What is Metal Treating?

Metal treating is a broad term that refers to a variety of processes used to modify the surface and internal properties of metals to enhance performance in specific applications. This includes heat treatment, surface coatings, plating, and other chemical or mechanical methods. Metal treating improves a metal’s hardness, strength, corrosion resistance, wear resistance, and other characteristics.

In this guide, we’ll review common methods of metal treating:

Heat Treatments

The field of heat treatment is vast and constantly evolving, with ongoing innovations driving its expansion. However, only a handful of processes are responsible for the majority of heat-treated parts. Here’s a breakdown of four common types: hardening, annealing, tempering, and quenching.

Hardening

Hardening is a metal treating process used to increase the strength and hardness of metals, primarily steel. In this process, the metal is heated to a high temperature and then rapidly cooled (usually by quenching in water or oil). This rapid cooling locks the metal’s structure into a hardened state, often forming a phase known as martensite, which greatly increases the metal’s wear resistance.

Steel parts hardening in an electric furnace

Annealing

Annealing is the opposite of hardening—it softens metal to improve its ductility and make it more workable. The metal is heated to a specific temperature and then slowly cooled, often in the furnace. This controlled cooling relieves internal stresses, refines the grain structure, and restores the metal’s malleability. Annealing is especially important for metals that need to undergo further shaping or machining.

Metal treating by annealing with propane for jewelry making

Tempering

Tempering follows the hardening process to reduce brittleness. After metal is hardened, it can become too brittle for practical use. In tempering, the metal is reheated to a lower temperature (below its critical point) and then slowly cooled. This allows the metal to retain its hardness while gaining toughness, striking a balance between strength and flexibility.

Quenching

Quenching is the rapid cooling process used in hardening. After the metal is heated to its desired temperature, it is quickly cooled by immersing it in a quenching medium like water, oil, or air. This rapid cooling locks the metal’s microstructure, typically making it harder. However, without tempering, quenched metals can be too brittle for many applications.

Tempering and Quenching Demonstration Video

Click on the video below to view a brief demonstration on the tempering and quenching of metal parts.

A Note on Quenching

Quenching is essential in many heat treatment processes to achieve full strength and hardness. It triggers a martensitic transformation, where the iron and carbon atoms subtly rearrange, dramatically improving the material’s properties. This thermodynamic phenomenon is crucial to modern advancements, enabling transportation, semiconductor manufacturing, and large-scale mechanization. Without it, critical components would either fail or require immense energy due to their size.

Surface Coating and Plating

Surface coating and plating are essential processes used to enhance the surface properties of metals, including corrosion resistance, wear resistance, cost savings, and aesthetics. These processes cover a range of techniques that apply different materials to a metal’s surface, providing protection and extending its service life. Here’s a breakdown of some key surface coating methods.

Electroplating

Electroplating uses an electric current to deposit a thin layer of metal onto the surface of a workpiece. This method typically involves submerging the metal part in a solution containing dissolved metal ions (like nickel, gold, or zinc), with the workpiece acting as the cathode. Electroplating is widely used for corrosion protection, improving conductivity, and adding a decorative finish.

Plating technician performing electroplating of thin dense chrome

Autocatalytic

Autocatalytic, or electroless, plating is a chemical deposition process that applies a uniform metal coating onto a substrate without the use of an external electrical current. This method leverages a chemical reaction between the plating solution and the surface being coated, resulting in a highly consistent layer, even on complex geometries. Commonly used metals include nickel and copper, offering enhanced corrosion protection, and precise thickness control.

Electroless nickel plating bath

Thermal Spraying

Thermal spraying involves heating a material (metallic or non-metallic) to its molten state and then spraying it onto the surface of the metal part. This process forms a protective or functional coating that enhances properties such as wear resistance, heat resistance, and corrosion resistance. Common methods include plasma spraying and flame spraying, both of which are widely applicable in industries like aerospace and automotive.

Plating technician performing thermal spray coating process

Vapor Deposition

Vapor deposition techniques, including Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD), involve vaporizing a material and condensing it onto a substrate to form a thin film. These coatings are highly durable and provide excellent wear resistance and corrosion protection. High-performance tools, aerospace components, and semiconductor devices are a few common candidates for PVD and CVD.

Anodizing

Anodizing is a primary application for aluminum and its alloys. This electrochemical process forms a protective oxide layer on the surface of the metal. The anodized coating improves corrosion resistance, wear resistance, and provides various dyes for decorative purposes. It is widely used in architectural applications and consumer products.

Anodizing comes in an array of colors, from a standard matte-silver finish to vibrant blue.

Phosphating

Phosphating is a chemical process that creates a phosphate coating on steel or zinc surfaces. This process provides corrosion protection, lubricity, and acts as a base for further painting or coating. Phosphating is a common application for the automotive and manufacturing industries.

Each of these surface coating and plating techniques plays a crucial role in extending the life of metal components and enhancing their performance in harsh environments. They are common across industries like aerospace, automotive, electronics, and construction.

