Use electroless nickel when you need highly uniform deposition on complex geometries and strong corrosion protection. Choose electrolytic nickel when you want improved conductivity, aesthetics, or a bright finish and your part geometry supports line-of-sight plating.

Armoloy Coatings

Nickel Plating from Armoloy

Details About Armoloy Nickel Coatings

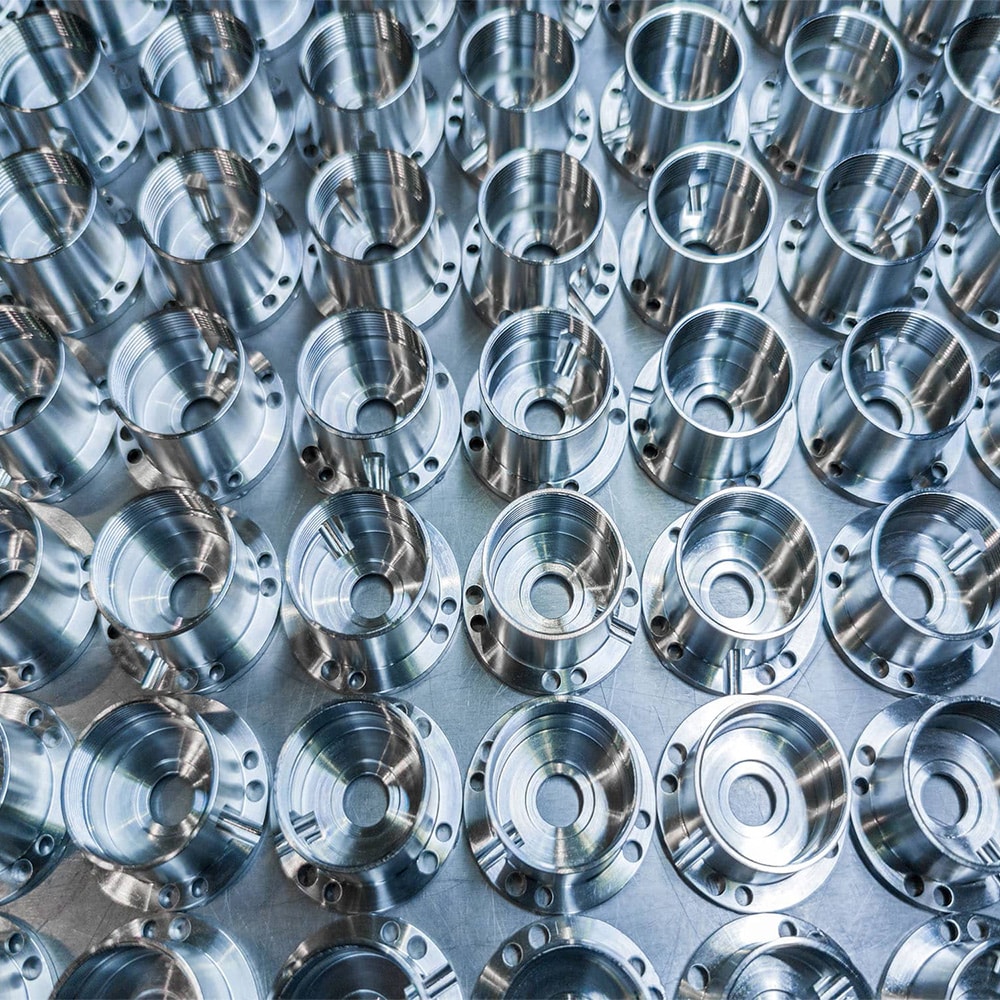

The Armoloy Corporation ensures global manufacturers keep their high precision components up and running with our innovative lineup of nickel coatings.

