What is Atomic Force Microscopy?

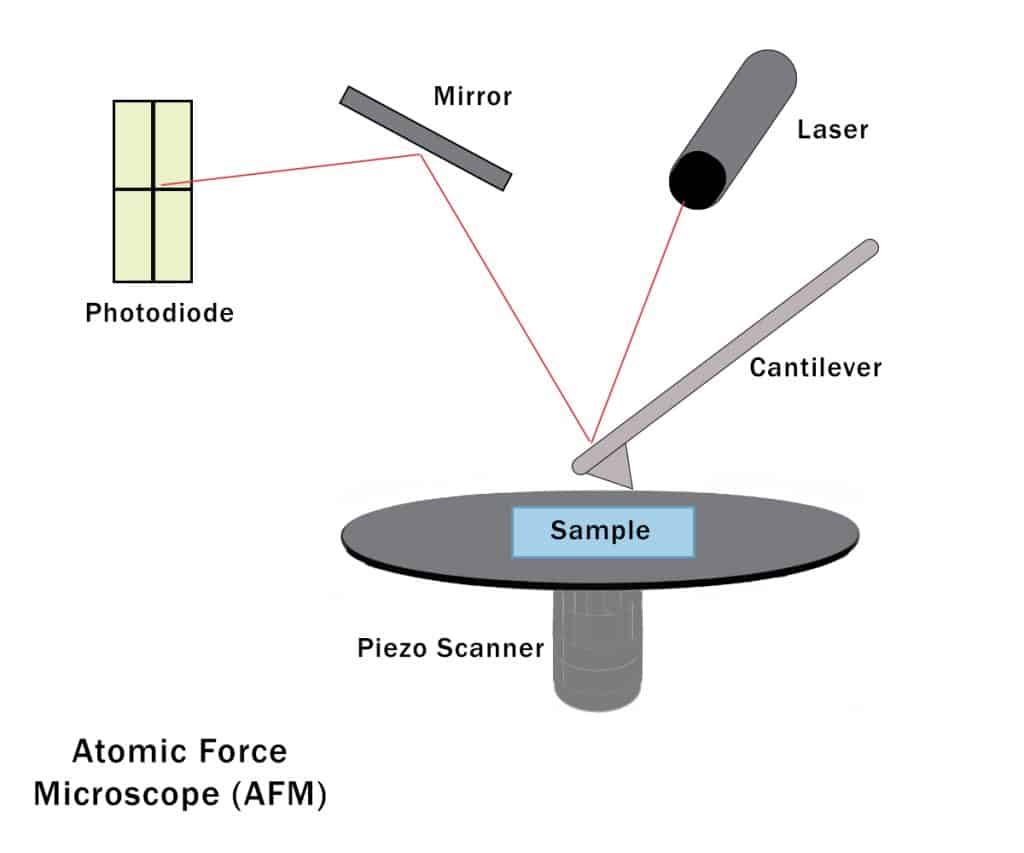

Atomic force microscopy (AFM) is an advanced scanning probe method capable of imaging a wide range of surfaces, such as polymers, ceramics, composite materials, glass, and biological specimens. This technique is useful for assessing various forces like adhesion, magnetic, and mechanical properties. In AFM, technicians affix a finely pointed probe, typically 10–20 nm in diameter, to a flexible cantilever. They usually craft these probes and cantilevers from silicon or silicon nitride. The probe reacts to interactions with the surface, and a laser beam directed at the probe records these movements. A photodiode then detects these movements.

There are two primary operational modes for AFM: contact mode and tapping mode. Contact mode involves continuous contact of the probe with the surface, whereas in tapping mode, the cantilever oscillates, allowing intermittent contact between the probe and the surface. Utilizing the tapping mode minimizes the shear forces generated during the probe’s movement. Tapping mode is predominantly employable for imaging purposes, whereas contact mode is more suits specific tasks like measuring forces. AFM also enables the visualization and manipulation of atoms and structures on different surfaces. The atom at the tip’s apex interacts with surface atoms, forming nascent chemical bonds. These interactions slightly change the vibration frequency of the tip, making it possible to detect and create a map of these changes.

Illustration of the function of an atomic force microscope

Background

The Armoloy Corporation had a case with a surgical device manufacturer who was applying the ME-92 biocompatible thin dense chrome coating to a series of stainless steel bone cutters. They chose the coating for its ability to shield against destructive forces such as corrosion, galling, and excessive wear due to friction. However, concerns arose regarding the stress relief pattern on the surface of the coating. Initially perceived as “cracks,” there was concern that this appearance could negatively impact the coating’s adhesion to the bone cutters.

