Introduction

Chemical passivation of stainless steel has been routinely specified to remove surface contamination, such as iron particles and dirt, which would otherwise tend to accelerate corrosion. Technicians often use this treatment before applying biocompatible, anti-wear, and anti-corrosion surface modifications on medical devices. They can eliminate the added expense of passivation by applying a chromium composition coating using the ME-92® technology (ME-92 Operations, Providence, RI) without adversely affecting coating adhesion or corrosion resistance.

This coating is of practical importance because it reduces surface wear, friction, and galling of standard stainless steels. It also provides an effective barrier from the potentially carcinogenic nickel component of stainless alloys. Exposure to nickel bearing alloys has already been regulated by European countries to reduce the occurrence of allergic skin sensitization. This coating has satisfied all the biocompatibility requirements of USP Class VI, plus the additional hemolysis, pyrogenicity, mutagenicity, polar and non-polar sensitization tests necessary for Tripartite/ISO certification for short-term body contact.

Objective

The primary objective of this case study is to evaluate the effectiveness of the ME-92® thin dense chrome coating as a substitute for chemical passivation in enhancing the corrosion resistance and adhesion properties of various types of stainless steels, specifically types 316, 17-4 PH, and 44C. This study aims to determine if the ME-92® coating can effectively replace the conventional chemical passivation process, thereby reducing costs without compromising the corrosion resistance, biocompatibility, and adhesive properties necessary for medical device applications. Additionally, the study seeks to assess the performance of the ME-92® coating in both saline solution exposure and autoclave sterilization conditions, particularly focusing on its ability to prevent nickel leaching and surface wear, and to maintain its integrity under mechanical stress.

Procedure

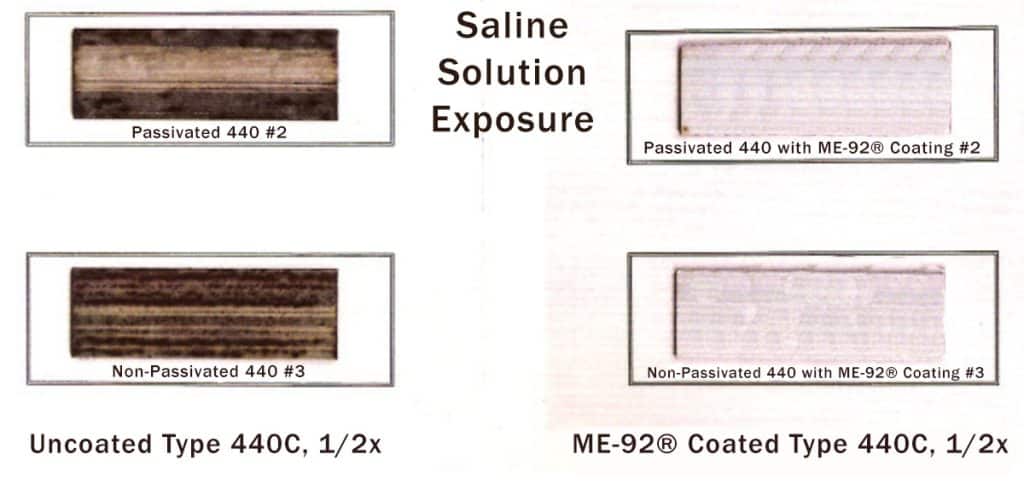

Researchers selected corrosion resistance and coating adhesion tests to evaluate the benefits of chemical passivation before coating deposition. They treated chemically passivated and non-passivated stainless steel coupons of types 316, 17-4 PH, and 440C with a 0.0003” to 0.0005” thick deposit of chromium composition coating using the ME-92® technology. Due to the poor corrosion resistance of type 440C stainless steel, they also exposed uncoated passivated and uncoated non-passivated samples to the corrosion tests. They used these samples to demonstrate the value of the coating for improving corrosion resistance. At the end of each test, they photographed the surface appearances.

Armoloy Researchers immersed two new samples of each type in room temperature isotonic saline solution for two minutes, followed by air drying them in a nearly horizontal position. They visually inspected the coupons for surface discoloration after each drying cycle for a total of 50 cycles. They exposed uncoated samples to 40 cycles.

Autoclave corrosion testing consisted of 30 cycles of exposure to 121°C pure steam for 20 minutes. Two samples of each configuration were tested. At the end of testing, samples were rinsed in distilled water and visually inspected for corrosion and discoloration.