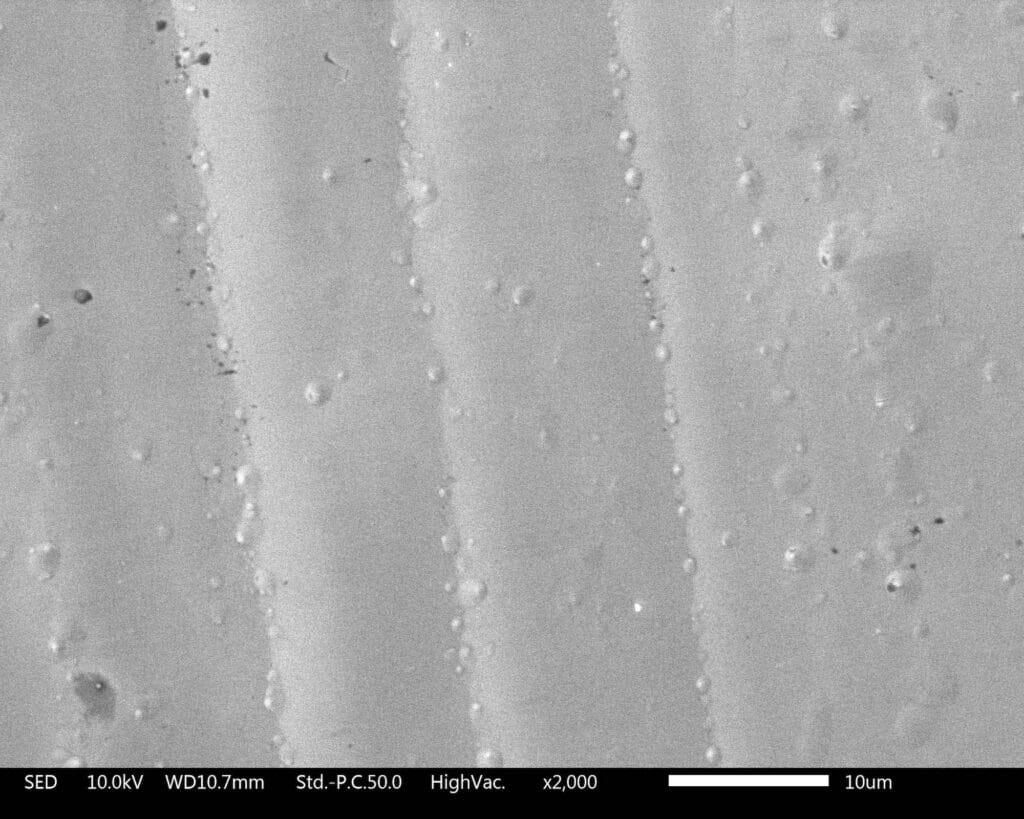

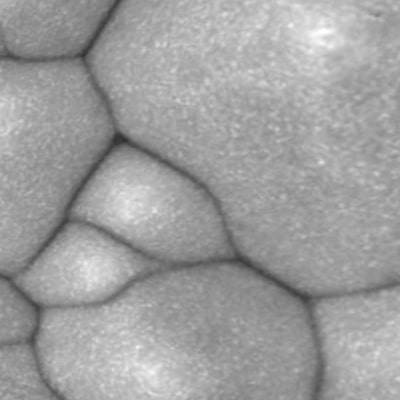

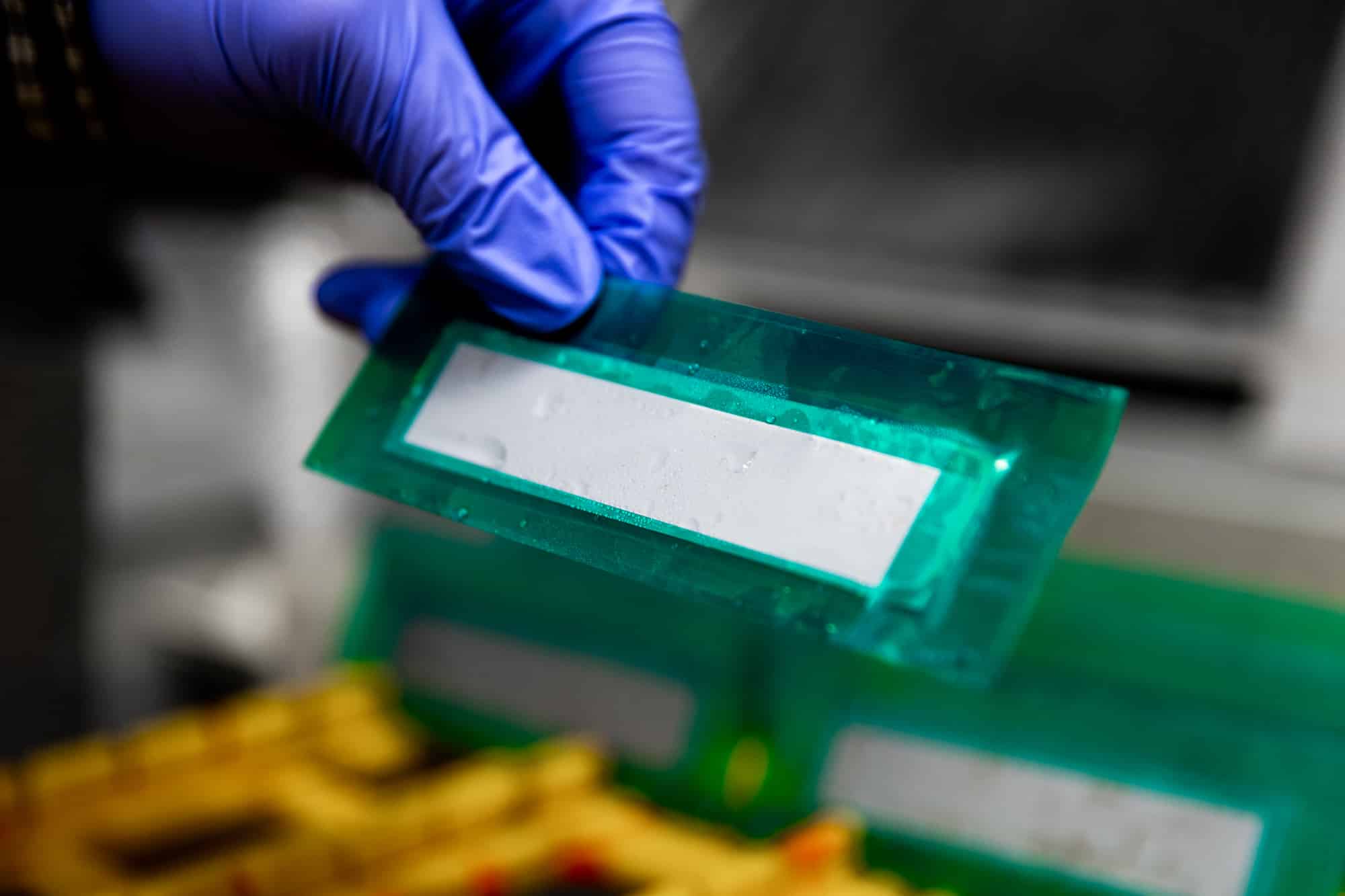

Armoloy specializes in advanced nickel coatings designed to combat moderate to severe corrosion in machined components. Our offerings include mid-phosphorus electroless nickel, a robust functional coating known for its uniform deposition and excellent corrosion resistance.

Additionally, Armoloy provides Nickel Teflon® (Nyflon®), renowned for its unique combination of low friction and release qualities without the use of PFAS additives. These coatings are applied in thin, yet effective layers ranging from 0.0001 to 0.003 inches, ensuring enhanced durability without impacting the dimensional tolerance of parts. This precision application makes Armoloy’s nickel coatings ideal for critical components where both corrosion resistance and dimensional accuracy are paramount.

Explore Nickel Coatings

Services at Armoloy

The Armoloy Corporation is here to provide support for your project, starting from the discovery phase and continuing through a successful production launch. Whether coatings are considered during the initial part design phase or become necessary due to product failures in the field, our team can assist you at any stage in the process.

Qualifications

Certifications & Specifications

Adding Value. Developing Solutions.

With over 65 years of experience in our field, The Armoloy Corporation helps global manufacturers protect their most valuable, high-tuned machined components with a premium lineup of nickel coatings.

