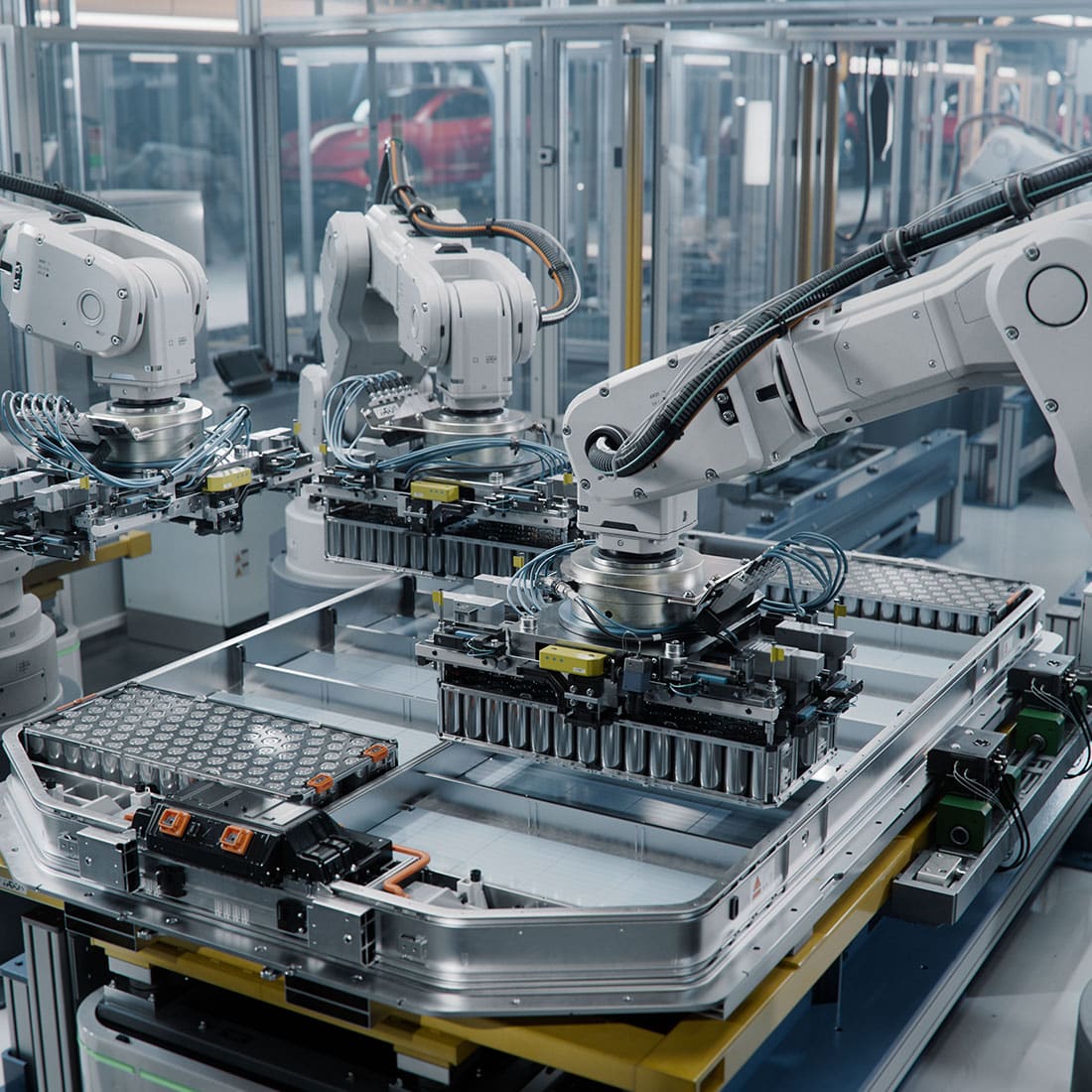

Yes. Armoloy’s thin dense chrome and advanced surface coatings reduce the coefficient of friction between mating surfaces, which can lower energy loss, reduce operating temperatures, and minimize the need for lubrication. In high-volume automotive applications, this contributes to longer maintenance intervals and better fuel or energy efficiency, especially in performance-critical systems.

road tested

Industry-Leading Automotive Coatings

Benefits of Automotive Plating from Armoloy

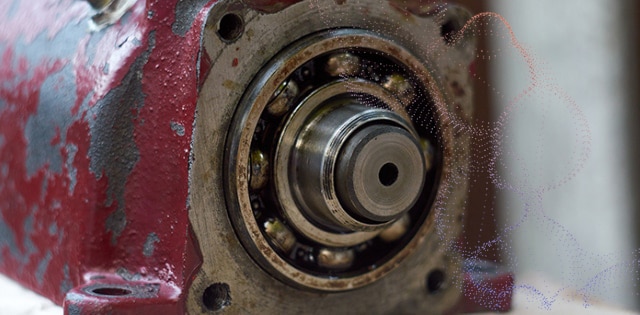

Metal failure mitigation

Armoloy protective coatings have helped mitigate risk from a wide range of metal failures

Improve performance

We produce solutions that prevent metal failure while increasing cycle times

Reduce downtime

Armoloy helps protect your metal assets by reducing the need for maintenance and making maintenance more predictable

Decrease costs

In addition to reduced downtime, Armoloy coatings are a cost-effective way of meeting performance requirements instead of using an exotic or expensive base metal

Regulatory compliance

Select Armoloy locations are certified to NADCAP, AS9100, and ISO 9001—with plating lines compliant to industry standards including AMS 2438 and AMS 2460

Long-lasting solutions

Our performance for over 65 years and constant innovation provides continual value for your business

Global reach

Armoloy operates a total of 9 processing facilities across 7 U.S. states, as well as 6 international facilities located in individual countries spread throughout 3 continents

Turnkey partnership

We’re with you throughout the entire process, acting as a single point of contact for all deliverables

Why Choose Armoloy?

