Armoloy Specifications

What is AMS 2438?

The Role of AMS 2438 in Chrome Plating Standards

By adhering to AMS 2438, manufacturers gain key advantages, including:

- Clear Quality Standards: Precise plating requirements give manufacturers clear targets to meet customer and industry expectations.

- Proven Performance: Testing protocols verify coatings can withstand stress, reducing the risk of failure.

- Longer-Lasting Components: Improved durability and wear resistance lower maintenance needs and downtime.

- Streamlined Compliance: AMS 2438 helps manufacturers meet aerospace and other industry-specific regulations, satisfying audits and facilitating global market acceptance.

- Customer Confidence: Demonstrates a commitment to quality, strengthening trust and competitive positioning.

AMS 2438 sets the standard for precision and longevity in thin dense chrome plating, driving innovation in industries that depend on it.

AMS 2438 Testing Methodology & Results

To align with the performance goals of AMS 2438, Armoloy applies rigorous internal testing protocols that typically include hardness, adhesion, corrosion resistance, abrasion resistance, and hydrogen embrittlement resistance. These tests help ensure our coatings meet industry expectations for durability and precision. For full test requirements, consult the official AMS 2438 specification from SAE International.

- Hardness Test: Measures resistance to deformation under pressure using microhardness testing techniques, ensuring it can withstand mechanical stress.

- Adhesion Test: Confirms strong bonding to the substrate to prevent delamination or failure.

- Corrosion Resistance Test: Assesses protection against harsh environments using salt fog or porosity tests.

- Abrasion Resistance Test: Evaluates wear resistance through methods like the Taber Abrasion Test.

- Hydrogen Embrittlement Test: Ensures the component resists brittleness caused by hydrogen absorption.

AMS 2438 upholds strict quality assurance through sampling, periodic testing, and precise documentation to maintain consistent plating performance.

Industries that Use AMS 2438

Although developed by SAE’s Aerospace Material Specifications Committee B, AMS 2438 applies across industries that rely on thin dense chrome coatings for critical components. These include:

- Aerospace: Protects landing gear, engine parts, and hydraulic systems under extreme conditions.

