Armoloy Specifications

What is AMS 2403?

As a general-purpose standard, AMS 2403 outlines stress relief, surface preparation, plating thickness, and quality control to ensure consistent, high-quality results. It covers everything from flash plating to uniform nickel deposits, balancing functionality with precision.

By following AMS 2403, manufacturers ensure durable, oxidation-resistant coatings that meet industry performance standards.

The Role of AMS 2403 in Electrodeposited Nickel Plating

AMS 2403 sets uniform standards for electrodeposited nickel plating to support precision, quality, and consistency across industries. Its key roles include:

- Detailed Plating Guidelines: Specifies thickness, stress relief, and surface preparation requirements for consistent, high-quality results.

- Support for Tight Tolerances: Helps manufacturers meet exact dimensional and performance specs in high-precision applications.

- Driving Quality Control: Requires strict testing protocols to verify plating durability and performance.

- Application Versatility: Makes it easier to use nickel plating across different metals and industries with one clear standard.

AMS 2403 sets the foundation for nickel plating processes that meet modern manufacturing and global industry standards.

AMS 2403 Testing Methodology and Results

AMS 2403 establishes test methods to ensure nickel coatings perform as intended across industries. Key tests include:

- Preparation of Test Specimens: Select and clean representative samples to remove contaminants before testing.

- Thickness Measurement: Cross-sectioning, X-ray fluorescence, and coulometric tests confirm precise coating thickness.

- Adhesion Test: Bend and thermal shock tests ensure the coating securely bonds to the substrate.

- Corrosion Resistance Test: Salt spray tests evaluate protection against oxidation and environmental exposure.

- Hydrogen Embrittlement Relief: High-strength steel parts undergo baking treatments to prevent embrittlement.

- Stress Relief Treatment: Hardened parts (>40 HRC) are heat-treated before plating to prevent cracking.

- Visual Inspection: Surfaces are examined for uniformity, smoothness, and defects.

These tests confirm that AMS 2403-compliant coatings deliver reliable protection and long-term performance.

