Bare metal surfaces can exhibit moderate to high friction, especially in metal-on-metal contact without lubrication. Friction levels depend on several factors:

- Surface Finish: Rough surfaces increase friction; polished or coated surfaces reduce it.

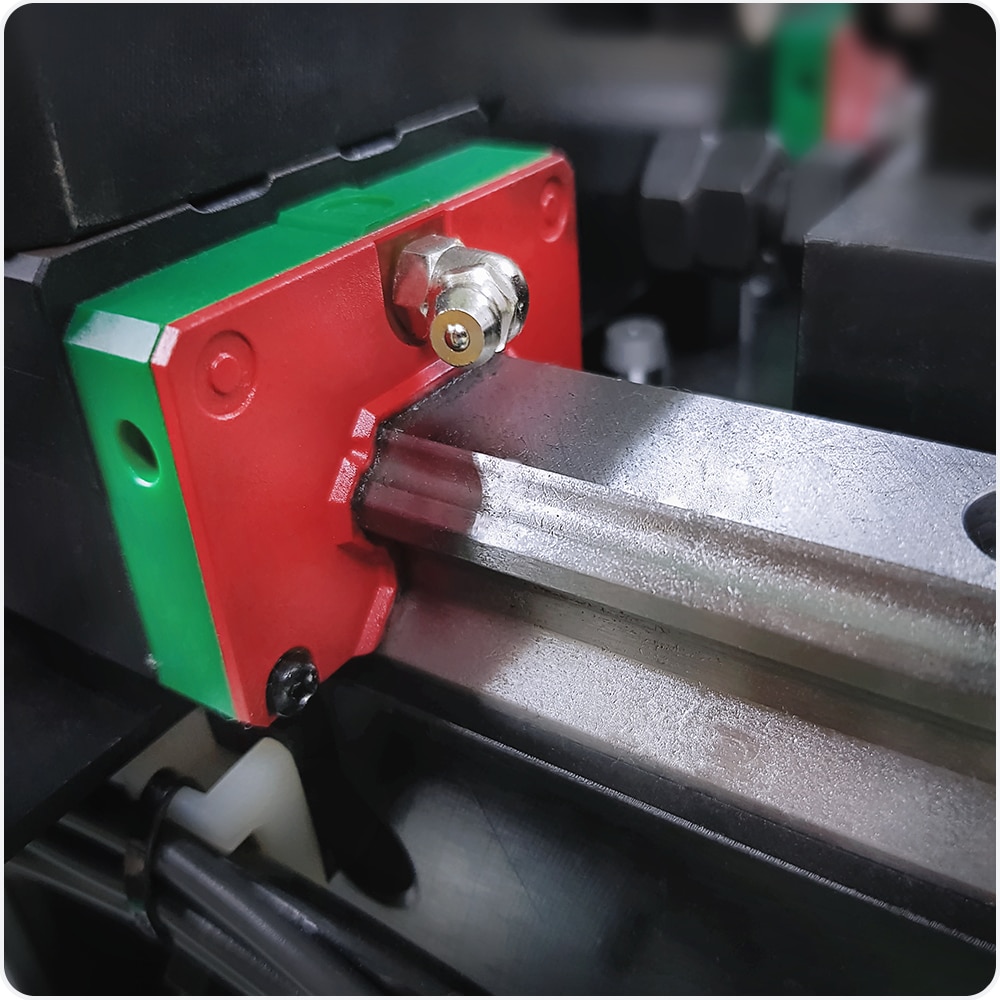

- Lubrication: Oils and greases lower friction significantly; low-friction coatings like Armoloy Thin Dense Chrome (TDC) reduce it even further.

- Material Pairing: Metal-on-metal contact generally has higher friction than metal-on-polymer or ceramic.

- Environmental Conditions: Heat, moisture, and contaminants can all raise or lower friction.

For reference, the dry friction coefficient for steel-on-steel can range from 0.5 to 0.8, while coated or lubricated systems can reduce that to below 0.1. Managing friction is critical in machinery, automation, bearings, and sliding components, where performance and durability are directly affected.