Chemical Treatments

Chemical treatments modify the surface composition of metals to enhance properties such as hardness, wear resistance, and corrosion resistance. These treatments often involve diffusing elements into the metal’s surface to create harder, more durable layers. Here’s an overview of key chemical treatments used in the metal industry.

Carburizing

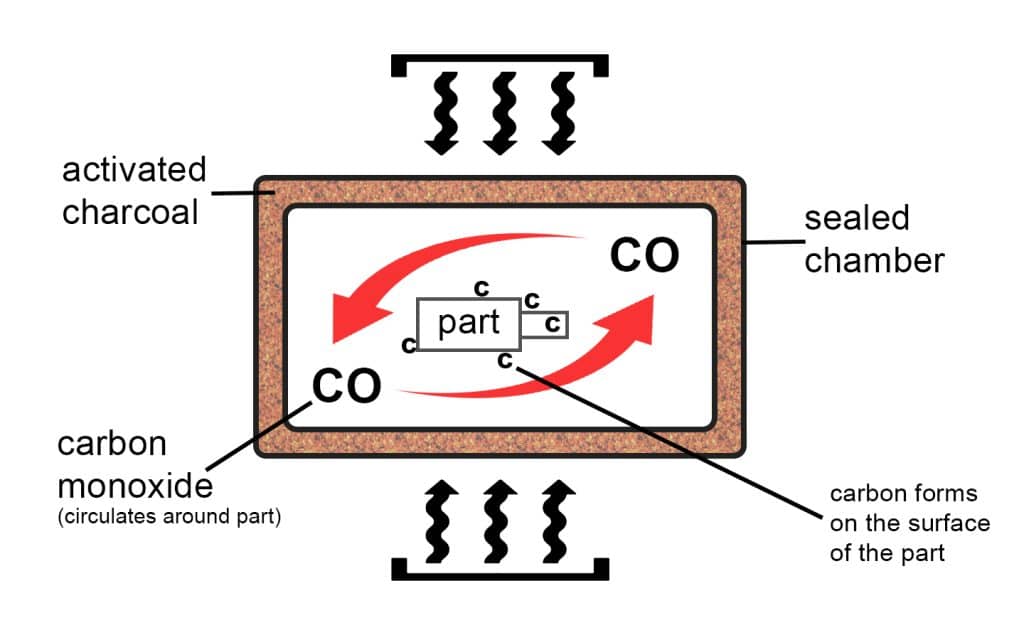

Carburizing is a surface hardening process in which carbon diffuses into the surface of low-carbon steel. This is done by heating the metal in a carbon-rich environment at high temperatures. The result is a hard, wear-resistant outer layer while the core remains softer and more ductile. Carburizing is common in the automotive industry for parts like gears and camshafts that require high surface durability.

Basic diagram of the pack carburizing process

Nitriding

Nitriding is a process where nitrogen diffuses into the surface of metals to form a hard, wear-resistant layer. Unlike carburizing, nitriding performs at lower temperatures, and quenching is not a requirement, making the process less prone to distortion. This method is useful for components like crankshafts, valves, and tools that need higher fatigue and corrosion resistance.

Finished shaft gears after undergoing a nitriding process

Carbonitriding

Carbonitriding is similar to carburizing, but it involves both carbon and nitrogen diffusion into the metal’s surface. This treatment increases surface hardness while also improving toughness and wear resistance. Carbonitriding is frequent in industries that manufacture small components like fasteners and pins.

Boriding

Boriding, also called boronizing, is a specialized case hardening diffusion method that introduces boron atoms into the metal surface, creating a very hard and wear-resistant layer. Metal-boride surfaces have excellent resistance to high temperatures and wear, making this process ideal for applications in extreme environments, such as in oil and gas or chemical industries.

Chromizing

Chromizing is a diffusion process where chromium atoms penetrate the surface of a metal, forming a protective layer. This treatment enhances oxidation and corrosion resistance, especially at high temperatures. Chromizing performs well for parts exposed to extreme heat, such as turbine blades and furnace components.

Chromizing applied on the vanes (blades) of this industrial turbine engine to guard against hot temperature oxidation

Each of these chemical treatments helps improve metal performance for a variety of industrial applications, from automotive and aerospace to oil and gas. These methods help extend the life of metal parts by improving their surface properties without compromising their internal structure.

Enhancing Performance and Durability Across Industries

Metal treating encompasses a wide range of methods—each designed to enhance the performance, durability, and lifespan of metal components. From heat treatments that alter internal structures, to surface coating and plating methods that protect against corrosion and wear, each process serves a specific industrial need. Chemical treatments like carburizing, nitriding, and boriding further tailor surface properties, offering enhanced hardness, fatigue resistance, and protection in extreme environments. Together, these metal treating techniques allow manufacturers to customize metal properties for applications across industries like aerospace, automotive, construction, and beyond, ensuring optimal performance in the most demanding conditions.

Looking for Metal Treating Services?

Have a chat with an Armoloy engineer for more information on our metal treating capabilities.