summary

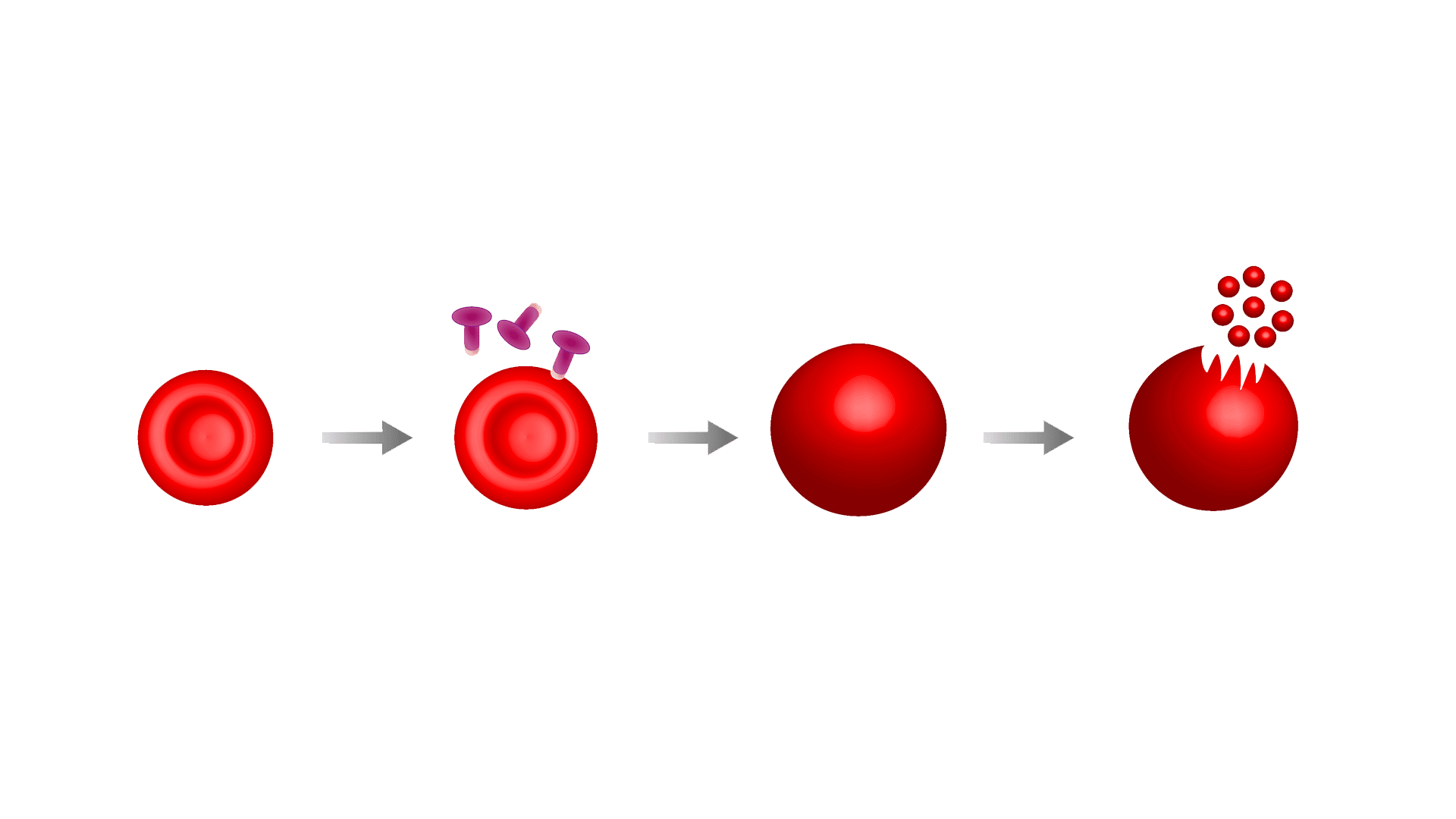