Complete Surface Engineering Support

- At Armoloy, our end-to-end surface coating services are backed by a fully equipped metallurgical lab focused on R&D. From the moment you reach out, we support your project through design consultation, process application, and final inspection—ensuring performance-driven solutions tailored to your needs.

Advancing Process Development

- Our dedicated innovation center is responsible for creating, testing, and refining coating processes that are engineered for consistency. Once validated, these processes are rolled out across all fulfillment locations, guaranteeing dependable results regardless of where your parts are treated.

Global Reach, Local Reliability

- With fulfillment facilities strategically located across the globe, we streamline your logistics while ensuring every coating application meets the same exacting standards. Our worldwide footprint allows us to serve customers efficiently, wherever they operate.

Process Accreditations at Armoloy

Armoloy automotive coatings meet rigorous industry standards and certifications, including:

- AS9100D

- ISO 9001:2015

- ISO 10993

- RoHS Compliance

- NADCAP

- ISO 19011

- ISO 14001:2015

- WEEE Compliance

- REACH Compliance

- NAMSA

Coating Specifications at Armoloy

Armoloy automotive coatings meet rigorous industry standards and certifications, including:

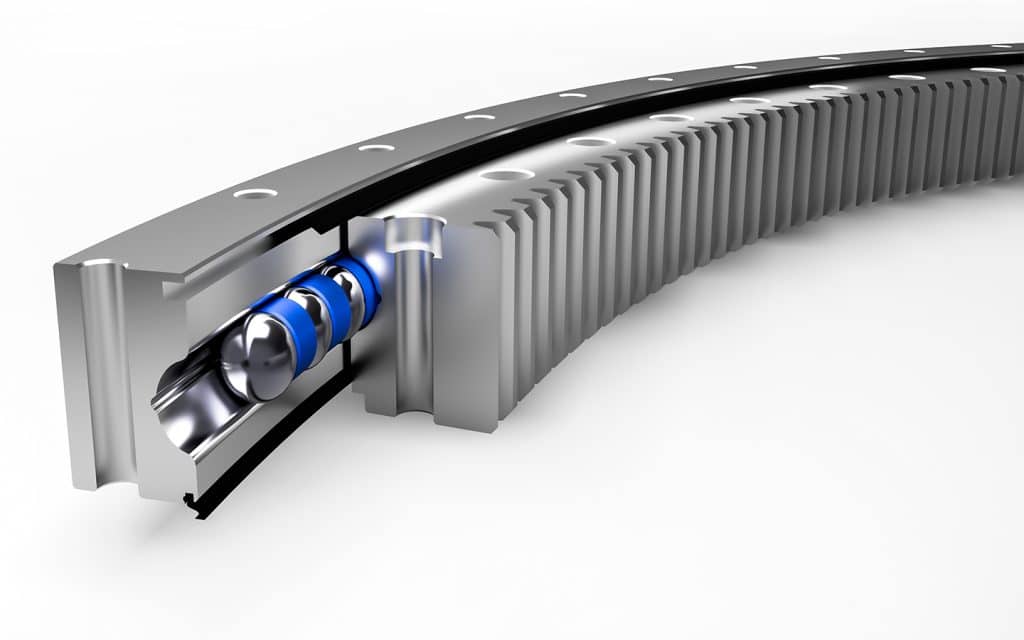

Automotive Plating Applications

Armoloy advanced coatings enhance the performance and longevity of various automotive components, including:

- Bushings

- Cylinders

- Gears & sprockets

- Hydraulic valves, pistons & housings

- Impellers (oil, air, water)

- Piston rings & rods

- Pneumatic percussion tools

- Power transmission systems

- Pumps, Shafts & Liners

- Specialty fasteners

Frequently Asked Questions

EV and hybrid platforms introduce unique challenges such as higher torque loads, tighter packaging, and more severe thermal cycling. Armoloy coatings provide low-friction, high-wear resistance in dry or lightly lubricated conditions and protect against corrosion in lightweight materials like aluminum or magnesium. They help extend part life in high-efficiency drivetrains, battery components, and thermal management systems.

Armoloy coatings are commonly applied to components subject to high friction, wear, or corrosion in the powertrain, drivetrain, fuel systems, and braking systems. These include piston rings, valve lifters, fuel injector parts, gears, cams, and tooling used in production lines. Our coatings improve durability, reduce friction, and maintain dimensional tolerances without flaking or peeling.

Building for performance? Let’s talk coating solutions.

Partner With Us

Eliminate metal failure from your operations. Meet our group of curious, innovative engineers and learn how we can help improve your industry with science-based solutions.