Industries That Use AMS 2403

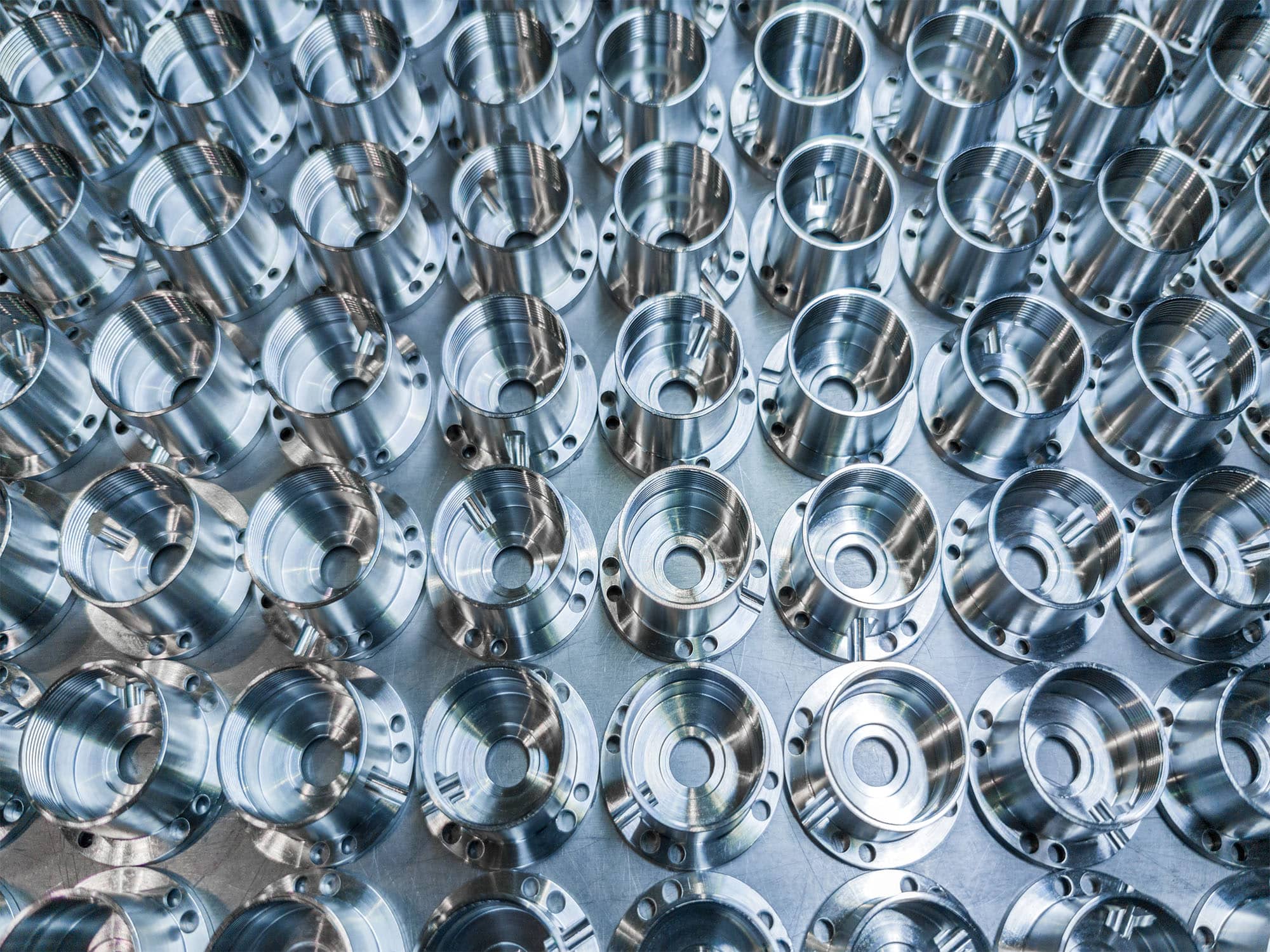

AMS 2403 is widely used in industries where nickel plating enhances corrosion resistance and functionality, including:

- Aerospace: Protects fasteners, brackets, and housings from corrosion and wear in extreme conditions.

- Automotive: Provides long-lasting, high-quality finishes for trim, emblems, and engine components.

- Defense: Shields military vehicle parts, weapon systems, and electronics from corrosion and degradation.

- Medical Devices: Ensures biocompatibility and durability in instruments, implants, and diagnostic tools.

