Armoloy Specifications

What is ASTM A967?

ASTM A967 is the standard specification for chemically treating stainless steel parts through passivation. This process passivates contaminants like free iron and foreign particles from stainless steel surfaces, making them more resistant to corrosion. It forms a thin, protective oxide layer that prevents rust and extends the material’s lifespan.

The specification outlines detailed guidelines for nitric and citric acid treatments tailored to different stainless steel grades. It also requires thorough rinsing to neutralize residual chemicals and lists several tests to confirm passivation, including salt spray, water immersion, boiling water immersion, copper sulfate, high humidity, damp cloth, and potassium ferricyanide-nitric acid.

ASTM A967 is widely used in industries where stainless steel is exposed to corrosive environments or must meet strict cleanliness standards. Standardizing the passivation process helps manufacturers stay consistent, avoid part rejection, and meet expectations across different production runs and supply chain partners.

The Role of ASTM A967 in Chemical Passivation of Stainless Steel

ASTM A967 standardizes the chemical passivation of stainless steel, meeting the performance and quality needs of various industries through these key roles:

- Improving Corrosion Resistance: Outlines methods for removing contaminants, specifically iron, that compromise stainless steel’s natural corrosion resistance.

- Defining Testing Standards: Specifies tests like Salt Spray and Copper Sulfate to confirm effective passivation.

- Customizing Treatments: Offers flexible nitric and citric acid options for different grades and applications.

- Ensuring Consistency: Standardizes processes for reliable stainless steel performance across industries.

- Enhancing Durability: Focuses on treatments and testing to extend material lifespan and reliability.

ASTM A967 helps manufacturers produce stainless steel components that meet high standards for durability and performance in challenging environments.

