Many are Armoloy-coated. Although single-use devices will only be utilized once, doctors, dentists, and the patients who rely on them need the item’s performance to be maximized. For many types of medical instruments, that means applying a biocompatible chromium coating.

summary

What is Cytotoxicity?

What is a Cytotoxicity Test?

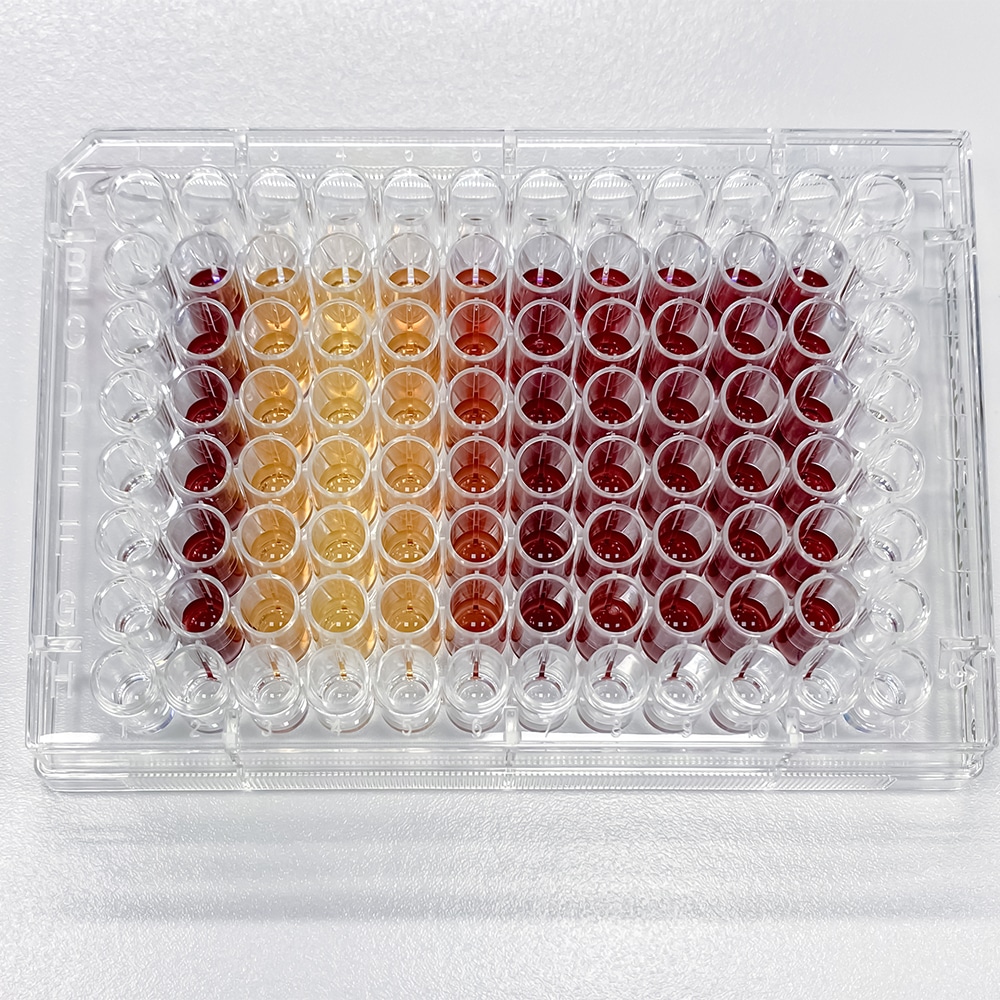

A cytotoxicity test evaluates whether a material (or its extract) causes cell death or damage when introduced to cultured mammalian cells. In this study, ME-92 was tested using the ISO Elution Method, which involves:

- Preparing a test extract in culture medium (1X MEM)

- Dosing cultured L-929 mouse fibroblast cells with the extract

- Incubating for 48 hours at 37°C in 5% CO₂

- Observing cell morphology, growth, and lysis under a microscope

The response is graded on a scale from 0 (no reactivity) to 4 (severe reactivity). A grade of 2 or below is considered non-cytotoxic.

ME-92 Cytotoxicity Study Summary

ME-92’s thin dense chrome coating applied to 304 stainless steel (Lot #38408) was tested by NAMSA, an ISO 13485- and ISO 17025-accredited laboratory.

- Test Result: Grade 0 – No cell damage, lysis, or morphological changes

- Control Performance: All controls functioned as expected, validating the test

- pH Observation: No shift, indicating a stable and non-reactive environment

This confirms ME-92 is non-cytotoxic, safe for cell-contact environments, and compliant with ISO 10993-5 testing requirements.

Why Cytotoxicity Matters

Cytotoxicity testing confirms that ME-92 coatings do not release harmful substances into the body. This ensures material safety for surgical, implantable, or other medical devices—contributing to better healing, reduced complications, and stronger patient outcomes.

Frequently Asked Questions

Yes, as long as the weld is machined and blended. This is a positive application to consider since a welded area is very susceptible to corrosion during autoclave.

Biocompatible coatings enhance the durability, safety, and performance of surgical instruments by preventing corrosion and wear while ensuring they remain safe for use in the body. To learn more about the key benefits and differences between coating types like BIO-TDC and ME-92, read our full blog here.

A disposable medical instrument must perform as well as a reusable device and even disposable instruments require autoclave prior to use. Disposable instruments experience galling and dulling of edges during their short usage, but still must perform to a high level. The ME-92® biocompatible coating reduces these undesirable occurrences.

Partner With Us

Biocompatibility you can trust. Reach out to see how ME-92 coatings meet the highest standards in medical safety and performance.