Armoloy’s nickel coatings can eliminate and prevent wear and corrosion across a wide range of industrial applications with two distinct nickel coating products. By increasing the longevity of metal surface applications, Armoloy helps to ensure that organizations avoid unplanned downtime and maintain peak efficiency and performance.

Frequently Asked Questions

Typical nickel thickness ranges from 0.0001″ to 0.003″, chosen to meet your functional and dimensional requirements.

Nyflon® is an electroless nickel + PTFE co-deposit that combines corrosion protection with low friction and release properties—useful where clean release and dry-film lubricity matter. Nylfon® is a PFAS-free process.

Yes—Armoloy supports widely used standards such as AMS 2403/2404, AMS 2454 (Ni-PTFE), MIL-C-26074, ASTM B733, and related heat-treat/stress-relief specs (e.g., AMS 2759 series). We’ll confirm clause-level compliance during quoting.

Yes—Armoloy offers R&D test runs, process development/PPAP validation, and scalable production/fulfillment so the qualified process can be repeated at the appropriate facility.

Absolutely. Share your operating media, temperature, geometry, and compliance needs; we’ll advise on mid-phos vs. high-phos EN, electrolytic nickel, or Nyflon® based on corrosion and functional targets.

Yes—Armoloy coordinates quoting, prototyping, and production through its fulfillment model and licensed facilities, making it easy to ship parts in and out.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.