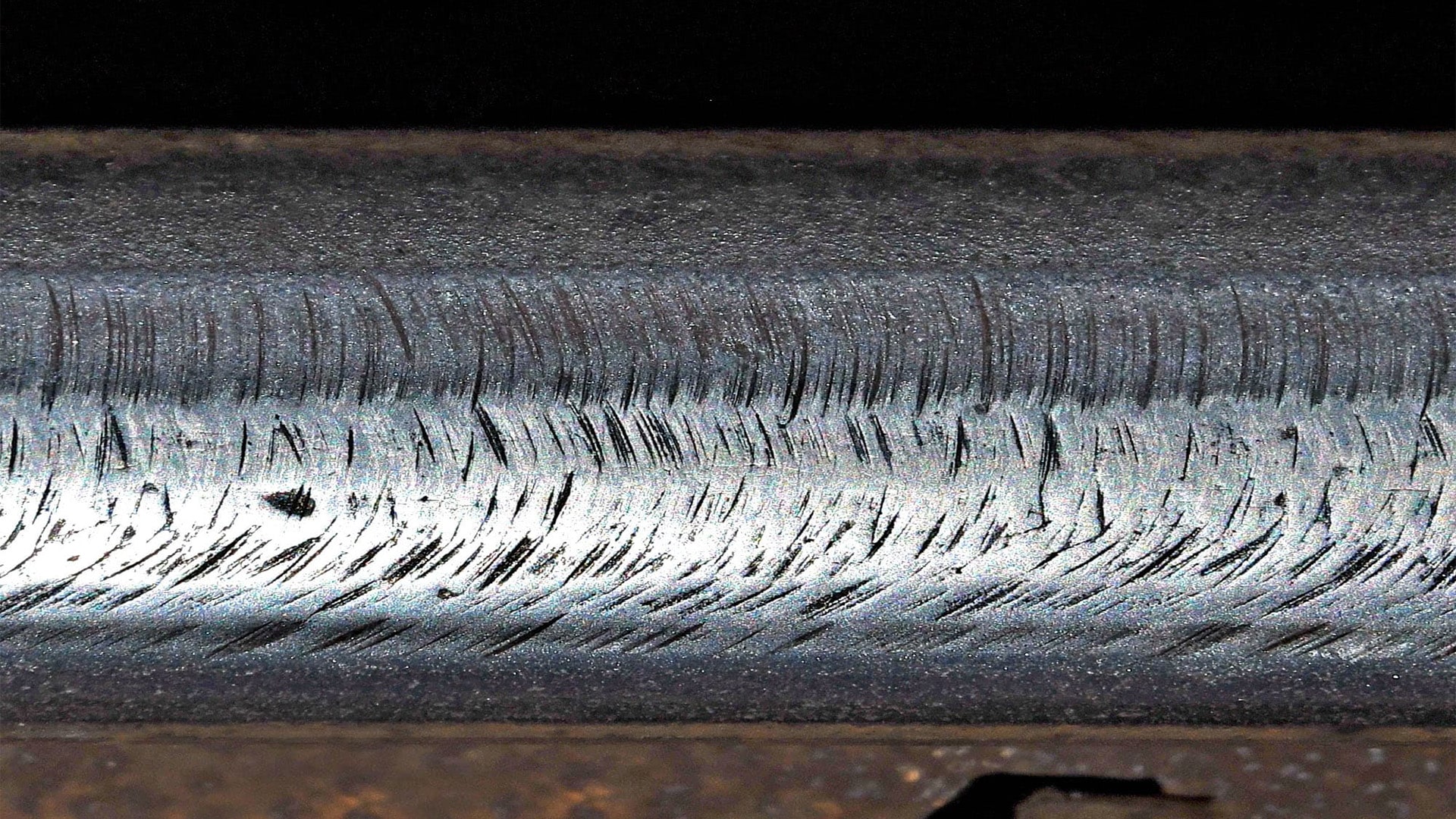

Rolling contact fatigue occurs when repeated rolling or sliding contact between surfaces generates high localized stresses below the surface. Over time, these stresses create subsurface cracks that eventually propagate to the surface, causing spalling, pitting, or flaking. This failure mode is common in bearings, gears, and raceways that experience continuous rolling motion under load.