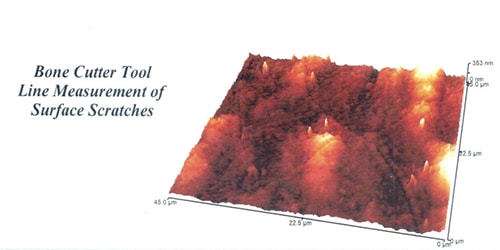

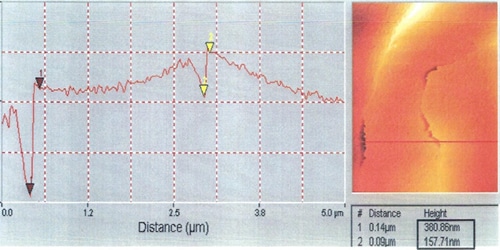

A stainless steel bone cutter coated with ME-92 thin dense chrome, having a thickness of approximately 0.0003” to 0.0005” (7 to 12 microns), was subjected to an in-depth surface analysis using Atomic Force Microscopy (AFM). The primary objective was to ascertain the width and depth of surface signature lines characteristic of the ME-92 coating, typically visible under high-resolution microscopy.

Methodology

The examination employed a TopoMetrix Atomic Force Microscope equipped with a SuperTip probe. A scanning then conducts a specific focus area of 45 micron by 45 micron on the coated surface of the cutter. The study included:

- 3D Surface Imaging: A three-dimensional image of the scanned area was generated, highlighting the surface topography.

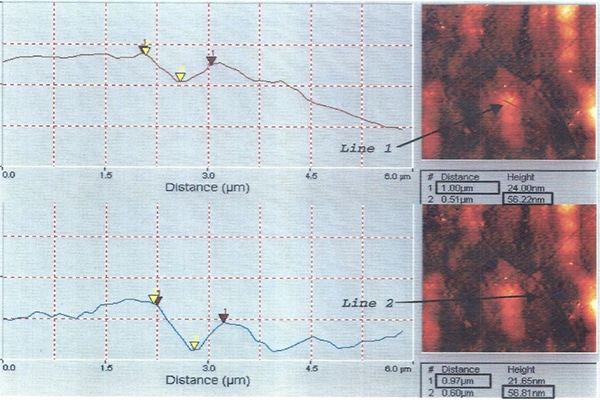

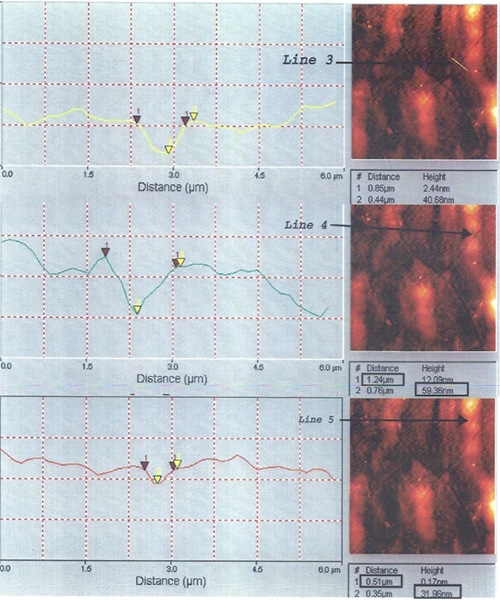

- Line Profile Analysis: Five line profiles were extracted, each accompanied by a 2D image indicating the profile’s origin. These profiles were graphically represented with distinct x and y scales.

- Signature Line Measurement: Using marked pointers on the graphs, the width and depth of the signature lines were measured and analyzed.

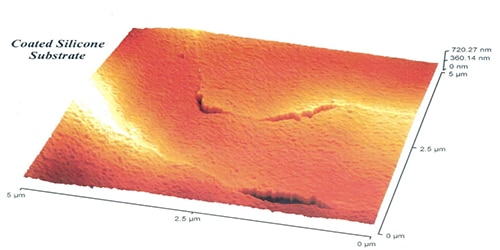

- Comparative Analysis: For sensitivity validation, a comparison is made with scans from a silicone wafer, known to have thinner and deeper surface features.

Results

- Signature Line Dimensions: The average width of the signature lines on the ME-92 coating equates to around 1 micron, with an average depth of about 0.05 microns.

- Surface Integrity: The AFM study revealed no evidence of cracking on the coated surface. Instead, the signature resembled a shallow river pattern.

- Coating Analysis: The observable pattern depth constitutes less than one percent of the total coating thickness, which confirms to be within the expected range of 7 to 12 microns.

- Artifact Identification: Spiked peaks seen in the AFM image identify as surface artifacts, not part of the actual surface topography.

Implications and Further Research

- Surface Quality: The findings confirmed the high quality and integrity of the ME-92 coating, important for the durability and functionality of the bone cutter.

- Instrument Sensitivity: The study demonstrated the AFM’s capability to detect minute surface variations, essential for quality control in precision instruments.

- Future Studies: Recommendations include further research on the impact of the coating on room temperature fracture toughness, adhering to established ASTM standards.

Conclusion

This case study underscores the value of Atomic Force Microscopy (AFM) in precision analysis of medical tool coatings. It showcases its essential role in ensuring the quality and safety of surgical instruments. The study’s detailed examination of the ME-92 coated stainless steel bone cutter not only validates the integrity of the coating but also highlights AFM’s capability to detect minute surface variations. This insight is crucial for advancing medical device manufacturing, where even small surface irregularities can have significant implications. Future research, adhering to ASTM standards, will further leverage these findings, contributing to the development of more reliable medical tools. Overall, this study exemplifies how nanoscale analysis can lead to significant improvements in healthcare technologies and patient care.