasting protection

Against wear and corrosion, even in harsh environments

Good wear resistance

Enhanced durability in high-friction applications by reducing wear and tear

Chemical resistance

Suitable for chemical processing industries, resisting a wide range of chemicals

Shiny and reflective finish

Enhances the appearance of the metal

Non-porous surface

Prevents substance seepage, critical for hygiene in industries like food processing

Can be applied in a cost-effective manner

Saves manufacturing costs while still providing high-quality protection

Solderability and conductivity

Electroless nickel can be soldered easily and provides good electrical conductivity

Lubricious characteristics

Some electroless nickel processes integrate lubricious particles, further decreasing the coefficient of friction

Hardness

Electroless nickel hardness can be increased with heat treatment, making it suitable for hard surface requirements

The Science Behind Mid Phos Electroless Nickel Plating

How it Works

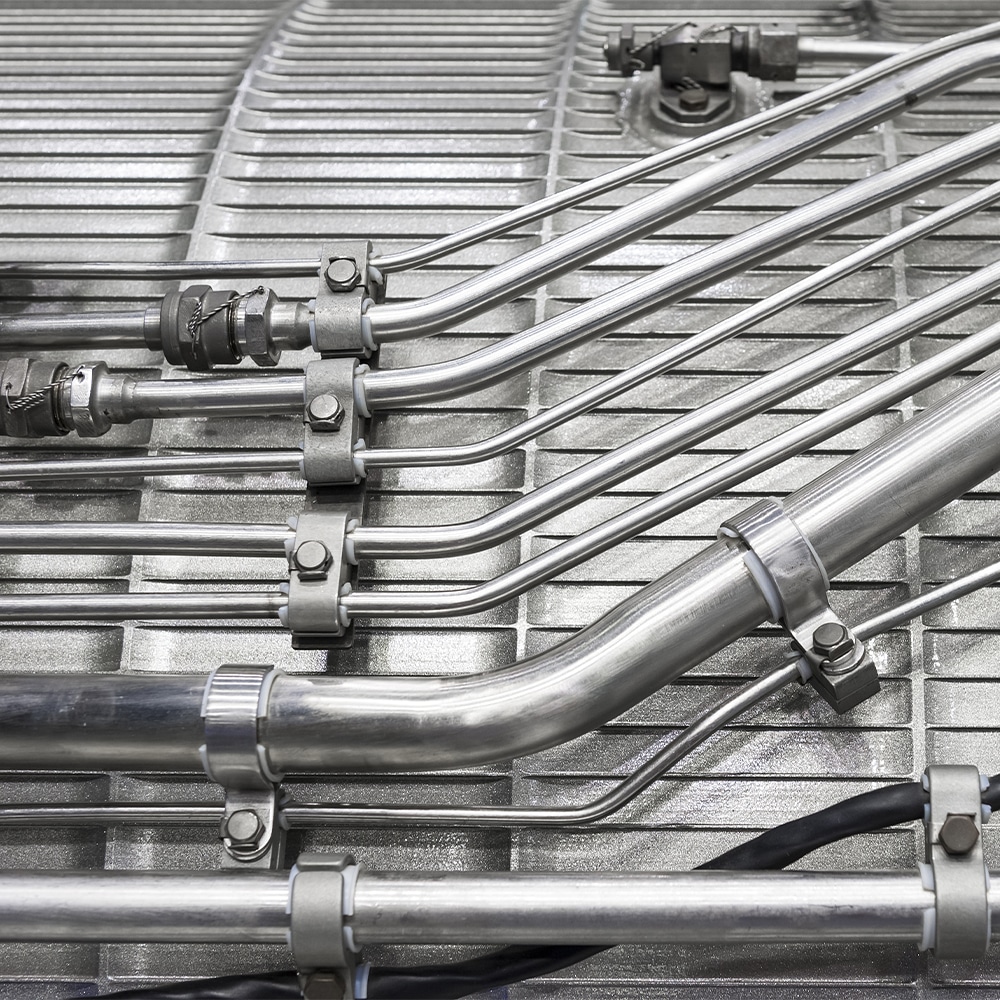

Armoloy works within a wide range of industries to eliminate failures for moderate to severely corrosive applications. Electroless nickel’s high-precision approach ensures uniform coating for all applications during deposit—including its threads, recessed areas, angles, and curves. Based on individual customer requirement, the Armoloy team can apply the coating at a deposit thickness ranging from 0.0001″ to .003″ (2.54 to 76.2 µm).

By combining an even coating with a hard surface and extremely thin deposit, designers can maintain low tolerances while ensuring improved protection and longevity.

In addition to corrosion protection, Electroless Nickel coating adds roughly 45Rc hard deposit to the surface for improved surface wear mitigation. Furthermore, Electroless Nickel plating offers a cost-effective alternative to corrosion-resistant substrates—as users can remove and re-apply the coating as needed.

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Looking for uniform coverage? Let’s apply Mid-Phos.

Partner With Us

Improve metal surface performance to its highest pinnacle. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.