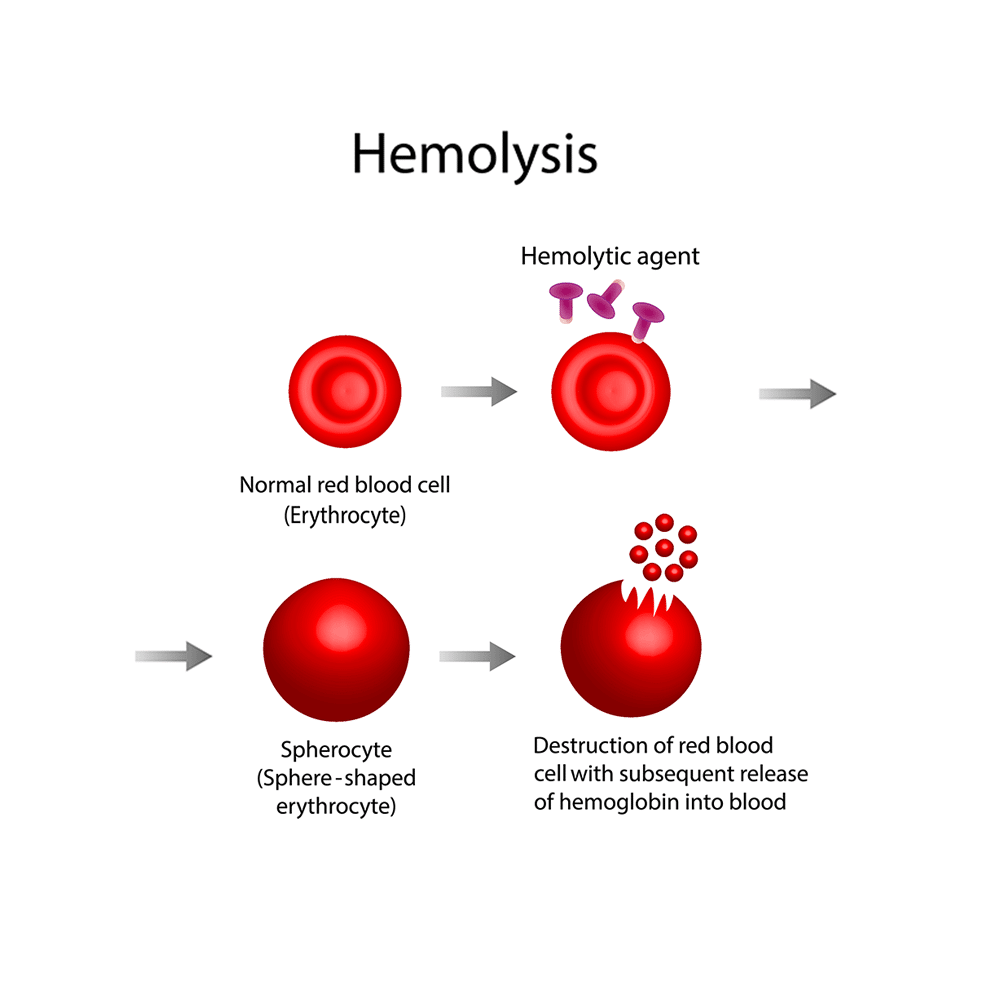

What is Hemolysis?

What is a Hemolysis Test?