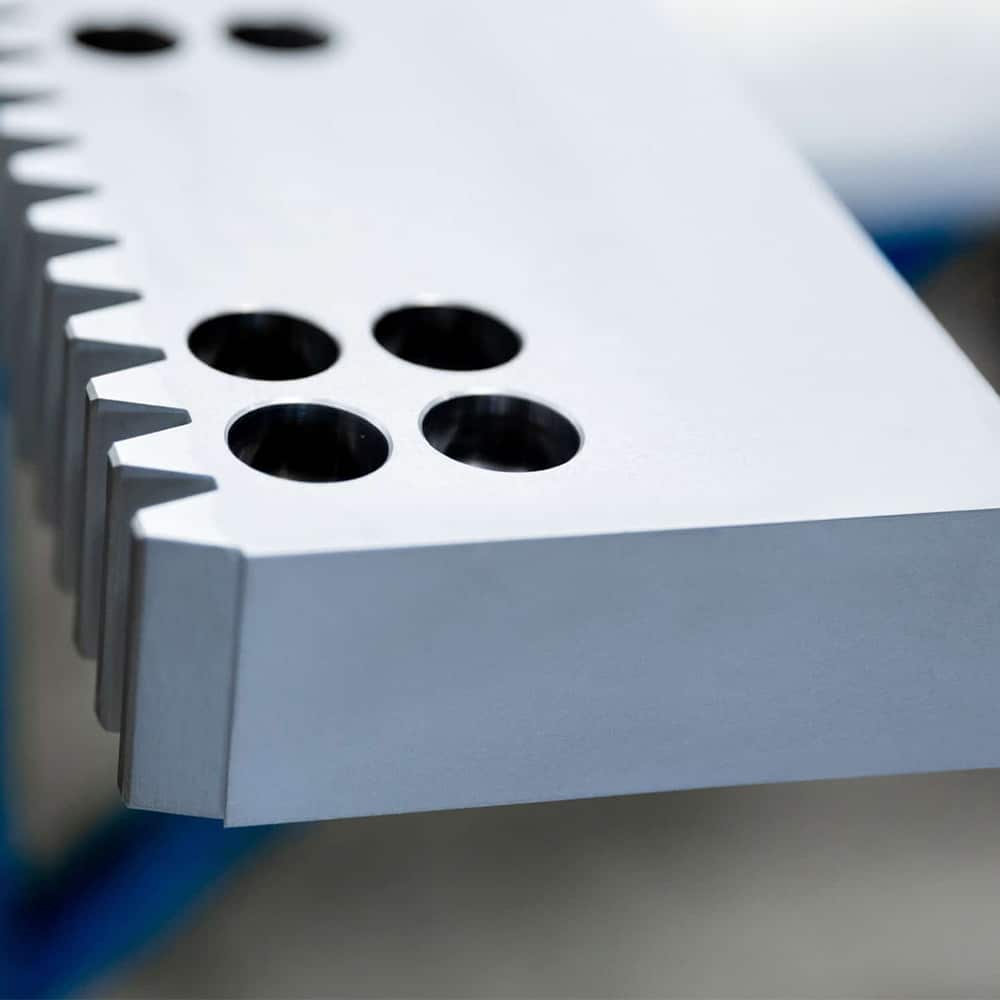

- Automotive: Enhances pistons, shafts, and gears for high-friction performance.

- Bearings: Improves wear resistance for longer operational life in high-performance machinery.

- Defense: Ensures military equipment meets strict reliability standards.

- Medical: Preserves the integrity of surgical tools and implants through repeated use and sterilization.

From aerospace to medical and beyond, AMS 2438 drives precision, reliability, and longevity in chrome-plated components.

Benefits of Working with an AMS 2438 Provider

High quality standards

Providers meeting AMS 2438 follow strict specifications to deliver consistent quality and performance for coated parts

Improved durability

Enhanced wear and corrosion resistance extend component life in demanding environments

Precision and uniformity

AMS 2438 guidelines ensure consistent coating thickness and application, maintaining uniform performance across all plated parts

Process consistency

Standardized plating methods ensure repeatable, high-quality results

Regulatory compliance

Partnering with an AMS 2438-aligned provider supports adherence to industry and aerospace regulations

Traceable documentation

Comprehensive records of plating, testing, contracts, purchase orders, and more offer full traceability for audit and compliance needs

Versatile applications

AMS 2438-compliant coatings support a range of industries and performance needs

Expert guidance

Reliable providers who understand the nuances of thin dense chrome plating offer strategic guidance on the best approach for your application

Specifications at Armoloy

Armoloy offers plating solutions that meet AMS 2438 to support both regulatory compliance and individual project needs. Explore common specifications and accreditations we work with, and contact us to find the right solution for your application.

Disclaimer

The information presented on this page, including any descriptions, interpretations, or summaries related to AMS 2438, is provided solely by The Armoloy Corporation for general informational purposes. This content reflects Armoloy’s internal understanding and practical application of AMS 2438 within its own processes and does not constitute official or authorized guidance from SAE International.

AMS 2438 is a proprietary standard developed and owned by SAE International. Armoloy makes no claim to ownership of this specification and does not reproduce, quote, or distribute any protected content from the original document. Any reference to AMS 2438 is made in accordance with fair use principles and is intended to illustrate Armoloy’s commitment to industry standards in chromium plating processes.

This content is not intended to substitute for the official specification, which should be obtained directly from SAE International. Readers are strongly encouraged to consult the original standard and qualified professionals for definitive technical or compliance information.

The Armoloy Corporation makes no warranties, express or implied, regarding the accuracy, completeness, or applicability of this content and disclaims all liability for any reliance placed upon it. This disclaimer is subject to change without notice and does not create any contractual relationship or obligation.