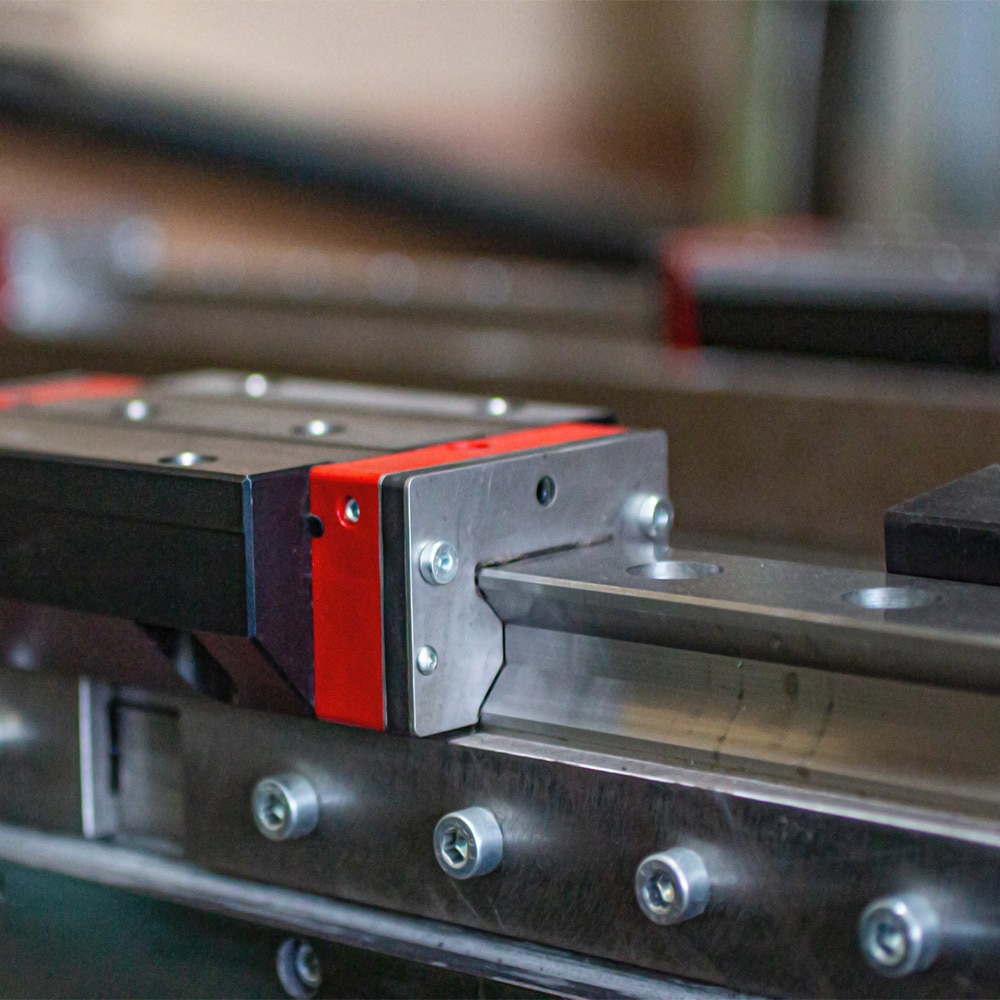

Fretting wear, by contrast, is driven by surface-level micro-movements under load, causing adhesion, pitting, and oxidation where parts experience small oscillations without full rolling motion.

While both mechanisms can lead to surface damage and eventual failure, rolling contact fatigue originates below the surface, while fretting wear is a surface-driven phenomenon.