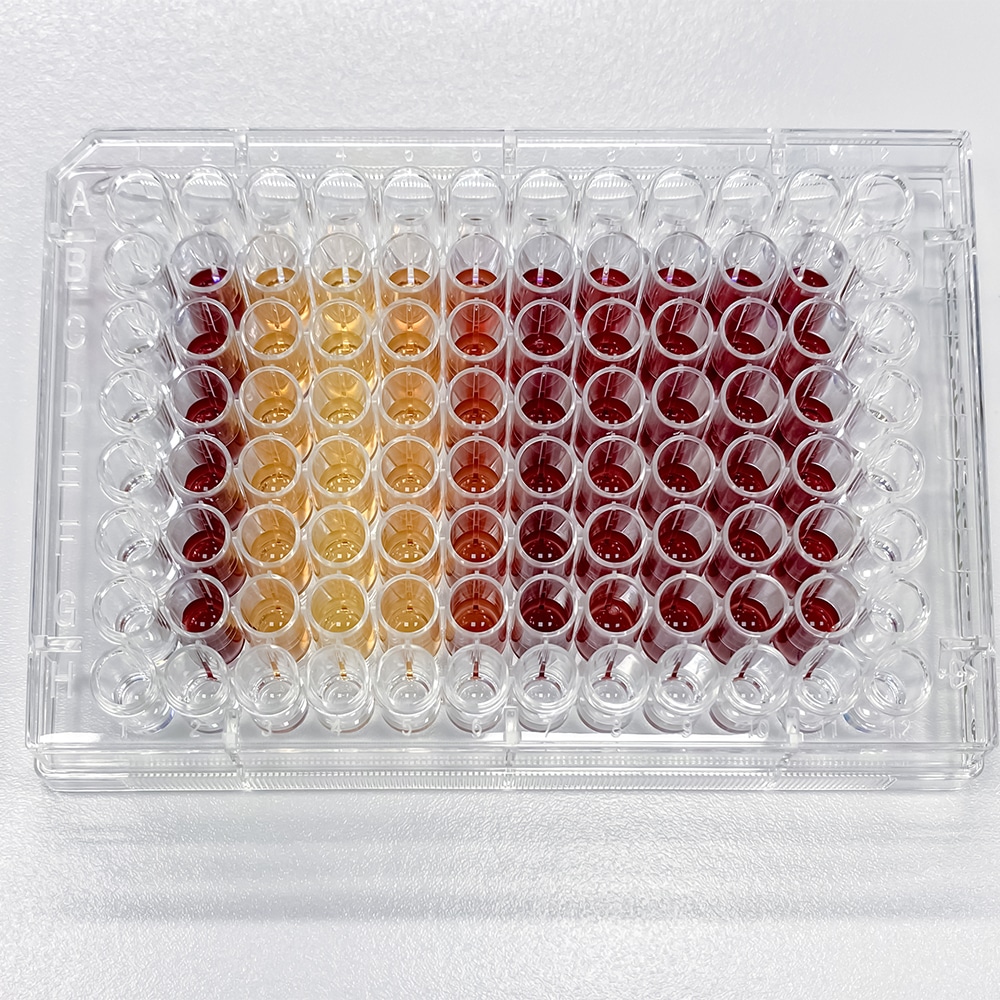

A hemolysis test assesses whether a material causes red blood cells to rupture when in contact with blood. The test simulates exposure by using anticoagulated whole blood and measuring hemoglobin release with a spectrophotometer. The results are categorized as:

- Non-hemolytic if the hemolysis index is <2%

- Slightly hemolytic at 2-5%

- Hemolytic at >5%

Both direct-contact and extract-based testing are performed to ensure the material’s safety under all relevant conditions.

ME-92 Hemolysis Study Summary

ME-92’s proprietary thin dense chrome coating, applied to 304 stainless steel, was tested by NAMSA, an accredited independent lab. The study included both direct-contact and extract testing using pooled rabbit blood.

- Direct Contact Hemolytic Index: 0.7%

- Extract Hemolytic Index: 0.0%

Results confirmed that ME-92 is non-hemolytic under both conditions, far below the 2% threshold required for medical-grade safety.

Why Hemolytic Activity Matters

For surgical tools, implants, and devices that interface with blood, biocompatibility isn’t optional—it’s essential. ME-92’s non-hemolytic performance demonstrates its reliability in safeguarding red blood cells and supporting patient health during invasive procedures.

Partner With Us

At Armoloy, we specialize in biocompatible coatings that meet the highest industry standards. Contact us to learn how ME-92 can elevate your medical device’s biocompatibility and performance.