ASTM A967 Testing Methodology and Results

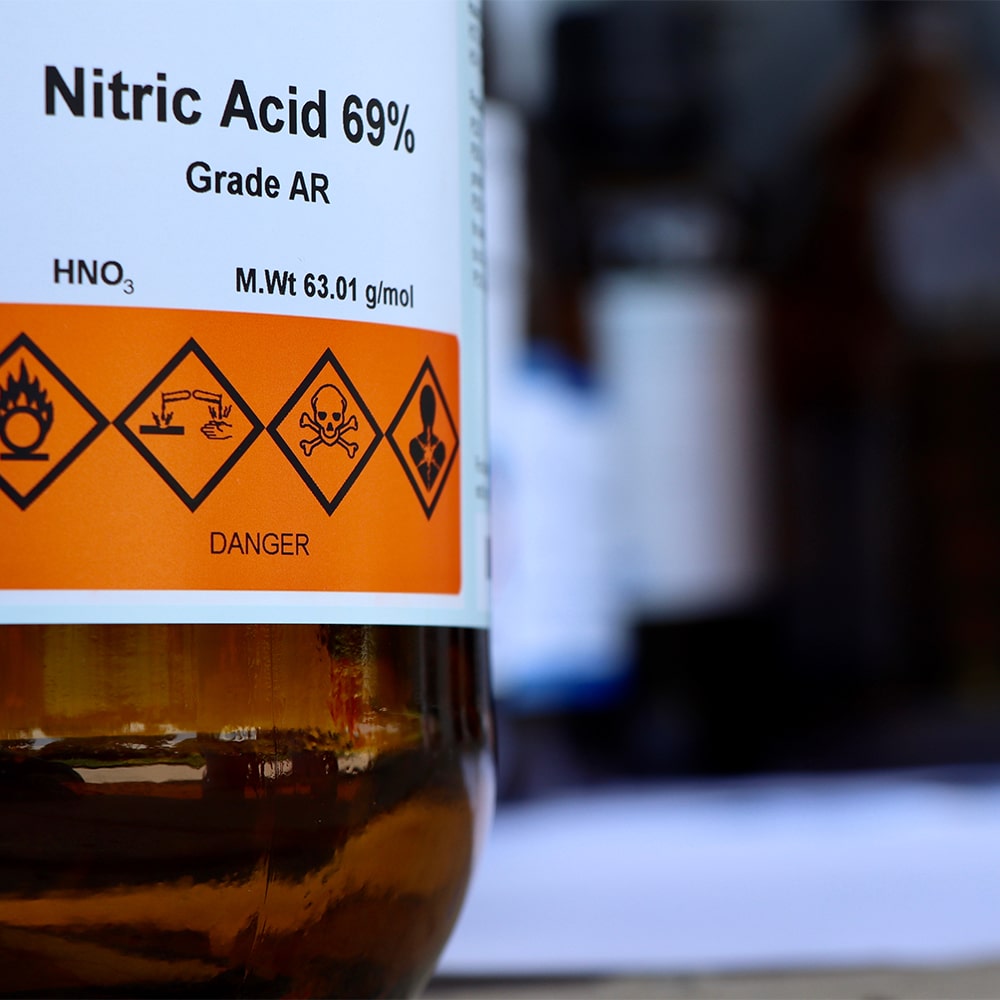

ASTM A967 allows for two chemical passivation options: nitric acid and citric acid. Nitric acid is the traditional choice, known for its cleaning power. Citric acid is a safer, low-toxicity alternative that’s easier to handle and dispose of. The best option depends on factors like alloy type, safety requirements, and the desired level of process control.

To verify successfull passivation, ASTM A967 specifies various tests that check for residual contaminants and confirm that the protective oxide layer has formed. Common test methods include:

- Salt Spray Test: Simulates corrosive conditions to assess rust resistance.

- Water Immersion Test: Submerges parts to detect residual contamination.

- Copper Sulfate Test: Reveals free iron through a color change reaction.

- High Humidity Test: Exposes components to moisture to evaluate corrosion resistance.

- Boiling Water Test: Tests durability by immersing parts in boiling water.

- Potassium Ferricyanide Test: Identifies contaminants on treated surfaces.

- Damp Cloth Test: Assesses resistance to environmental moisture.

Regular testing with ASTM A967 gives manufacturers confidence that their stainless steel parts will last in demanding applications.

Industries that Follow ASTM B733

ASTM A967 supports industries that depend on stainless steel parts to maintain surface integrity and performance over time. Key industries include:

- Aerospace: Ensures stainless steel components, such as fasteners and structural parts, resist corrosion in extreme conditions.

- Automotive: Protects exhaust systems, fuel injectors, and other stainless steel parts from rust and wear, extending vehicle lifespan.

- Defense: Passivation protects stainless steel from corrosion in weapons, vehicles, and infrastructure.

- Food Processing: Maintains the cleanliness and corrosion resistance of stainless steel equipment used in food production, meeting strict hygiene standards.

- Medical Devices: Guarantees stainless steel surgical tools, implants, and instruments that are corrosion-free, safe, and durable.

These industries rely on ASTM A967 to produce stainless steel components that perform reliably and last longer.

Benefits of Working with an ASTM A967 Provider

Precise treatments

Providers use proven methods to treat stainless steel for better corrosion resistance

Consistent quality

Standardized processes deliver consistent, high-quality results for every batch

Flexible solutions

Passivation methods are tailored to your materials and needs

Longer lifespan

Treated components last longer and require less maintenance

Regulatory compliance

Providers meet ASTM A967 standards, which are vital for aerospace and food processing industries

Verified results

Thorough testing confirms treatments work and contaminants are fully removed

Lower costs

Preventing corrosion reduces repair and replacement expenses

Trusted expertise

Experienced providers offer guidance and reliable solutions for your applications

Specifications at Armoloy

Armoloy offers plating solutions that meet ASTM A967 to support both regulatory compliance and individual project needs. Explore common specifications and accreditations we work with, and contact us to find the right solution for your application.

Disclaimer

The information provided on this page, including any descriptions, interpretations, or summaries related to ASTM A967, is offered solely by The Armoloy Corporation for general informational purposes. This content reflects Armoloy’s internal understanding and practical application of ASTM A967 within its own processes and does not constitute official or authorized guidance from ASTM International.

ASTM A967 is a proprietary standard developed and owned by ASTM International. Armoloy makes no claim to ownership of this specification and does not reproduce, quote, or distribute any protected content from the original document. References to ASTM A967 are made in accordance with fair use principles and are intended to illustrate Armoloy’s alignment with widely recognized passivation standards.

This content is not intended to substitute for the official specification, which should be obtained directly from ASTM International. Readers are strongly encouraged to consult the original standard and qualified professionals for definitive technical or compliance information.

The Armoloy Corporation makes no warranties, express or implied, regarding the accuracy, completeness, or applicability of this content and disclaims all liability for any reliance placed upon it. This disclaimer is subject to change without notice and does not create any contractual relationship or obligation.