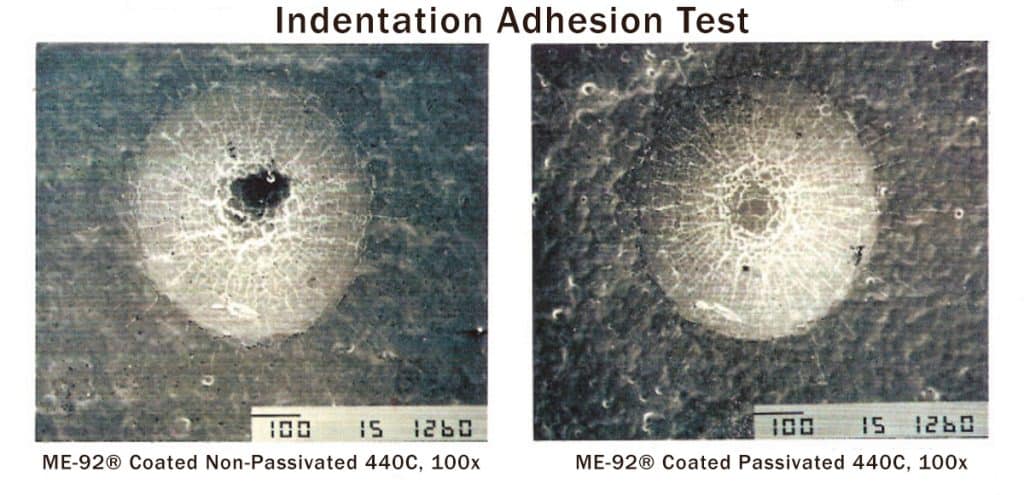

Researchers appraised the adherence of the coating to the base metal using a Rockwell hardness tester in the A-scale configuration. They performed three coating indentations on each type of sample. They examined the edges and bases of the hardness impressions at a magnification of 200x for coating delamination using a JEOL T300 Scanning Electron Microscope (SEM).

Results & Discussion

Results of the corrosion and adhesion tests are summarized in Tables 1 and 2.

Saline Exposure

No corrosion or discoloration was observed on the coated 316 or 17-4 PH samples after 50 cycles, regardless of whether it was chemically passivated before coating.

Surface rusting occurred with all the uncoated samples of passivated and non-passivated 440C. Passivation noticeably increased corrosion resistance of uncoated samples. On coated passivated samples of 440C, minimal staining was observed after the 5th cycle. No further coated sample spotting was observed throughout the rest of the test. The stains were removed with washing. No staining occurred on the coated non-passivated samples.

The 440C material came with an exceptionally rough surface from the mill. No refinishing process performs before coating, providing a worst-case scenario for this test. A smoother surface finish, as those generally used for medical applications, would have greatly enhanced the coating’s performance.

Autoclave Exposure

None of the coated, passivated, and non-passivated 316 or 17-4 PH samples were discolored or corroded after 30 cycles of autoclave sterilization.

Without the coating, non-passivated type 440C samples rusted mildly during steam exposure. Passivation helped to minimize rusting in this environment. Coating of the 440C metal greatly enhanced corrosion resistance. Passivation before coating did not increase the corrosion resistance of 440C material.

Coating Adhesion

In each instance, the coating remained fully adherent to the base metal during deformation, regardless of material type or passivation. The indenter load was high enough to allow full penetration of the diamond through the coating and into the base metal. A stress relief pattern developed around the impressions because of base metal deformation. This appearance is normal for an extremely hard coating (> 75Rc hardness).

Table 1. Effect of Chemical Passivation on Corrosion Resistance and Coating Adhesion of Stainless Steel Coated with ME-92®

Passivated Non-Passivated

| Type | Corrosion | Adhesion | Corrosion | Adhesion |

| 316 | E | E | E | E |

| 17-4 PH | E | E | E | E |

| 440C | E/G | E | E/G | E |

E-Excellent G-Good P-Poor F-Failed

Table 2. Effect of Chemical Passivation on Corrosion Resistance of Uncoated 440C SS

Passivated Non-Passivated

|

Type |

Corrosion | Adhesion | Corrosion | Adhesion |

| 440C | P | …… | F | …… |

E-Excellent G-Good P-Poor F-Failed

Conclusions

Chemical passivation did not improve the corrosion resistance of ME-92® coated stainless steels during exposure to either saline solution or autoclave sterilization.

Chromium composition coating greatly increased the corrosion resistance of type 440C stainless steel to saline solution and autoclave sterilization.

ME-92® shows to be totally adherent to all the types of stainless steels tested, regardless of whether it undergoes passivation prior to coating.

Chemical passivation treatments and their associated costs may be eliminated on many stainless steel applications by using a thin dense chrome composition coating deposited by the ME-92® technology.