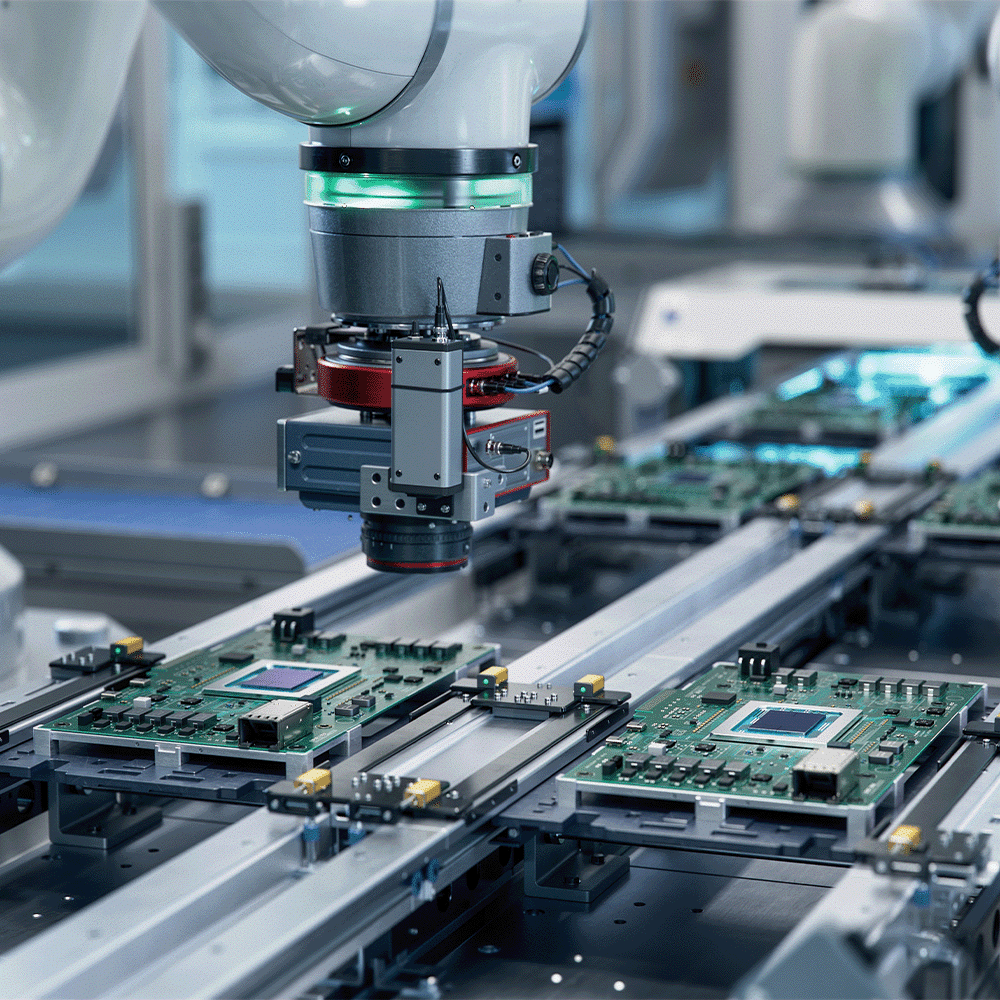

- Semiconductors: Enhances conductivity and corrosion protection for connectors, contacts, and housings.

These industries rely on AMS 2403 to support critical applications across demanding environments.

Benefits of Working with an AMS 2403 Provider

Quality assurance

Adhering to AMS 2403 guarantees that nickel-plated components meet stringent performance, durability, and corrosion resistance standards

Reliable, consistent results

Maintains uniform plating thickness and precise surface finishes across every batch

Regulatory compliance

Providers ensure that parts meet AMS and ASTM standards in alignment with industry regulations

Expert technical support

Specialists assist with material selection and design optimization for specific applications

Enhanced process control

Strict oversight of plating methods and materials guarantees reliable outcomes

Tailored solutions

Providers can customize plating solutions for unique industry and application needs

Comprehensive documentation

Providers maintain detailed records to support traceability, audits, and compliance requirements

Optimized performance

Plated components deliver consistent performance, minimizing the risk of failure and reducing maintenance costs

Specifications at Armoloy

Armoloy offers plating solutions that meet AMS 2403 to support both regulatory compliance and individual project needs. Explore common specifications and accreditations we work with, and contact us to find the right solution for your application.

Disclaimer

The information provided on this page, including any descriptions, interpretations, or summaries related to AMS 2403, is offered solely by The Armoloy Corporation for general informational purposes. This content reflects Armoloy’s internal understanding and practical application of AMS 2403 within its own processes and does not constitute official or authorized guidance from SAE International.

AMS 2403 is a proprietary standard developed and owned by SAE International. Armoloy makes no claim to ownership of this specification and does not reproduce, quote, or distribute any protected content from the original document. References to AMS 2403 are made in accordance with fair use principles and are intended to illustrate Armoloy’s alignment with widely recognized plating standards.

This content is not intended to substitute for the official specification, which should be obtained directly from SAE International. Readers are strongly encouraged to consult the original standard and qualified professionals for definitive technical or compliance information.

The Armoloy Corporation makes no warranties, express or implied, regarding the accuracy, completeness, or applicability of this content and disclaims all liability for any reliance placed upon it. This disclaimer is subject to change without notice and does not create any contractual relationship or obligation.