Creep fracture and fatigue fracture are both forms of metal failure but occur under different conditions.

- Creep fracture happens when a material experiences constant stress at high temperatures over a long period, slowly deforming before eventually cracking. It’s common in components like turbine blades, steam pipes, or engine parts.

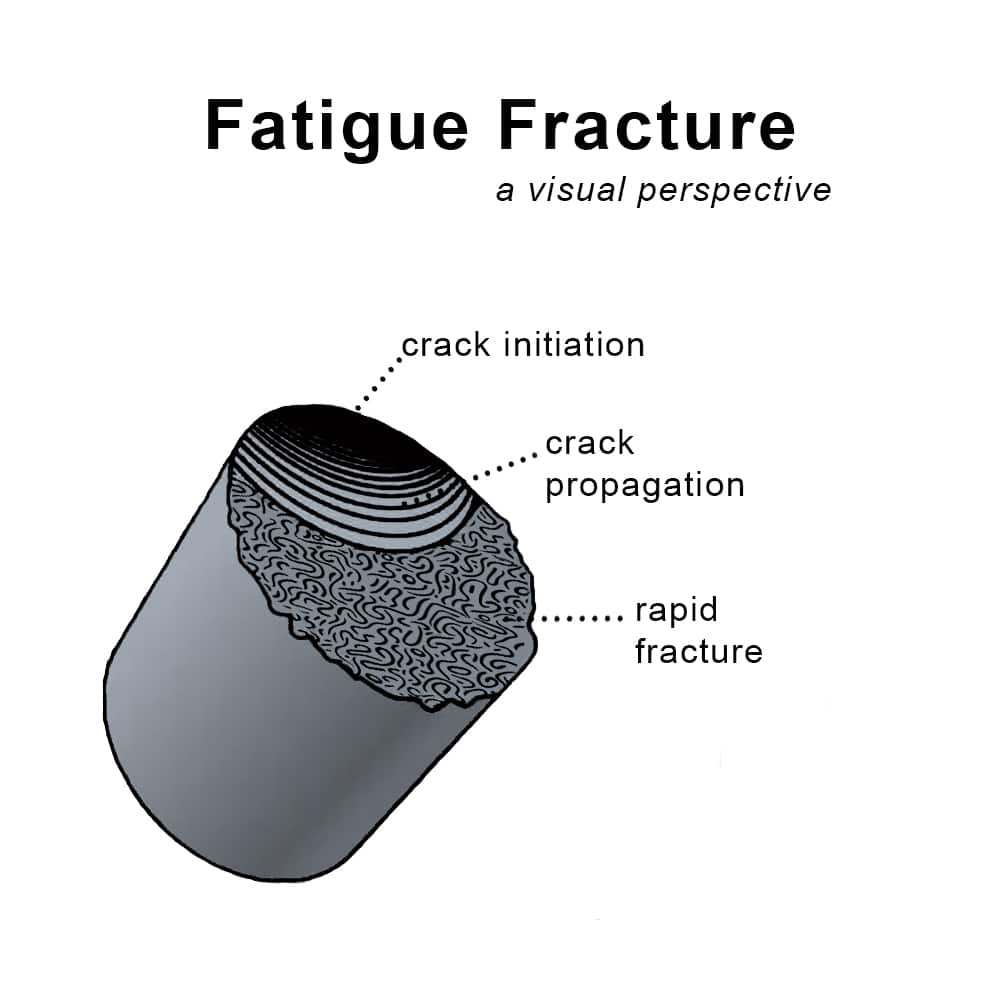

- Fatigue fracture occurs from repeated cyclic loading at normal temperatures, even if stresses are below the material’s yield strength. Over time, small cracks form and grow with each load cycle until the part fractures. Bridges, aircraft, and rotating equipment often experience fatigue-related failures.

While creep is driven by time, temperature, and steady stress, fatigue results from repeated load cycles at varying stress levels.